AIRFOILS (Cont.)

C. Inspection

A ground check of entire deicer system should be made at least every 100 hours.

Before checking system, all deicers should be inspected for damaged areas and repaired according to

procedure in this section outlining cold patch or vulcanized repairs. In order to check system, refer to

Chart 2 and the paragraph Final Test and Adjustment of Pneumatic System for operating pressure and

check procedures.

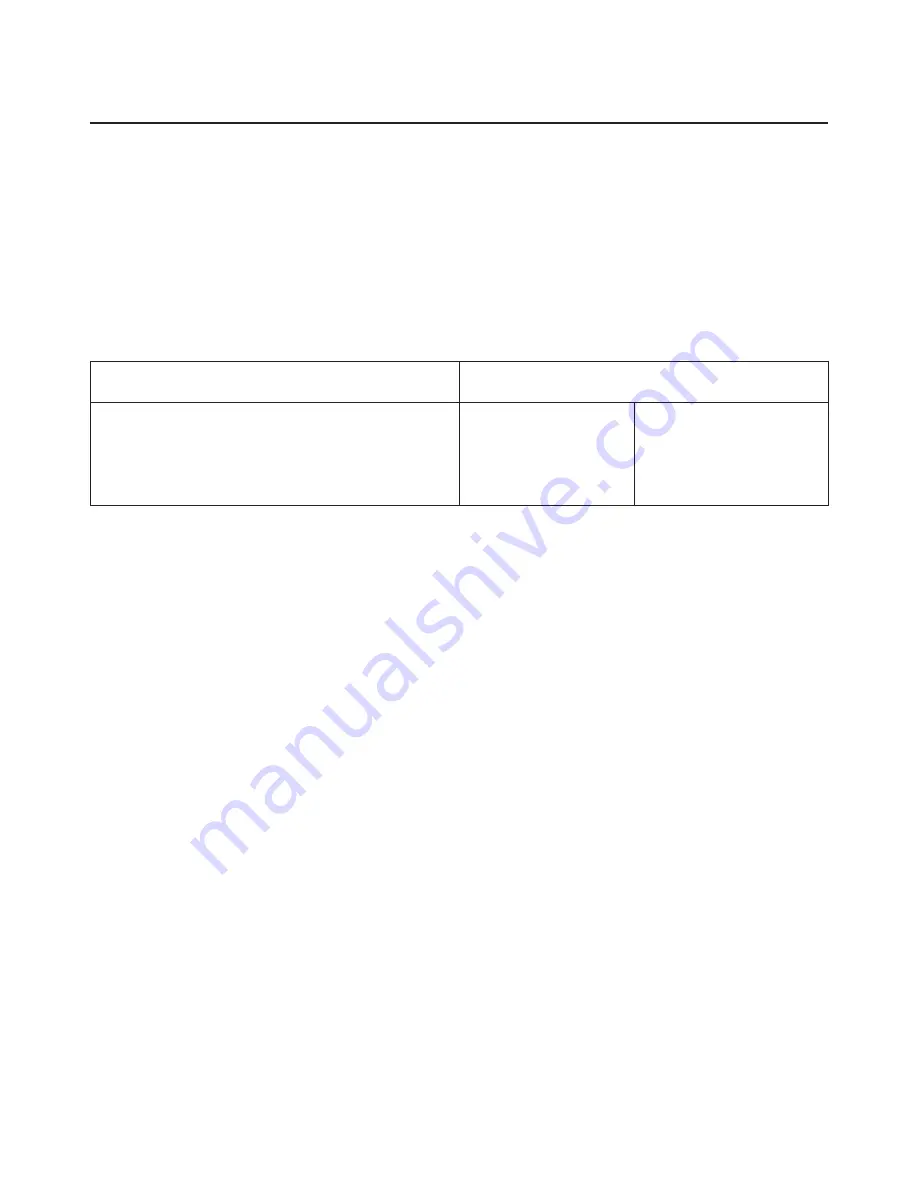

CHART 2

OPERATING PRESSURES

D. Ground Procedure

After test pressure range is established, connect an external source of air providing this pressure and a

pressure gauge to pneumatic deice line at manifold assembly. Disconnect deice line from manifold to

accomplish test. Deicer system should be within one psig of recommended operating pressure with

each inflation cycle.

If deicers do not reach operating pressure, check inflation time to ascertain that solenoid valves are

open specified length of time (six seconds). If this is not cause of trouble, or if boots deflate slowly,

lines or valves may be plugged; then lines should be disconnected and blown clear.Check timing of

system through several complete cycles. Boots ON six seconds, then OFF. Wing and empennage boots

operate separately. If cycle time is off specified time, determine and correct the difficulty.

