SERVICE PROCEDURES.

Since the alternator and regulator are designed for use on only one polarity system, the following procedures

must be observed when working on the charging circuit. Failure to observe these service procedures will result in

serious damage to the electrical equipment.

1. When installing a battery, always make sure the ground polarity of the battery and the ground polarity of

the alternator are the same.

2. When connecting a booster battery, make certain to connect the negative battery terminals together and

the positive battery terminals together.

3. When connecting a charger to the battery, connect the charger positive lead to the battery positive

terminal and the charger negative lead to the battery negative terminal.

4. Never operate the alternator on an open circuit. Make absolutely certain all connections in the circuit are

secure.

5. Do not short across or ground any of the terminals on the alternator or regulator.

6. Do not attempt to polarize the alternator.

SERVICING BATTERY.

The battery should be checked for fluid level, but must not be filled above the baffle plates. A hydrometer

check should be performed to determine the percent of charge in the battery. All connections must be clean and

tight. (Refer to Chart 2404)

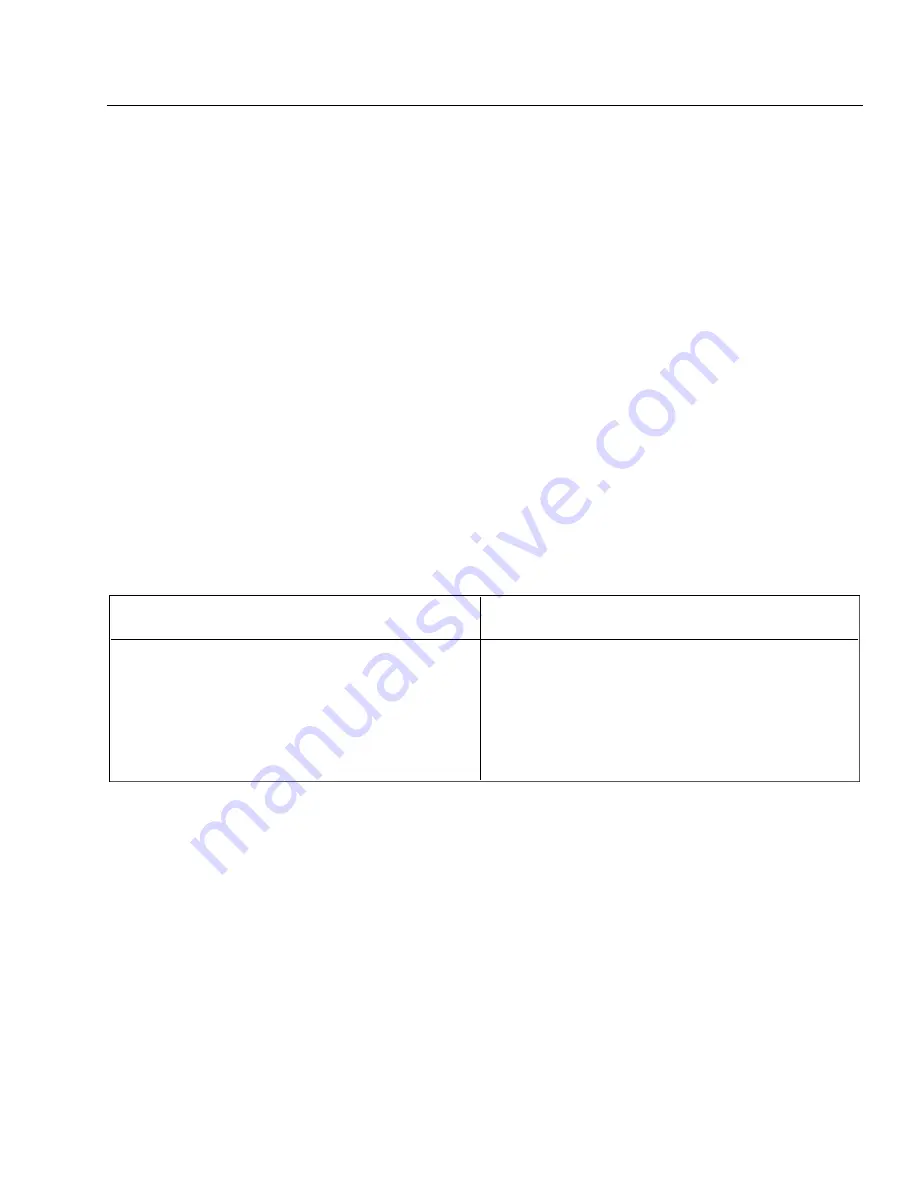

CHART 2404. HYDROMETER READING AND BATTERY CHARGE PERCENT

REMOVAL OF BATTERY.

