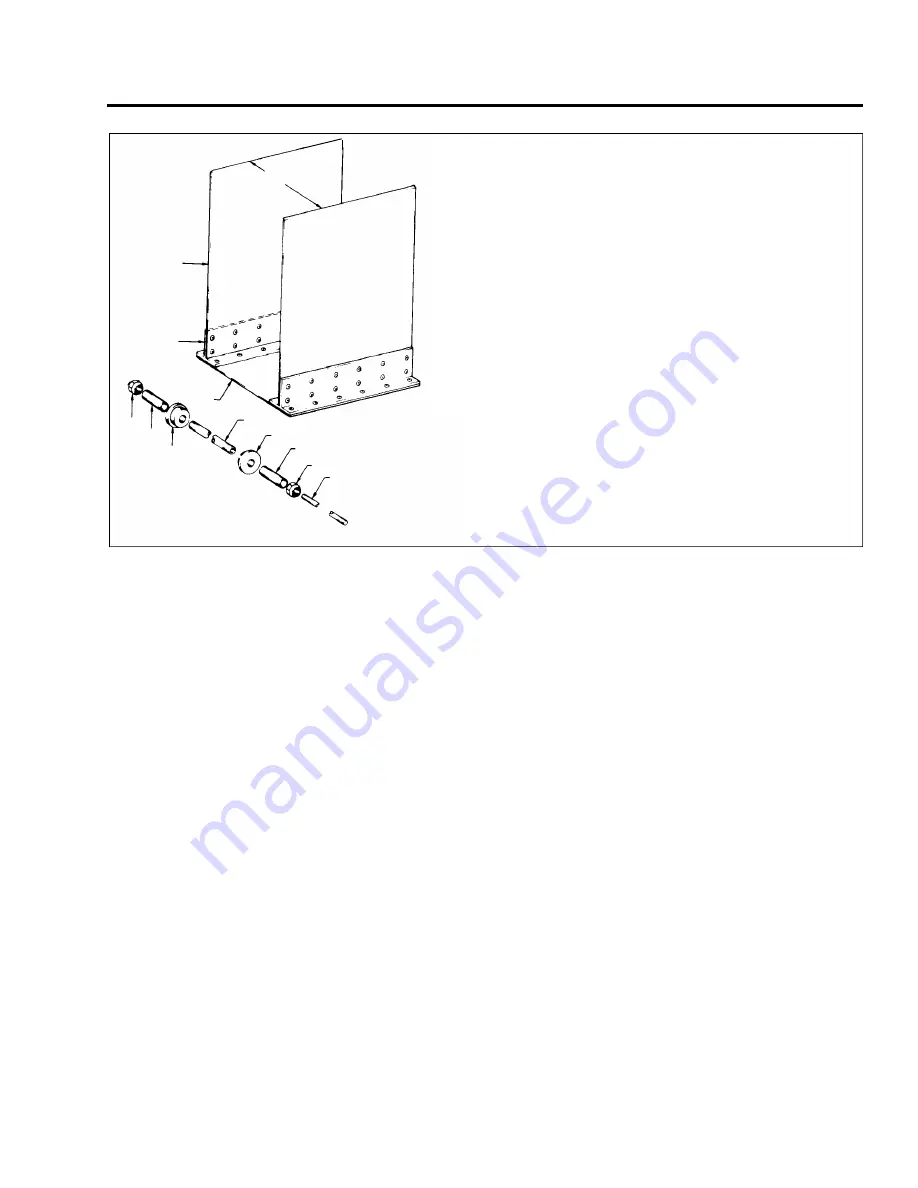

Figure 91-1. Tire Balancer Fixture

TIRE BALANCER BUILDING INSTRUCTIONS.

1. Chamfer top edges of -3 sides, leaving 1/16 inch flat on top inboard edge. Rivet -2 tee’s to -3 sides using

AN 470-ADS rivets 2” spacing. Use AN 426-ADS rivets 2” center to center to secure -2 tee’s to - 1 base. If

tee extrusion is unavailable, heavy angle extrusion could be used. -3 sides must be vertical.

2. The -4 axle must slide through the -8 pipe. The -5 nuts were made by reaming the existing threads in the

AN 365-624 nuts with an R drill, then tapping with a 1/8-27 pipe tap.

3. The -6 spacers were made from 1/2 inch aluminum tubing. The two lengths of spacers are suitable for

balancing most any aircraft wheel.

