INSTRUCTIONS FOR INSTALLATION AND USE.

* NOTE: For optimum installation, we recommend that you purchase an attachment kit.

1 - INSTALLATION

(the help of a second person is recommended, when mounting the bracket holder )

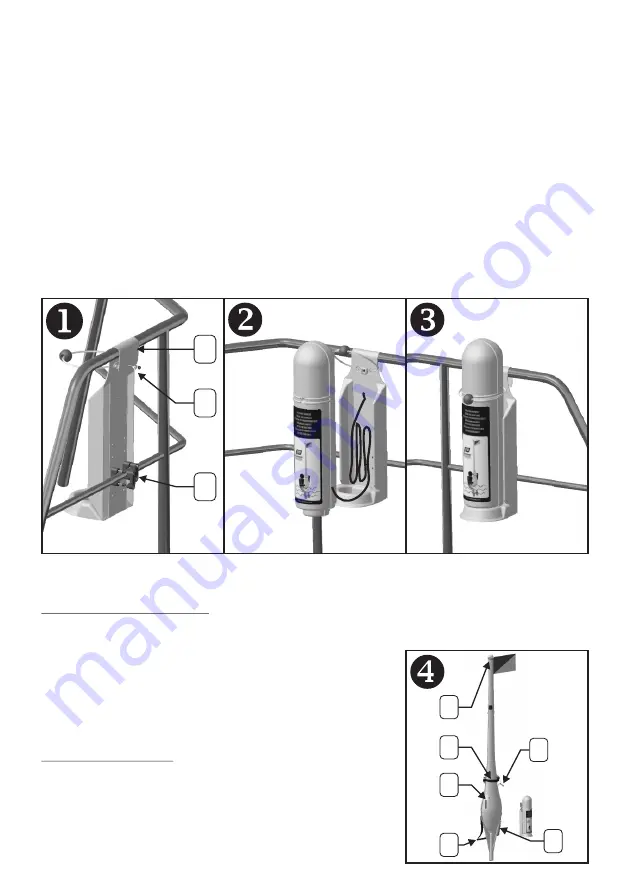

1.1 – Position the hook of the bracket holder over the top rail of the push pit (diagram 1-A)

1.2. - Remove canister from holder by pulling the blue elastic strap over the top of the canister. Make

sure the canister does not fall from the holder, as this will cause deployment. Also ensure the

lanyard between the holder and the canister is not pulled, as this will also cause deployment. A

second person may hold the canister whilst the bottom of the bracket holder is secured by means

of the two rail clamps in the fitting kit (diagram 1-B), Finally drill and fit the top rail security bolt

(diagram 1-C), Do not over tighten this bolt as this will distort and damage the holder, only tighten

to apply slight tension to the hook.

1.3 – Coil the 2m lanyard at the bottom of the holder and reinstall the canister on the holder (diagram

2)

1.4 – Replace the securing strap on the canister (diagram 3). Ensure that the firing lanyard is not

visible.

The Dan buoy is ready for use.

ENSURE SECURE FIXING OF THE BRACKET HOLDER AS THIS MAY PREVENT DEPLOYMENT IF

NOT HELD SECURE

2 - INSTRUCTIONS FOR USE.

In the event of a man overboard emergency, release the canister from the holder by pulling the blue

elastic strap over the top of the canister. (diagram 5)

Throw the canister forcefully, and complete, overboard in the

direction of the man overboard (diagram 6).

Deployment will be automatic; the lanyard with firing lever will

remain attached to the holder.

If necessary the Dan buoy may be topped up by use of the red top

up tube located on the mast.

The light on the Dan buoy is automatically activated upon inflation.

3 - CHARACTERISTICS

- flashing LED lamp 0.75cd/8h minimum (diagram 4-A)

- Co2 cylinder, 60gr (diagram 4-B)

- topping up adapter (diagram 4-C)

- whistle (diagram 4-D)

- the man overboard can hold on to the Dan buoy using the seating

strap (diagram 4-E) and the securing strap (diagram 4-F)

- 4 -

IMPRESSION PANTONE 540

SUPPORT : OFFSET 80 GRS

C

B

A

D

B

F

C

E

A

61569_01.cdr

31 mars 2014

Summary of Contents for INFLATABLE DAN BUOY

Page 2: ...ISAF ORC...

Page 3: ...3...

Page 18: ...18 TOP B A A 45cm 25cm 25cm 25cm 45cm B C D E B A C B C A B C...

Page 19: ...B 19 C B A A B A B A B From kit 63456...

Page 20: ...61569_01...