Copyright Planika Sp. z o.o.

www.planikafires.com

IG0139#02

30.07.2018

27

5.9.3.

Construction of the concentric flue system

Correctly installed and configured concentric flue system by the Installer will ensure an optimized air

circulation inside the device and provide the best image of the flame.

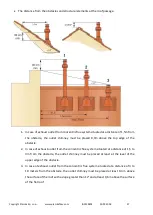

In case of output of the concentric flue system through the side wall (type C11), the following requirements

apply:

Install the system in accordance with the applicable regulations, taking into account all the difficulties

related to the wind pressure on the terminal.

Drill holes of the correct diameter in the walls/ceilings through which concentric flue system will be

passing. The remaining space should be supplemented by additional protective insulation against the

ingress of moisture into the building.

If the concentric flue system is located near the combustible walls (elements) you must ensure a

minimum distance of 100 mm from flammable materials.

Installation of the concentric flue system should always start with the one meter vertical section

(minimum height) at the outlet of the device.

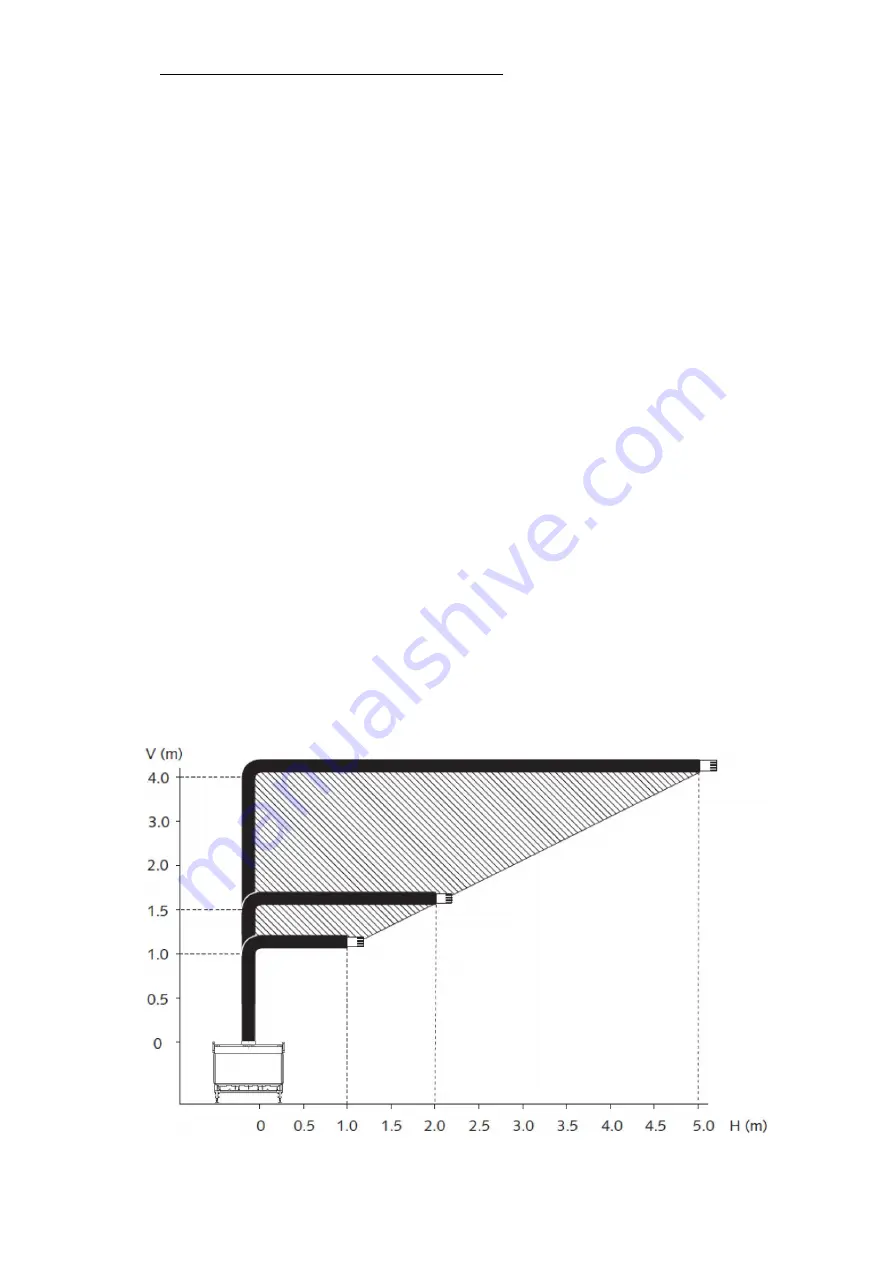

Total height of the pipe in vertical position, in case of concentric flue system getting through the wall

of the building, may not exceed a maximum length of 4 m.

Total length of the pipe in horizontal position, in case of concentric flue system getting through the

wall of the building, may not exceed a maximum length of 5 m (not including terminal).

WARNING!

For the insert using LPG, it is recommended to use up to 2 meter of horizontal section (not

including terminal).

Picture 8 – Possible system configurations with the wall terminal