IP-010

Page

2

of

13

Revision 3

Be absolutely certain that the correct seal material has been selected for the intended use.

Contact PLIDCO or an authorized PLIDCO distributor if there are any questions about the seal

compatibility with the pipeline chemicals and temperatures.

The PLIDCO Clamp+Sleeve may be operated at the full design pressure in its bolted (non-welded)

state.

When repairing an active leak, extreme care must be taken to guard personnel. Severe injury or

death could result.

During the

Pipe Preparation

and

Installation

procedures, those installing the PLIDCO

Clamp+Sleeve must wear, at minimum, Z87+ safety eyewear and steel toe safety footwear.

If the pipeline has been shut down, re-pressuring should be done with extreme caution. Re-

pressuring should be accomplished slowly and steadily without surges that could vibrate the

pipeline and fitting. Industry codes and standards are a good source of information on this subject.

Do not exceed the design pressure of the PLIDCO Clamp+Sleeve. Personnel should not be

allowed near the repair until the seal has been proven.

Pipe Preparation

1.

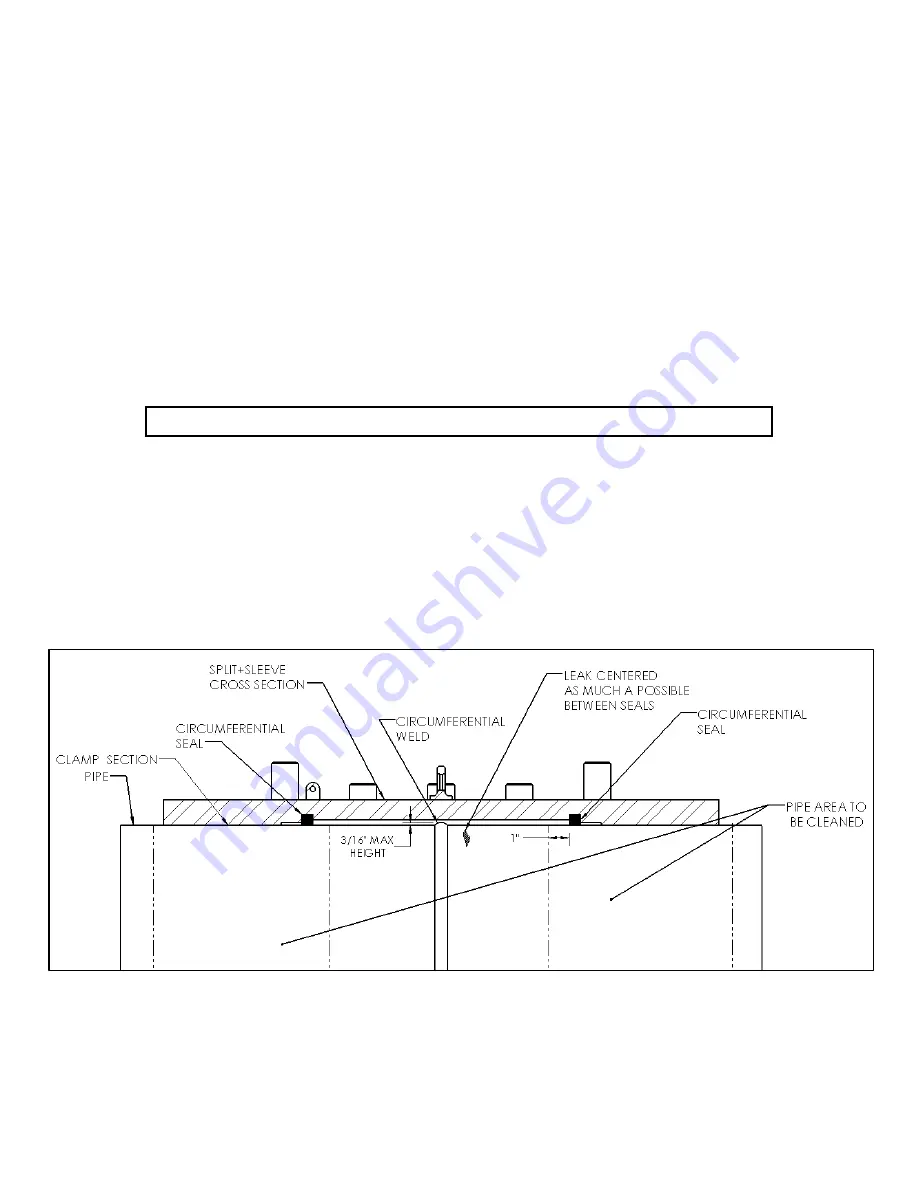

Remove all coatings, rust and scale from the pipe surface where the circumferential seals and

clamping sections of the PLIDCO Clamp+Sleeve will contact the pipe. A near-white finish, as noted

in SSPC-SP10 / NACE No.2, is preferred at location where the seals contact the pipe. The cleaner

the pipe surface, the more positive the seal.

2.

Where the circumferential seals and clamping sections will contact any pipe welds, the welds in this

vicinity must be ground flush with the outside diameter of the pipe.

3.

Circumferential pipe welds within the circumferential seals do not need to be ground flush as long

as the weld height does not exceed 3/16 inch (4.7 mm) (see Figure 1).

Figure 1

4.

The seal can tolerate minor surface irregularities up to ± 1/32 inch (0.8 mm). The defective surfaces

can be rendered suitable for sealing by applying a suitable epoxy such as Belzona 1161 and sanding

or filing the surface to match the required outer diameter.

Note: Epoxy may only be applied to the area where the seals will land. It is not intended to rebuild

the pipe wall to the nominal OD or to repair large sections of exterior corrosion.