OPERATIONS

Sept-2018

47

OPERATIONS

Prior to plasma cutting, the operator must prepare the program and machine so that

the correct part is cut, the part is cut in the correct location on the raw material, and

the part is of good quality. In order to do this, the operator must go through the

following checklist:

✓

Insert the correct consumables into the plasma torch

✓

Set the current and gas pressure on the plasma power supply

✓

Load a program into the CNC control memory

✓

Jog the machine to the starting location

✓

Set the correct initial height and arc voltage on the Torch Height Controller

✓

Zero the torch

✓

Set the correct cutting speed

✓

Set the correct kerf offset

The following chapter will get the operator familiar with navigating the CNC control,

and describes how to perform these tasks.

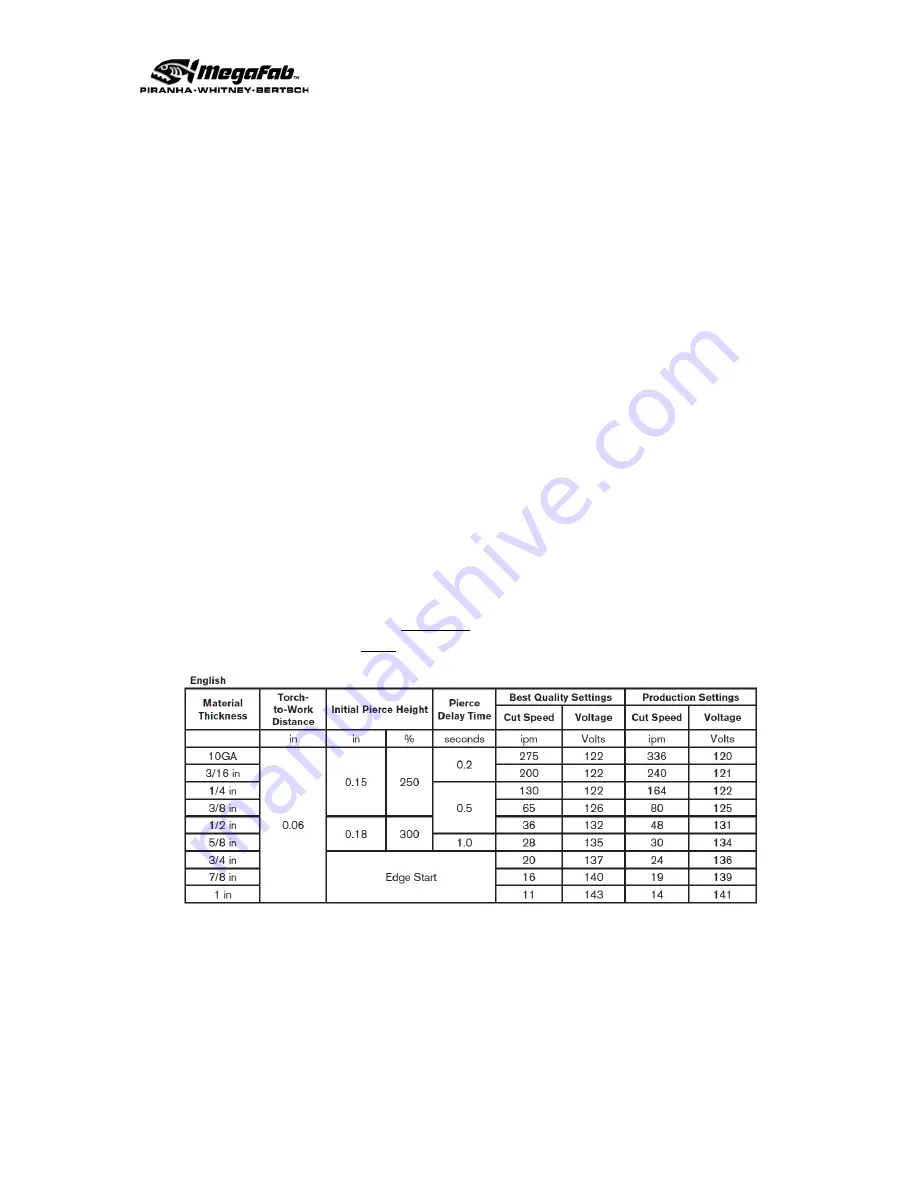

Note that part quality is determined by selection of proper consumables, as well as

correct setup of gas flow (air), cutting speed, and height control. Failure to set these

correctly will result in poor quality parts, or the inability to cut a part at all. Refer to

the Operations Manual of the plasma system for cut charts which supply the correct

setting for these parameters. An example of a cut chart is shown below. Make sure

you refer to the cut chart for your plasma system

– not the information below.

Summary of Contents for CNC Plasma Cutting Table

Page 2: ......

Page 4: ...TABLE OF CONTENTS Sept 2018 4...

Page 22: ...SAFETY Sept 2018 22...

Page 24: ...INSTALLATION Sept 2018 24...

Page 88: ...PROGRAMMING Sept 2018 88...

Page 117: ...PIPE CUTTING ATTACHMENT Sept 2018 117 Pipe Supports Pipe Cutter Base...

Page 124: ...PIPE CUTTING ATTACHMENT Sept 2018 124...

Page 128: ...PIPE CUTTING ATTACHMENT Sept 2018 128 j Then press F2 SYSTEM to see the following...

Page 136: ...PIPE CUTTING ATTACHMENT Sept 2018 136...

Page 140: ...WATER MIST CHILLER Sept 2018 140...

Page 144: ...APPENDIX A FastCAM SETUP Sept 2018 144 4 Choose the functions you need and Enter...

Page 154: ...APPENDIX A FastCAM SETUP Sept 2018 154...

Page 159: ...APPENDIX A FastCAM SETUP Sept 2018 159...

Page 164: ...APPENDIX A FastCAM SETUP Sept 2018 164...

Page 170: ...APPENDIX B Parametric Shape Library Sept 2018 170 9 Fla X 10 Lad 11 Rec 12 Rec8...

Page 172: ...APPENDIX B Parametric Shape Library Sept 2018 172 19 Rec 20 Rec c 21 Circle4 22 Rec...

Page 174: ...APPENDIX B Parametric Shape Library Sept 2018 174...