5

CONTROL PANEL (Fig. C)

Pos. 1

Cutting current adjustment knob.

Pos. 2

White LED - power supply on. When on the system

is powered and ready for use.

Pos. 3

Yellow LED with dual function and protection: THER-

MOSTAT and OVERCURRENT.

•

THERMOSTAT function:

this LED shines to indi-

cate that the overheating protection has cut in be-

cause the work cycle is not being followed. After

several minutes the overheat cut-off rearms auto-

matically (and the yellow LED turns itself off) and

the welder is ready for use again.

•

OVERCURRENT function:

this LED shines to

indi cate that the overcurrent protection has cut in

because the current has reached hazardous lev-

els. The machine stops automatically. Switch off

the machine by turning the power supply switch

(Pos. 4, Fig. B) to position “O” and switch it on

again after at least 5 seconds.

Pos. 4

GENERAL WARNING SIGNAL yellow LED. This

switches on under the following conditions:

Switched on and flashing

• External nozzle on the plasma torch missing or

screwed on incorrectly.

• Consumables (external nozzle, hood, electrode,

etc.) on the plasma torch fitted incorrectly or worn.

• In case of a faulty short-circuit on the plasma torch

between the electrode and the hood.

Switched on and steady

• No compressed air or insufficient pressure.

Pos. 5

Red PLASMA CUTTING CYCLE CHECK LED. This

LED switches on when the torch button is held down.

The plant is therefore ready for the cutting operation.

It switches off when the torch button is released.

Pos. 6

Two position control:

•

CUT -

The switch must be moved to this position

whenever you want to cut.

•

AIR CHECK -

The switch must be moved to this

position whenever you want to carry out a test to

check that air is present.

Connection of plasma torch

and ground wire

IMPORTANT:

Before performing any operation regarding con

nection of the torch and ground wire, disconnect the power to

the system.

IMPORTANT:

Do not connect to the Plasma equipment any

other torch different from the standard supplied unes; the utili

sation of other non suitable torches might be dangerous for

the operator.

Connect the plasma torch to the centralised unit as shown in

figure D, then screw the ring nut in place completely, until it is

completely closed.

To obtain elevated cutting quality, the torch must transform the

power generated by the plant into a high energy density plas-

ma jet, so that it can efficiently melt metal and guarantee suffi-

cient strength to remove the meted part from the cutting zone,

impeding the formation of burrs. The torch is this a fundamen-

tal, indispensable component of the plasma cutting plant.

The standard supplied Plasma torch has special CEA elec-

trical connections in the central adaptor. Before fitting a

new equipment, make sure that the torch central adaptor

electrical connectios are matching the ones of the Plas-

ma equipment.

Connect the earth cable to the rapid coupling on the positive

pole as indicated in figure D.

The ground wire has to be connected on the specific terminal

to the piece to be cut,

which must be effectively grounded

as well as the cutting bench

. Do not connect the ground ter-

minal to the piece of material to be removed.

WARNING:

The work area must be free of oil, paint, and rust!

1

2

3

4

5

6

FIG. C

FIG. D

Summary of Contents for SHARK 45

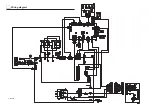

Page 10: ...10 Wiring diagram 2101EA58...