4. The -7 bushings may be made from one inch phenolic or aluminum using a 1-1/2 inch hole saw to cut out

the smaller bushing and a 1-3/4 hole saw to cut out the larger. By inserting a 1/4 inch long threaded bolt

through the pilot hole and securing with a washer and nut, a drill press and file may be used to make the off-

set on the bushing. The turned-down part should just slide inside the bearing race. Ream the pilot hole to

slide over the -8 pipe threads.

5. The -8 pipe was made from a piece of 1/8 inch black pipe and threaded with a 1/8-27 pipe die. Thread 3

inches in from each end of the pipe.

9.375

The following list of materials were used in making the balancer:

1 ea. Base

12 x 11

0.190 2024 T3 clad aluminum alloy

2 ea. Tee

2.5 x 2 x 11

0.190 2024 T4 extruded aluminum alloy

2 ea. Sides

14 x 11

0.125 2024 T3 clad aluminum alloy

1 ea. Axle

0.125 x 10.25

4130 Steel, normalized

2 ea. Nuts

AN 365-624

2 ea. Spacer

0.50 x 2.25

5052-0 aluminum tubing

2 ea. Spacer

0.50 x 1.25

5052-0 aluminum tubing

2 ea. Bushing

1.480 x 1.625 x 1.00

phenolic or aluminum

2 ea. Bushing

2.240 x 1.37 x 1.00

phenolic or aluminum

1 ea. Pipe

1/8 x 9.3

black steel pipe

*

2 ea. Bearings

Save two of each size worn wheel bearing from

previous inspections.

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

9 1 - 0 4 - 0 0

Page 91-06

Revised: May 15, 1989

4B1

PIPER AIRCRAFT

Summary of Contents for SEMINOLE PA-44-180

Page 38: ...CHAPTER DIMENSIONS AND AREAS 1B14...

Page 49: ...CHAPTER LIFTING AND SHORING 1C1...

Page 53: ...CHAPTER LEVELING AND WEIGHING 1C5...

Page 58: ...CHAPTER TOWING AND TAXIING 1C10...

Page 62: ...CHAPTER PARKING AND MOORING 1C14...

Page 65: ...CHAPTER REQUIRED PLACARDS 1C17...

Page 70: ...CHAPTER SERVICING 1C22...

Page 98: ...CHAPTER STANDARD PRACTICES AIRFRAME 1E2...

Page 108: ...CHAPTER ENVIRONMENTAL SYSTEM 1E12...

Page 189: ...CHAPTER AUTOFLIGHT 1H21...

Page 192: ...CHAPTER COMMUNICATIONS 1H24...

Page 202: ...CHAPTER ELECTRICAL POWER 1I10...

Page 228: ...CHAPTER EQUIPMENT FURNISHINGS 1J12...

Page 233: ...CHAPTER FIRE PROTECTION 1J17...

Page 238: ...CHAPTER FLIGHT CONTROLS 1J24...

Page 304: ...2A18 CHAPTER FUEL...

Page 325: ...2B17 CHAPTER HYDRAULIC POWER...

Page 357: ...2D1 CHAPTER ICE AND RAIN PROTECTION...

Page 414: ...CHAPTER LANDING GEAR 2F13...

Page 479: ...2I6 CHAPTER LIGHTS...

Page 488: ...2I16 CHAPTER NAVIGATION AND PITOT STATIC...

Page 503: ...2J7 CHAPTER OXYGEN...

Page 524: ...2K6 CHAPTER VACUUM...

Page 535: ...2K19 CHAPTER ELECTRICAL ELECTRONIC PANELS AND MULTIPURPOSE PARTS...

Page 546: ...INTENTIONALLY LEFT BLANK PA 44 180 180T AIRPLANE MAINTENANCE MANUAL 2L6 PIPER AIRCRAFT...

Page 547: ...2L7 CHAPTER STRUCTURES...

Page 582: ...CHAPTER DOORS 3A18...

Page 593: ...CHAPTER STABILIZERS 3B8...

Page 604: ...CHAPTER WINDOWS 3B22...

Page 611: ...CHAPTER WINGS 3C10...

Page 624: ...CHAPTER PROPELLER 3D1...

Page 643: ...CHAPTER POWER PLANT 3D21...

Page 667: ...CHAPTER ENGINE FUEL SYSTEM 3F1...

Page 681: ...CHAPTER IGNITION 3F16...

Page 712: ...CHAPTER ENGINE INDICATING 3H1...

Page 730: ...CHAPTER EXHAUST 3H19...

Page 734: ...CHAPTER OIL 3I1...

Page 743: ...CHAPTER STARTING 3I11...

Page 755: ...CHAPTER TURBINES 3J1...