UCTION MANUAL

Page 6

4.4 Refilling the Saturator

In the event the saturator must be refilled, follow the steps outlined in the DAF Saturator

Preparation steps in section 1. Open the bleed valve to hasten the filling process.

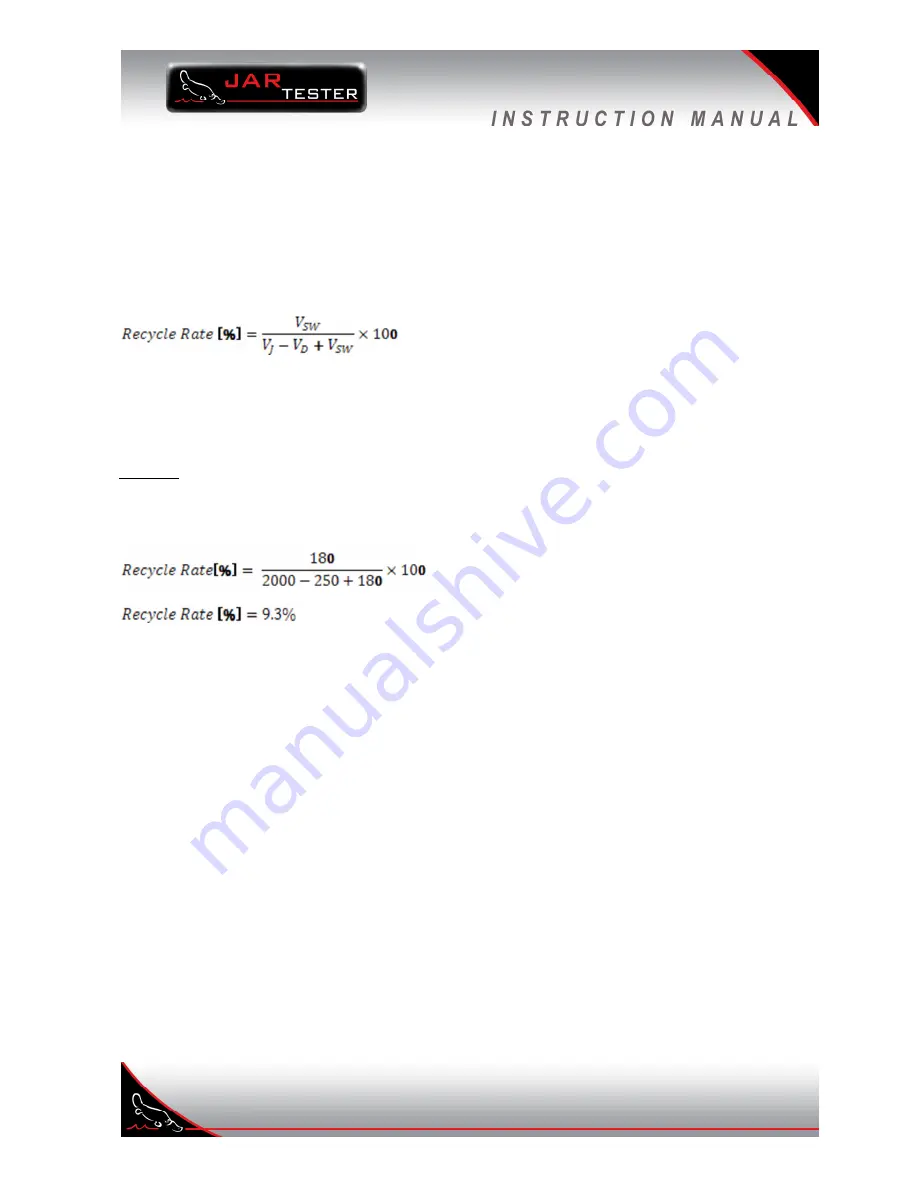

4.5 Calculating Recycle Rate

The recycle rate of the test can be calculated by utilising some of the measurements taken during

the DAF jar test.

V

SW

= Volume of saturated water transferred (per jar – this is the total volume transferred as shown

on the sight glass divided by the number of jars tested) [mL]

V

J

= Volume of test within 2L DAF Jar [mL]

this is 2000mL if filled to the line on the jar

V

D

= Volume of jar decanted

Example

Flocculation jar test performed with 2L of sample, 250mL of the sample was decanted prior to the

DAF jar test. During the DAF jar test 180mL of air saturated water was transferred.

5 PREPARING THE SATURATOR FOR STORAGE

When all testing is complete the saturator should be stored empty and depressurised. This is

achieved by the following;

1) Close the compressed air inlet valve and disconnect the compressed air line and any

connected jars.

2) Wait till the pressure gauge reads 0 kPa, if the pressure does not drop, slowly open the air

bleed valve till the pressure falls to 0 kPa.

Remove the water fill funnel cap and open the water fill valve. Invert the saturator to

completely drain it. Drying of the saturator internals by air flushing is recommended.

3) Replace the water fill funnel cap and close the water fill valve.

4) The Platypus DAF saturator is ready for storage.