Inflation must be rapid to provide efficient deicing. Deflation should be complete before next inflation

cycle of the boots.

E. 100 Hour Inspection

(1) Make the following checks at each 100 hour inspection of airplane:

(a) Carefully inspect deicers for evidence of damage or deterioration. Repair or replace damaged

boots.

(b) Resurface boots showing signs of considerable wear or deterioration.

(c) Inspect all pneumatic deicing system hose connections. Replace deteriorated sections on non-

kink hoses.

(d) Check operation of boots and operating pressure of the system as outlined in this section.

(e) If new or replacement boots have been installed, check tube inflation to make ensure air con-

nection stems have been properly connected.

(f) Disconnect all system drain lines and check for proper drainage.

(g) Check on-off control switch for freedom of action. Check associated electric wiring.

(h) Clean or replace air filters.

PIPER AIRCRAFT

PA-32R-301/301T

MAINTENANCE MANUAL

30-10-00

Page 30-9

Reissued: July 1, 1993

2H3

Recommended OperatingPressure

Test Pressure

PSIG

PSIG

Minimum

Maximum

15

13

17

18

16

20

Summary of Contents for PA-32R-301T SARATOGA S

Page 26: ...CHAPTER 4 AIRWORTHINESS LIMITATIONS 1C1 ...

Page 29: ...CHAPTER 5 TIME LIMITS MAINTENANCE CHECKS 1C4 ...

Page 53: ...CHAPTER 6 DIMENSIONS AND AREAS 1D6 ...

Page 64: ...CHAPTER 7 LIFTING AND SHORING 1D21 ...

Page 68: ...CHAPTER 8 LEVELING AND WEIGHING 1E1 ...

Page 72: ...CHAPTER 9 TOWING AND TAXIING 1E5 ...

Page 76: ...CHAPTER 10 PARKING AND MOORING 1E9 ...

Page 80: ...CHAPTER 11 REQUIRED PLACARDS 1E13 ...

Page 92: ...CHAPTER 12 SERVICING 1F1 ...

Page 126: ...CHAPTER 20 STANDARD PRACTICES AIRFRAME 1G17 ...

Page 127: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 139: ...CHAPTER 21 ENVIRONMENTAL SYSTEMS 1H5 ...

Page 188: ...CHAPTER 22 AUTOFLIGHT 1J7 ...

Page 193: ...CHAPTER 23 COMMUNICATIONS 1J12 ...

Page 203: ...CHAPTER 24 ELECTRICAL POWER 1J22 ...

Page 263: ...CHAPTER 25 EQUIPMENT FURNISHINGS 2A13 ...

Page 269: ...CHAPTER 27 FLIGHT CONTROLS 2A20 ...

Page 332: ...CHAPTER 28 FUEL 2D11 ...

Page 363: ...CHAPTER 29 HYDRAULIC POWER 2E18 ...

Page 404: ...CHAPTER 30 ICE AND RAIN PROTECTION 2G16 ...

Page 470: ...CHAPTER 32 LANDING GEAR 3A13 ...

Page 550: ...CHAPTER 33 LIGHTS 3D24 ...

Page 562: ...CHAPTER 34 NAVIGATION AND PITOT STATIC 3E12 ...

Page 582: ...CHAPTER 35 OXYGEN 3F8 ...

Page 604: ...CHAPTER 37 VACUUM 3G6 ...

Page 616: ...CHAPTER 39 3G18 ELECTRIC ELECTRONIC PANELS MULTIPURPOSE PARTS ...

Page 620: ...CHAPTER 51 STRUCTURES 3G22 ...

Page 636: ...CHAPTER 52 DOORS 3H14 ...

Page 650: ...CHAPTER 55 STABILIZERS 3I4 ...

Page 662: ...CHAPTER 56 WINDOWS 3I16 ...

Page 670: ...CHAPTER 57 WINGS 3I24 ...

Page 688: ...CHAPTER 61 PROPELLER 3J18 ...

Page 704: ...CHAPTER 70 STANDARD PRACTICES ENGINES 3K10 ...

Page 708: ...CHAPTER 71 POWER PLANT 3K14 ...

Page 737: ...CHAPTER 73 ENGINE FUEL SYSTEM 4A13 ...

Page 749: ...CHAPTER 74 IGNITION 4B1 ...

Page 783: ...CHAPTER 77 ENGINE INDICATING 4C11 ...

Page 793: ...CHAPTER 78 EXHAUST 4C21 ...

Page 801: ...CHAPTER 79 OIL 4D5 ...

Page 805: ...CHAPTER 80 STARTING 4D9 ...

Page 819: ...CHAPTER 81 TURBINES 4D23 ...

Page 833: ...CHAPTER 91 CHARTS WIRING DIAGRAMS 4E13 ...