www.playcraftsystems.com

For Customer Service Call

800.333.8519 (U.S.A.) or 541.955.9199 (International)

BOARDWALK CURVED 90°

INSTALLATION INSTRUCTIONS

Rev B

8/19/2019

PC-2430(1965)

Page 3 of 4

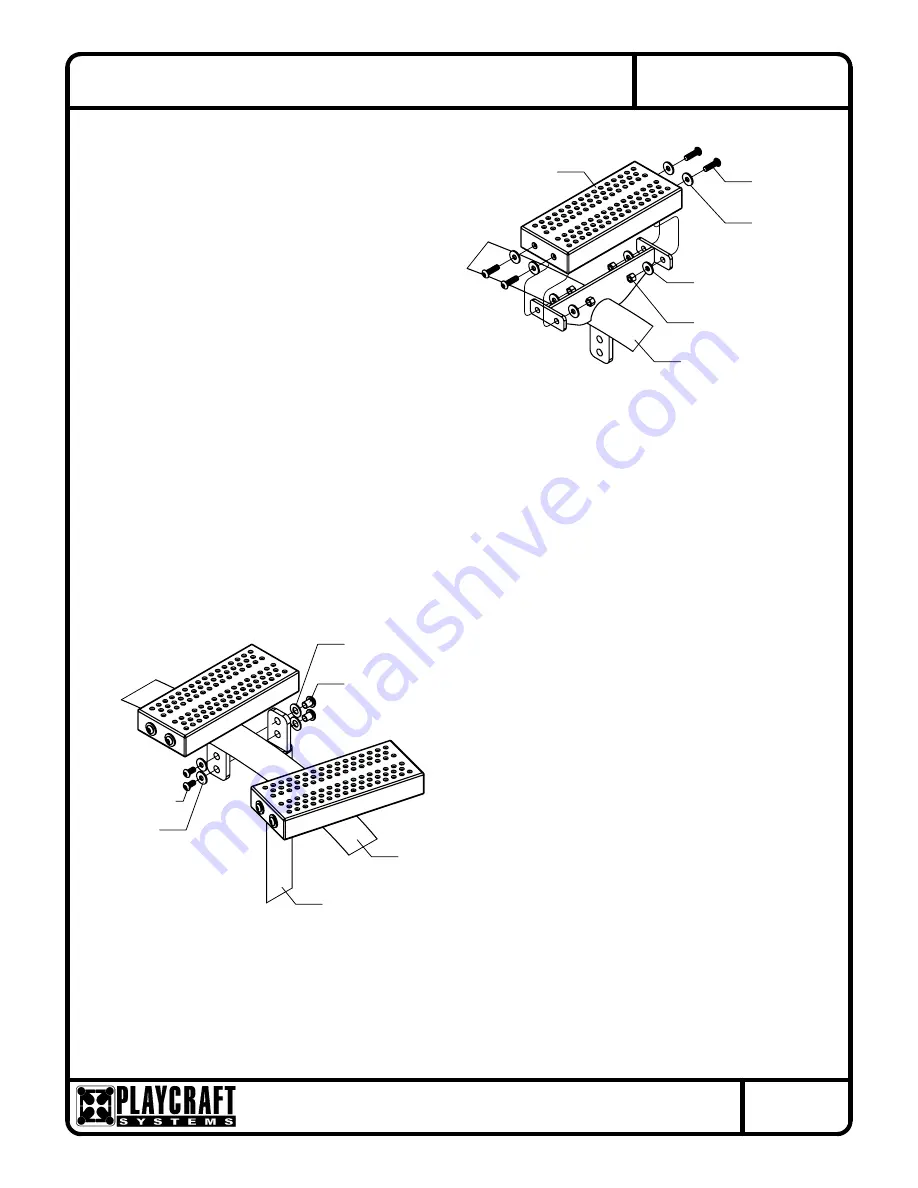

3/8" x 1-1/4"

Button Head Bolt

4 Plcs

3/8" x 1" O.D.

Washer

4 Plcs

3/8" x 1" O.D.

Washer

4 Plcs

3/8" Lock Nut

4 Plcs

Figure 1.1

BOARDWALK

CURVED 90°

WELDMENT

BOARDWALK

TREAD

3/8" x 5/8"

Barrel Nut

2 Plcs

1/2" SAE

Washer

2 Plcs

BOARDWALK

CURVED 90°

WELDMENT

BOARDWALK

LEG

3/8" x 1" O.D.

Washer

2 Plcs

3/8" x 3/4"

Button Head Bolt

2 Plcs

Figure 1.2

Step 2

(Factory Assembled)

Attach each Boardwalk Tread to Boardwalk

Curved 90° Weldment as shown in Figure 1.1.

(See Note A)

NOTE:

7 Places

Step 3

Attach Boardwalk Legs to Boardwalk Curved

90° Weldment as shown in Figure 1.2.

(See Note A)

NOTE:

3 Places

Step 4

Fully tighten all fasteners according to the

"TIGHTENING TORQUE FOR HARDWARE"

section of the Installation Manual.

Step 5

Plumb and level entire component. Pour

concrete into footing holes. Allow at least 72

hours to cure before using this equipment.

(See Note B)

Step 6

Place required protective surfacing under and

around Boardwalk Curved 90°. (See Note D)