EL240.128.45 Operations Manual (020-0345-00C)

4

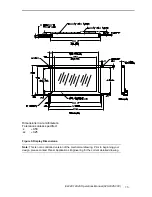

Mounting EL Displays

Properly mounted, EL displays can withstand high shock loads as well as

severe vibration found in demanding applications. However the glass

panel used in an EL display will break if subjected to bending stresses,

high impact, or excessive loads.

Stresses are often introduced when a display is mounted into a product.

Ideally, the mounting tabs of the display should be the only point of

contact with the system. Use a spacer or boss for support; failure to do so

will bend the display and cause the glass to break. The instrument

enclosure or frame should not flex or distort in such a way that during use

the bending loads might be transferred to the display. Mounting surfaces

should be flat to within ±0.6 mm (±.025"). Use all the mounting holes

provided. Failure to do so will impair the shock and vibration resistance of

the final installation.

The EL240.128.45 is a tab mounted display. Use appropriate length

standoffs to assure that screws through the mounting tabs do not

introduce bending stresses into the display. Do not deflect the ECB out of

its normal plane. The EL240.128.45 mounting tabs were designed for a 3

mm screw.

WARNING:

These products generate voltages capable of causing

personal injury (high voltage up to 230 V

ac

). Do not touch the display

electronics during operation.

Cable Length

A maximum cable length of 600 mm (24 in.) is recommended. Longer

cables may cause data transfer problems between the data transmitted

and the display input connector. Excessive cable lengths can pick up

unwanted EMI.

Cleaning

As with any glass or coated surface, care should be taken to minimize

scratching. Clean the display glass with mild, water-based detergents

only. Apply the cleaner sparingly to a soft cloth, then wipe the display.

Disposable cleaning cloths are recommended to minimize the risk of

inadvertently scratching the display with particles embedded in a re-used

cloth. Particular care should be taken when cleaning displays with anti-

glare and anti-reflective films.

Avoiding Burn-In

As with other light emitting displays, displaying fixed patterns on the

screen can cause burn-in, where luminance variations can be noticed.

Use a screen saver or image inversion to avoid causing burn-in on the

display.