No Diving or Jumping. Observe all Safety Rules

3-3

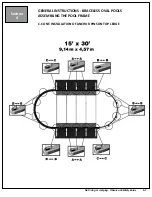

GENERAL INSTRUCTIONS - BRACELESS OVAL POOLS

ASSEMBLING THE POOL WALL

Section

3

d. To fasten the wall joint, overlap the two steel bars,

one on the inside and the other on the outside.

Tighten the mechanical screws on the inside and

the nuts on the outside. Ensure that all bolts and all

the holes are used.

(Image 7)

e. Adjusting the pool to the proper shape may cause

the bottom rails and bottom plates to slip out of

alignment a little. Recheck all of the bottom plates

to make sure each one is centred where the bottom

rails meet.

f.

Cover the seam and bolt heads on the inside/

interior of the pool wall completely with 2” (50mm)

duct tape.

(Image 8)

A. CONT. SETTING UP THE POOL WALL

7

Important Note:

Stick a screwdriver through two of the holes to help line

up the ends of the wall.

When tightening the screws start from either

the top and go down or vice versa. Do not start a

few screws from top and a few from the bottom

to meet in the middle, this can cause problems

later on.

Important Note:

The pool must be level across the perimeter. A pool that

is not level is dangerous and may collapse.

8