-

Attach the end of the delivery to the slot provided on the tank

-

Turn the ON/OFF switch to the OFF position.

Resume the oil cleaning operations after determining the cause of the

stop.

L

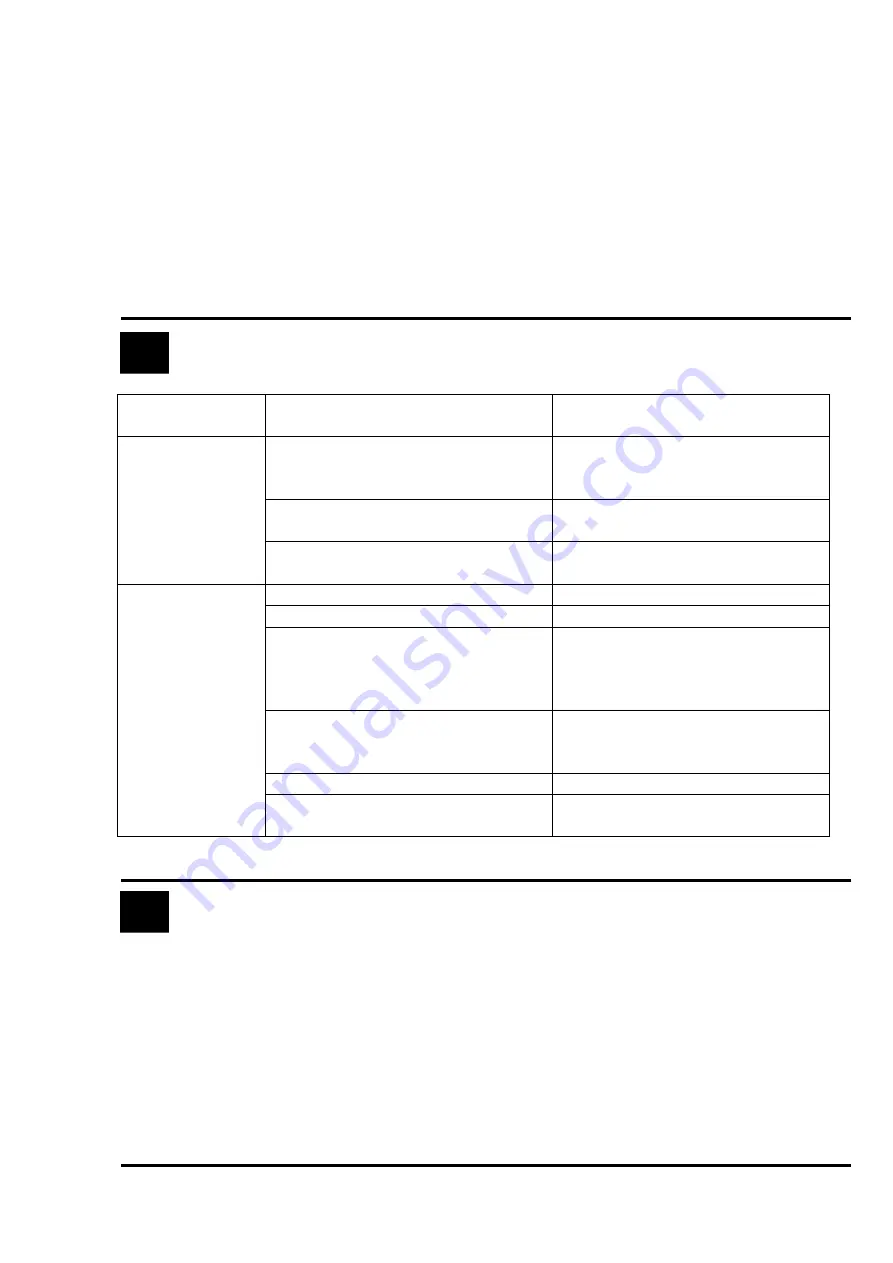

PROBLEMS AND SOLUTIONS

PROBLEM

CAUSE

SOLUTION

Lack of electric power

Check the electrical

connections and the safety

systems.

Pump rotor blocked

Dismount the pump body and

check.

Motor not

turning

Motor problems

Contact the Service

Department

Foot valve blocked

Clean or replace

Filter clogged

Replace the filter

Excessive suction pressure

Reduce the difference in

height between the

DEPUROIL and the suction

tank

Low rotation speed

Check the voltage at the

pump.

Adjust voltage if insufficient.

Fluid leaking

Check connections and seals.

Low or no

flow rate

Air entering the pump or the

suction tubing

Check connections and seals.

M

MAINTENANCE

-

Check the pump body and tubing joints on a regular basis to

promptly reveal any leaks.

-

Keep the pump body always clean to avoid wearing the rotating parts

due to the presence of undischarged solid particles.

-

During use check the pressure detected by the pressure gauge

installed on the filter cover and replace the filter when clogged.

-

Check that the electric power supply cables are in good condition.

Summary of Contents for DEPUROIL

Page 11: ...29 FILTER WITH COVER 3 4 G 1 ...