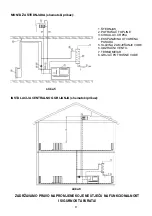

Boiler connection to the central heating system

The boiler should be connected to the central heating system with open expansion tank to

prevent the creation of excessive pressure within the system in case of water overheating

(Figure 5).

Installation of a 4-way mixer tap is recommended to achieve adequate temperature

control in the outgoing heating conduit while keeping the temperature of the water inside the

boiler at a sufficiently high level (60 – 70

°C

) to avoid creation of condensate on the boiler surface

and low-temperature corrosion. Figure 6 shows how to connect the boiler to the central heating

system. The height H should be such as to ensure sufficient pressure within the system and thus

good circulation through heating units (radiators).

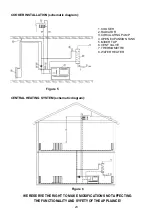

Installation of a separate boiler in the system is possible (and desirable). It should

preferably be installed so to ensure natural (gravity) circulation which is not dependent on a

pump. The boiler should be installed above the cooker level with all factors impeding water

circulation reduced to minimum (in particular, the pipes should be as short as possible, rising

towards the boiler).

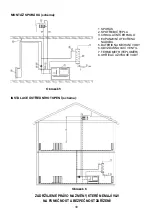

Before putting into operational use (i.e. before the first firing), make sure that the heating

system is filled with water and well deaerated. Open all locking devices. Put the circulating

pump on. Select the grate position depending on the required temperature in the central heating

system.

Operating instructions

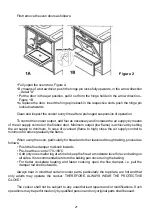

Before the first firing, wipe all enameled surfaces and cooking plate first with a wet and

then with a dry cloth. Check the air supply control and flue damper (pos.15) for proper

functioning.

The cooker performance and combustion depend on the fuel quality, adequate chimney

design, proper flame adjustment, cleanliness of the cooker and correct firing and reloading. The

cooker is designed to burn wood, wood briquettes and brown coal briquettes. Use only well-

seasoned, dry wood with low moisture content to reduce the likelihood of greasy soot (creosote)

buildup on the chimney walls, which may cause clogging of the chimney. Do not burn household

waste, especially not any plastic material. Many waste materials contain substances that are

harmful to the cooker, the chimney and the environment. For best performance, i.e. to achieve

the rated output, add two-three logs or briquettes at 30 minute intervals and set the air supply

control to the position that suits best the desired flame level.

Empty the ash pan regularly. The ash in contact with the firebox grate may cause damage

to the grate.

Start the fire with a small amount of crumpled newspaper and well-seasoned dry kindling.

Set the air supply control to fully open position and the pull the flue damper rod knob (154)

outwards. At outdoor temperatures above 15

°C

there might be some problems with the firing

due to insufficient negative draught inside the chimney (poor draught). In that case, try to

achieve sufficient negative draught by firing the chimney directly. Never use spirit, petrol or

similar flammable liquids to start the fire. Do not keep flammable liquids near the cooker.

Keep the firebox always firmly closed, except when reloading the cooker. The cooker

should be regularly cleaned and inspected by a chimney sweeper or some other qualified

person. The chimney, the flue channels and pipes should be cleaned at least 6 times a year.

Clean the cooker with maximum caution and only when completely cooled down. To clean the

cooker, remove the top plate and flue pipe first. Brush off the soot built up on the internal walls

and discharge the ash and soot with a shovel through the opening below the oven door.

20

Summary of Contents for TEPMO

Page 2: ......

Page 60: ...d o o Tisak ...