© 2016 Cop

yr

ight Pizzato Elettr

ica - tr

anslation of the or

iginal instr

uctions

9 TECHNICAL DATA

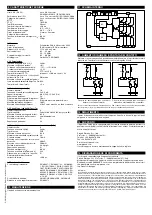

11 INTERNAL WIRING DIAGRAM

P1

P2

T02 ... T04

T01

I12

... I28

I11

A1

OS2

OS1

0V

...

A2

OS8

24V

9.1 General data

SIL level (SIL CL):

up to SIL 3 according to

EN 62061+A1:2013 / IEC 61508:2010

Performance Level (PL):

up to PL e according to EN ISO 13849-1:2008

Safety category:

up to Cat.4 according to EN ISO 13849-1:2008

MTTF

d

: 633

PFH

d

: 7.02E-09

Mission time:

20 years

Response time:

< 30 ms

Ambient temperature:

0°C ... +55°C

Storage temperature:

-20°C ... +70°C

Pollution degree:

outside 3, inside 2

Over-voltage category:

II

Rated impulse with stand voltage U

imp

: 0.8 kV

Weight:

250 g

9.2 Housing

Material:

Polyamide PA 6.6 class V0 (UL94)

Protection degree:

IP 40 (housing), IP 20 (terminal board)

Dimensions (L x H x S):

111.5 x 99.0 x 45 mm

Cross section of the conductors:

0.2 ... 2.5 mm

2

24 ... 12 AWG

Terminals driving torque:

0.5 ... 0.6 Nm

Mounting:

Din-rail 35x7.5 EN 50022

9.3 Power supply

Rated operating voltage A1-A2 U

n

:

24 Vdc

Max residual ripple in DC:

10%

Supply voltage tolerance:

- 15% ... +15% of Un

Rated power consumption (without load): < 3 W

Internal general protection:

PTC, Ih=1.5 A

Operating time of PTC:

intervention > 100 ms, reset > 3 s

Internal protection against outputs (Tx, Ox)

short circuits:

Electronic

Max outputs (Tx, Ox) currents sum:

0.5 A

Self test time at start up:

< 2 s

9.4 Inputs circuits (Ix)

Inputs number:

16

Input voltage and current:

24 V, 5 mA

Inputs signal:

0-8 V (Off), 12-24 V (On)

Galvanic insulation:

No

Min length inputs signal:

10 ms

Inputs signal filtering:

Yes, max spike length 0.4 ms

Max inputs resistance:

100

Ω

Max inputs capacity:

470 nF

toward ground and between the conductors

9.5 Testing signal circuits (Tx)

Test signal number:

4

Signal type

Pulsed 100 Hz 24V-0V, duty cycle 50%

Max current per test signal:

0.2 A

Max currents sum:

see 9.3 Power supply

Protection against short circuits

Yes

Galvanic insulation:

No

9.6 Semiconductor safety output circuits (OSx)

Output number:

8

Rated operating voltage (0V-24V):

24 Vdc

Signal type

PNP

Max current per signal:

0.4 A

Max currents sum:

3 A

Minimum current:

10 mA

Max. capacity admitted between each

output and ground:

400 nF

Max. inductance admitted per output:

500 mH

Protection fuse:

4 A type gG

Galvanic insulation:

Yes

Rated impulse with stand voltage U

imp

: 0.8 kV

Rated insulation voltage U

i

:

32 V

Short circuit detection between

safety outputs:

Yes

Test pulse length on safety outputs

< 300 µs

9.7 Conforms to the standards

Conforms to the standards:

EN 60947-1, EN 60947-5-1, EN 60204-

1, EN ISO 13849-1, EN ISO 13855, EN

1037, EN ISO 12100, EN ISO 13850, EN

60529, EN 61000-6-2, EN 61000-6-3, EN

62326-1, EN 61326-1, EN 61326-3-1, EN

60664-1, EN 62061, UL 508, CSA C22.2

n° 14-95.

Conforms to the directives:

2014/35/EU, 2006/42/EC, 2014/30/EU

Clearance and creepage distances

in accordance with:

EN 60947-1

K8

K7

K7

K8

F

-

+

Tx

Ix

24 Vdc

OS1

OS2

K8

K7

K7

K8

F

-

+

Tx

Ix

24 Vdc

OS1

OS2

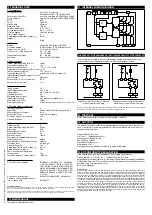

12 INCREASE OF THE NUMBER AND THE LOADING CAPACITY OF THE CONTACTS

If necessary it is possible to increase the number and the loading capacity of the

output contacts by using external contactors with forced guided contacts.

Feedback circuit for external contactors

with automatic start wiring

Feedback circuit for external contactors

with manual or monitored start wiring

For a correct system operation any safety module or PLC connected to the electronic safety outputs

OSx have to tolerate the pulse tests that are made on safety outputs .

13 DISPOSAL

At the end of service life product must be disposed of properly.

14 SUPPORT

The device has been created for safeguarding people’s physical safety, therefore in

case of any doubt concerning installation or operation methods, always contact our

technical support service:

Pizzato Elettrica Srl - Italy

Via Torino, 1 - 36063 Marostica (VI)

Tel39.0424.470.930

Fax +39.0424.470.955

E-mail tech@pizzato.com

www.pizzato.com

Our support service provides assistance in Italian and English.

15 EC CONFORMITY DECLARATION

I, the undersigned, as a representative of the following manufacturer:

Pizzato Elettrica s.r.l. , Via Torino, 1 - 36063 Marostica (VI) - Italy

hereby declare that the product is in conformity with whatever prescribed by the 2006/42/

EC Machine Directive. The complete version of the present conformity declaration is

available on our site www.pizzato.com

Mr. Pizzato Giuseppe

DISCLAIMER:

Rights to any modifications reserved without prior notice and errors excepted. The data mentioned on

this sheet are accurately checked and represent typical mass production values. All descriptions of

the device and its applications, work contexts, details on external testing, information on installation

and operation are supplied according to our best knowledge. However, this does not mean that the

characteristics described may entail legal liabilities extending beyond the “General Terms of Sale”, as

stated in the Pizzato Elettrica general catalogue. Customers/users are not exempt from the obligation

to examine our information and recommendations, as well as the relevant technical standards, before

using the products for their own purpose. Taking into account the great variety of applications and

possible connections of the device, the examples and diagrams given in the present manual are to

be considered as merely descriptive; the user is deemed responsible for checking that the specific

application of the device complies with current standards. This document is a translation of the original

instructions. In case of discrepancy between the present sheet and the original copy, the Italian version

shall prevail. The present manual may not be reproduced, in whole or in part, without the prior written

permission by Pizzato Elettrica. All rights reserved

The module is maintenance free.

10 MAINTENANCE

UL APPROVAL NOTES:

Use 60 or 75 °C copper (CU) conductor and wire size No. 30-12 AWG, stranded or solid. The terminal tightening torque

is 5 – 7 Lb-In. Supply from Remote Class 2 Source or limited voltage limited energy.

Utiliser des conducteurs en cuivre (Cu) 60 ou 75°C rigides ou flexibles de section 30-12 AWG. Couple de serrage des

bornes de 5-7 Lb In. Alimenter avec sources de classes 2 ou avec tension limitée et énergie limitée.