3

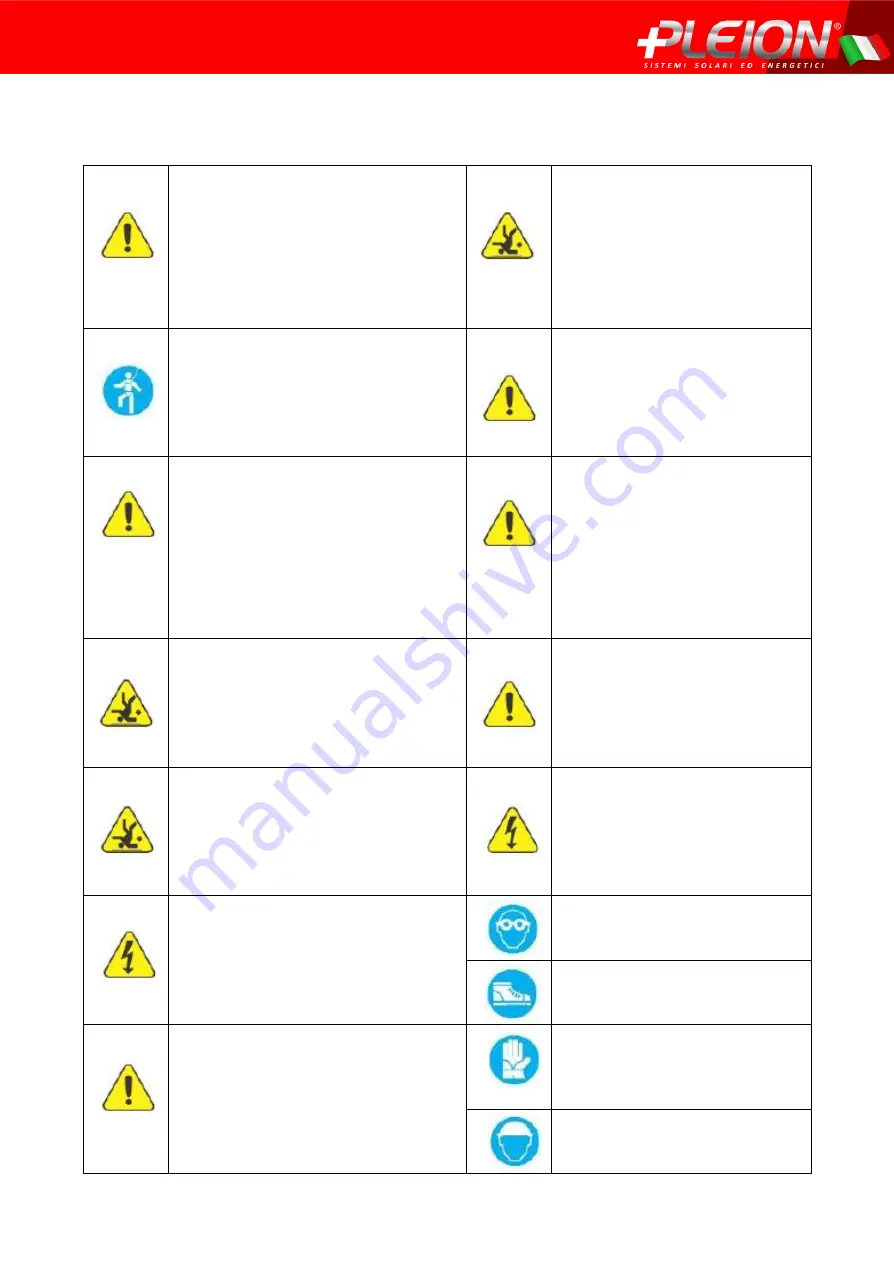

SAFETY WARNINGS

Regulation-compliant, non-personal fall

protection or safety netting or other

catch equipment, in accordance with DIN

18338 Roof Covering and Roof Sealing

Work and DIN 18451 Scaffolding Work

with Safety Net, must be installed before

starting work.

Safety harnesses must be secured

above the user if possible. Only

secure safety harnesses to building

elements or connection points with

sufficient load-bearing capacity.

If no personal fall protection or fall arrest

system or equipment has been installed

for technical reasons, safety harnesses

must be worn.

Do not use damaged ladders e.g.

splintered stringers and rungs on

wooden ladders, bent or kinked

metal ladders. Do not patch up

splintered or broken stringers, steps

and rungs of wooden ladders.

Only use safety harness equipment

(harnesses or belts, ropes and straps, fall

arresters, rope shorteners) that have

been approved by authorized testing

authorities.

Make sure that lean-to ladders are

propped securely. Apply the correct

leaning angle (68 ° - 75 °). Secure

lean-to ladders against slipping,

falling over and sinking into the

ground e.g. by using wider feet,

adjusting the ladder feet to the

ground

surface,

securing/hook

fixtures.

If no personal fall protection or fall arrest

system is used there is a risk of falling

from a great height which can lead to

serious or fatal injury if no safety harness

or equipment is used.

Only lean ladders against secure

supporting surfaces. Cordon off

ladders in traffic areas.

When using lean-to ladders, there is a risk

of dangerous falls if the ladder sinks, slips

or falls over.

Contact

with

live

overhead

electrical cables and wiring can lead

to fatal injury.

Work in the vicinity of live, electrical

cables and wiring, where contact is

possible, can only be carried out if safety

distances and precautions are observed.

Wear protective goggles when

drilling or handling collectors.

Wear safety shoes when carrying

out installation work.

The

manufacturer

declines

any

responsibility for failure to observe

safety. Regulations and/or information

contained in this manual which may

cause serious accidents/damage.

Wear cut-proof safety gloves when

carrying out installation work or

handling collectors due to sharp

edges.

Wear a safety helmet when carrying

out installation work.