MAINTENANCE

Sept-2018

89

MAINTENANCE

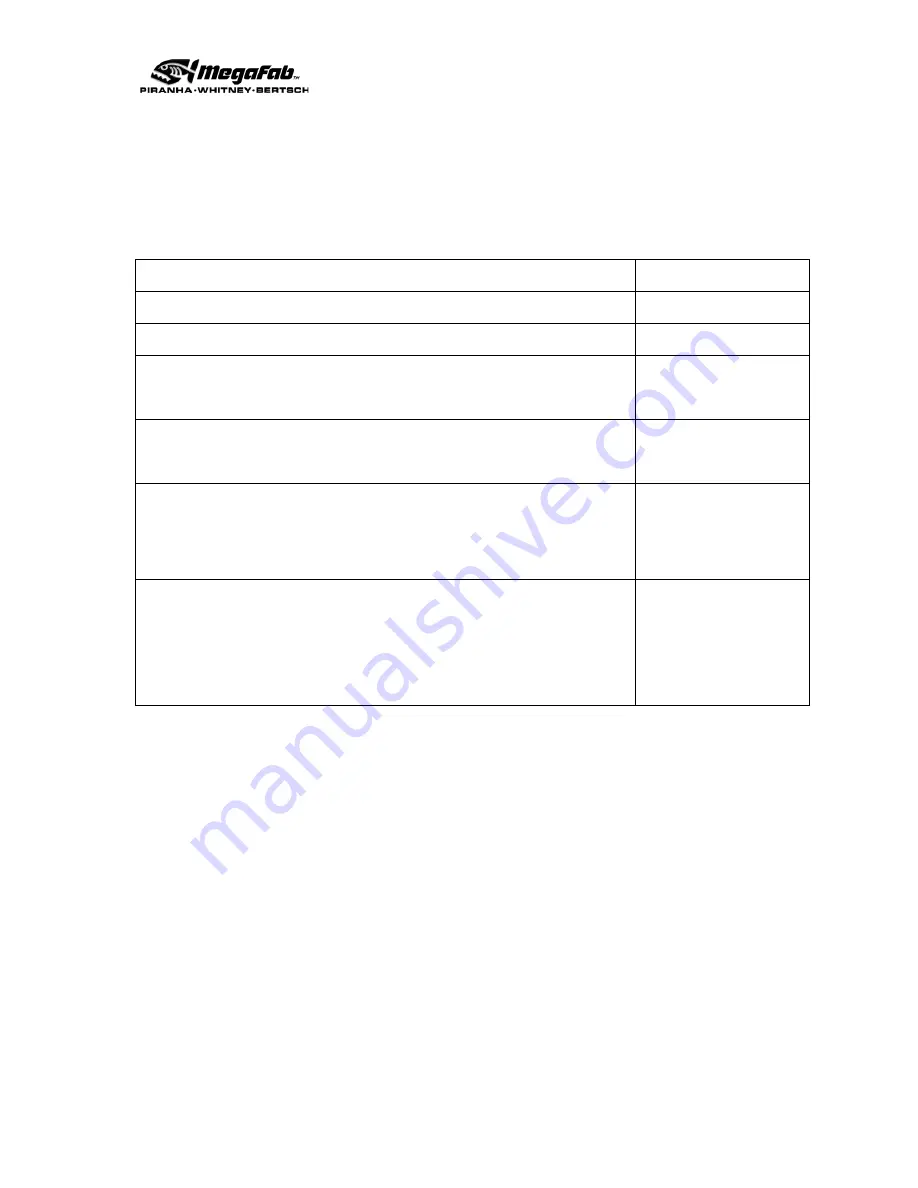

The following maintenance items should be done on a planned basis:

MAINTENANCE ITEM

FREQUENCY

Empty Slag Pan(s)

Daily

Inspect Slats and Replace where necessary

Weekly

Wipe Linear Guides X and Y Axis

•

Dry Rag; Then Apply Light Oil

Weekly

Lubricate X-Axis (1) and Y-Axis (2) Racks

•

Spray Moly Lubricant

Quarterly

Wipe Torch Height Control Guide Rods

•

Remove Yellow Cover Behind Torch

•

Dry Rag; Then Apply Light Oil

Quarterly

Lubricate X-Axis (4 total) and Y-Axis (2 Each Side) Bearings

•

Premium Grade lithium base, extreme

pressure grease such as Shell Alvania EP-

1

Annually

In addition, the operator should take care to clean the machine and surrounding

areas regularly, as needed, in order to maintain a safe work environment.

Summary of Contents for CNC Plasma Cutting Table

Page 2: ......

Page 4: ...TABLE OF CONTENTS Sept 2018 4...

Page 22: ...SAFETY Sept 2018 22...

Page 24: ...INSTALLATION Sept 2018 24...

Page 88: ...PROGRAMMING Sept 2018 88...

Page 117: ...PIPE CUTTING ATTACHMENT Sept 2018 117 Pipe Supports Pipe Cutter Base...

Page 124: ...PIPE CUTTING ATTACHMENT Sept 2018 124...

Page 128: ...PIPE CUTTING ATTACHMENT Sept 2018 128 j Then press F2 SYSTEM to see the following...

Page 136: ...PIPE CUTTING ATTACHMENT Sept 2018 136...

Page 140: ...WATER MIST CHILLER Sept 2018 140...

Page 144: ...APPENDIX A FastCAM SETUP Sept 2018 144 4 Choose the functions you need and Enter...

Page 154: ...APPENDIX A FastCAM SETUP Sept 2018 154...

Page 159: ...APPENDIX A FastCAM SETUP Sept 2018 159...

Page 164: ...APPENDIX A FastCAM SETUP Sept 2018 164...

Page 170: ...APPENDIX B Parametric Shape Library Sept 2018 170 9 Fla X 10 Lad 11 Rec 12 Rec8...

Page 172: ...APPENDIX B Parametric Shape Library Sept 2018 172 19 Rec 20 Rec c 21 Circle4 22 Rec...

Page 174: ...APPENDIX B Parametric Shape Library Sept 2018 174...