4

Pos. SHARK 45

230 V

SHARK 45

115/230 V

Descrizione

Description

24

413452

413452

Cablaggio attacco centralizzato torcia Plasma

Central connection Plasma torch wiring

25

425944

425944

Elettrovalvola

Air solenoid valve

26

453249

453249

Pressostato

Pressostat switch

27

404898

404898

Basamento metallico

Steel base

28

449586

449586

Telaio interno metallico

Steel internal chassis

29

455500

455500

Raddrizzatore primario

Primary rectifier

30

435375

435375

Interruttore bipolare

1ph main switch

24

25

27

26

28

29

30

Summary of Contents for SHARK 45

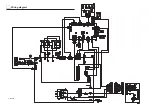

Page 10: ...10 Wiring diagram 2101EA58...