7

Maintenance

ATTENTION:

Cut off the power supply to the equipment be

fore effecting any internal inspection.

SPARE PARTS

Original spares have been specifically designed for our equip-

ment.

The use of spares that are not original may cause variations

in the performance and reduce the safety level of the equip-

ment. We are not liable for damage due to use of spare parts

that are not original.

THE EQUIPMENT

As these systems are completely static except for the fan that

is, in any case, provided with self-lubricating bushes, only the

following operations are necessary:

• Periodic removal of accumulations of dirt and dust inside the

equipment using compressed air.

• Periodical inspection for worn cables or loose connections

that could cause overheating.

• Make sure the air circuit is completely free of any impurities

and that the connections are tight and free of any leaks. In

this regard, particular attention must be given to the solenoid

valve and the air filter.

• Although the air filters do not have an automatic conden-

sate drain, it is good practice to clean the air filter insert from

time to time.

Possible problems and remedies

The power line is the cause of most problems. In case of break-

downs proceed as follows:

1) Check the line value of the voltage

2) Check that the power cable is perfectly fastened to the plug

and mains switch

3) Make sure the fuses are not burnt or loose

4) Check the following for defects:

• The switch that powers the machine

• The wall socket for the plug

• The equipment power switch

NOTE:

Given the technical knowledge required for equipment

repair, we recommend, in case of faults, that you contact quali

fied personnel or our technical support service.

TROUBLESHOOTING TABLE

It is normally possible to find the cause of a breakdown through

the 4 warning LEDS located on the right hand side of the front

of the system. The first thing to do, therefore, is to check which

leds are on. Here below we are listing some of the possible

breakdowns that may occur on the system.

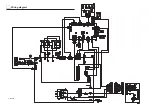

Summary of Contents for SHARK 45

Page 10: ...10 Wiring diagram 2101EA58...