45

Technical manual – Installation instructions and start-up X-RAY R - ver. 1.0 del 07/11/2018

Replacement of single tubes

Materials and equipment required: 5 mm hexagonal Allen

wrench, bucket and broom to collect residues, and replacement

tubes.

Protective equipment

When defective or damaged tubes are replaced, always wear

gloves and protective goggles.

How to recognise defective tubes

The tubes of the XRAY R collectors constantly contain a vacuum.

If a tube is damaged or is no longer hermetically sealed, due to

external circumstances, it must be replaced. A damaged tube

cannot always be recognised directly by visible broken glass.

However, a damaged tube can always be recognised by the

appearance of a whitish film, which forms with oxidation, on

the silver surface of the mirror at the foot of the tube.

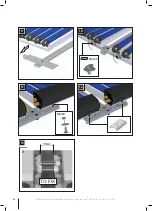

Removal of the tubes

If the tube has sustained obvious damage, carefully remove

the glass fragments without damaging the surface of the CPC

mirror. Then, using the hexagonal 5 mm Allen wrench, unscrew

the plastic support which holds the tube firm at the base of the

collector. Slide out the tube, taking care not to damage the

copper absorbers and circuit.

Installation of a single tube

Carefully check that the washer, on the head of the collector,

is still in its correct position; otherwise replace the washer in its

correct position. Slide in the vacuum tube, in the same manner

as the damaged tube was removed, taking care to correctly

align the absorbers and to avoid damaging the copper circuit.

Slide in the tubing up to the washer on the head and check that

the edges of the washer are not damaged. Screw on the plastic

support with the 5 mm hexagonal Allen wrench.

Once a year, the solar system must be checked by a specialist

firm, taking into consideration the functioning, the protection

against corrosion, the operating pressure, the preloading

pressure of the expansion tank, the thermal insulation and, if

present, the protective anode of the boiler.

Resistance of the protection against corrosion

Once a year it is necessary to check, by means of a pH

measuring stick, the protection against corrosion (the pH

value) of the anti-freeze mixture. If the pH value is less than

7, all the FAST G28 antifreeze mixture must be immediately

replaced.

Check the operating pressure of the system

Once a year the operating pressure of the system must be

checked by a specialist firm; if the pressure has decreased

and when the reason has been detected (leaks, loss from the

safety valve), it must be returned to the nominal value.

Check the pre-loading pressure of the expansion tank

Once a year, after removing the pressure from the solar side

of the tank, the pre-loading pressure of the expansion tank

must be checked.

Visual inspection of the system

During the routine annual check, the entire solar system must

be visually examined in order to detect possible damage,

leaks or excessive dirt.

Check with particular attention the state of the vacuum of the

tubes of the collector (see the paragraph “How to recognised

damaged tubes”).

Replace damaged tubes only with original spare parts

supplied by the manufacturer.

Before replacing the glass tubes, cover the collectors

concerned. In any case, make sure that the metal parts are

not particularly hot. Attention: contact with the internal

circuits can cause burns. Wear suitable protective gloves.

Air

-

bleeding

The air must be bled from the system with particular care:

•

when the system is started up

•

4 weeks after start-up

•

whenever necessary; for example, in the case of

breakdown and/or routine maintenance.

Check the thermo-vector liquid

•

Periodically (max. every 2 years) check the antifreeze

properties and the pH value of the thermo-vector liquid.

•

Check the efficiency of the anti-freeze mixture and

replace it if necessary. Normal value: -20°C

•

Check the pH value with a pH measuring instrument.

Nominal value: pH 7.5

•

Replace the thermo-vector liquid if the pH value falls

below 7.

REPAIRS

ROUTINE MAINTENANCE AND SERVICING