1. Open aircraft nose section.

2. Disconnect the four cam locks from the battery box cover and remove the cover.

— CAUTION —

A LWAYS REMOVE THE GROUND CABLEFIRST AND INSTALL IT LAST

TO PREVENT ACCIDENTAL SHORT CIRCUITING OR ARCING.

3. Disconnect the battery cables.

4. Lift the battery from the box.

Hydrometer Reading

Percent of Charge

1280

100

1250

75

1220

50

1190

25

1160

Very little useful capacity

1130 or below

discharged

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

2 4 - 3 2 - 0 2

Page 24-13

Revised: May 15, 1989

1J1

PIPER AIRCRAFT

Summary of Contents for SEMINOLE PA-44-180

Page 38: ...CHAPTER DIMENSIONS AND AREAS 1B14...

Page 49: ...CHAPTER LIFTING AND SHORING 1C1...

Page 53: ...CHAPTER LEVELING AND WEIGHING 1C5...

Page 58: ...CHAPTER TOWING AND TAXIING 1C10...

Page 62: ...CHAPTER PARKING AND MOORING 1C14...

Page 65: ...CHAPTER REQUIRED PLACARDS 1C17...

Page 70: ...CHAPTER SERVICING 1C22...

Page 98: ...CHAPTER STANDARD PRACTICES AIRFRAME 1E2...

Page 108: ...CHAPTER ENVIRONMENTAL SYSTEM 1E12...

Page 189: ...CHAPTER AUTOFLIGHT 1H21...

Page 192: ...CHAPTER COMMUNICATIONS 1H24...

Page 202: ...CHAPTER ELECTRICAL POWER 1I10...

Page 228: ...CHAPTER EQUIPMENT FURNISHINGS 1J12...

Page 233: ...CHAPTER FIRE PROTECTION 1J17...

Page 238: ...CHAPTER FLIGHT CONTROLS 1J24...

Page 304: ...2A18 CHAPTER FUEL...

Page 325: ...2B17 CHAPTER HYDRAULIC POWER...

Page 357: ...2D1 CHAPTER ICE AND RAIN PROTECTION...

Page 414: ...CHAPTER LANDING GEAR 2F13...

Page 479: ...2I6 CHAPTER LIGHTS...

Page 488: ...2I16 CHAPTER NAVIGATION AND PITOT STATIC...

Page 503: ...2J7 CHAPTER OXYGEN...

Page 524: ...2K6 CHAPTER VACUUM...

Page 535: ...2K19 CHAPTER ELECTRICAL ELECTRONIC PANELS AND MULTIPURPOSE PARTS...

Page 546: ...INTENTIONALLY LEFT BLANK PA 44 180 180T AIRPLANE MAINTENANCE MANUAL 2L6 PIPER AIRCRAFT...

Page 547: ...2L7 CHAPTER STRUCTURES...

Page 582: ...CHAPTER DOORS 3A18...

Page 593: ...CHAPTER STABILIZERS 3B8...

Page 604: ...CHAPTER WINDOWS 3B22...

Page 611: ...CHAPTER WINGS 3C10...

Page 624: ...CHAPTER PROPELLER 3D1...

Page 643: ...CHAPTER POWER PLANT 3D21...

Page 667: ...CHAPTER ENGINE FUEL SYSTEM 3F1...

Page 681: ...CHAPTER IGNITION 3F16...

Page 712: ...CHAPTER ENGINE INDICATING 3H1...

Page 730: ...CHAPTER EXHAUST 3H19...

Page 734: ...CHAPTER OIL 3I1...

Page 743: ...CHAPTER STARTING 3I11...

Page 755: ...CHAPTER TURBINES 3J1...