IP-010

Page

3

of

13

Revision 3

5.

A PLIDCO Clamp+Sleeve is capable of sealing on out-of-round pipe up to approximately 5% ovality.

This is based on the ability of the bolting to reshape the pipe. For very thick wall pipe the bolting

may not be able to reshape the pipe. Badly out-of-round pipe may require a different length PLIDCO

Clamp+Sleeve to ensure the circumferential seal are positioned on round pipe.

6.

A PLIDCO Clamp+Sleeve is not capable of reshaping flattened or dented pipe.

Lifting & Handling

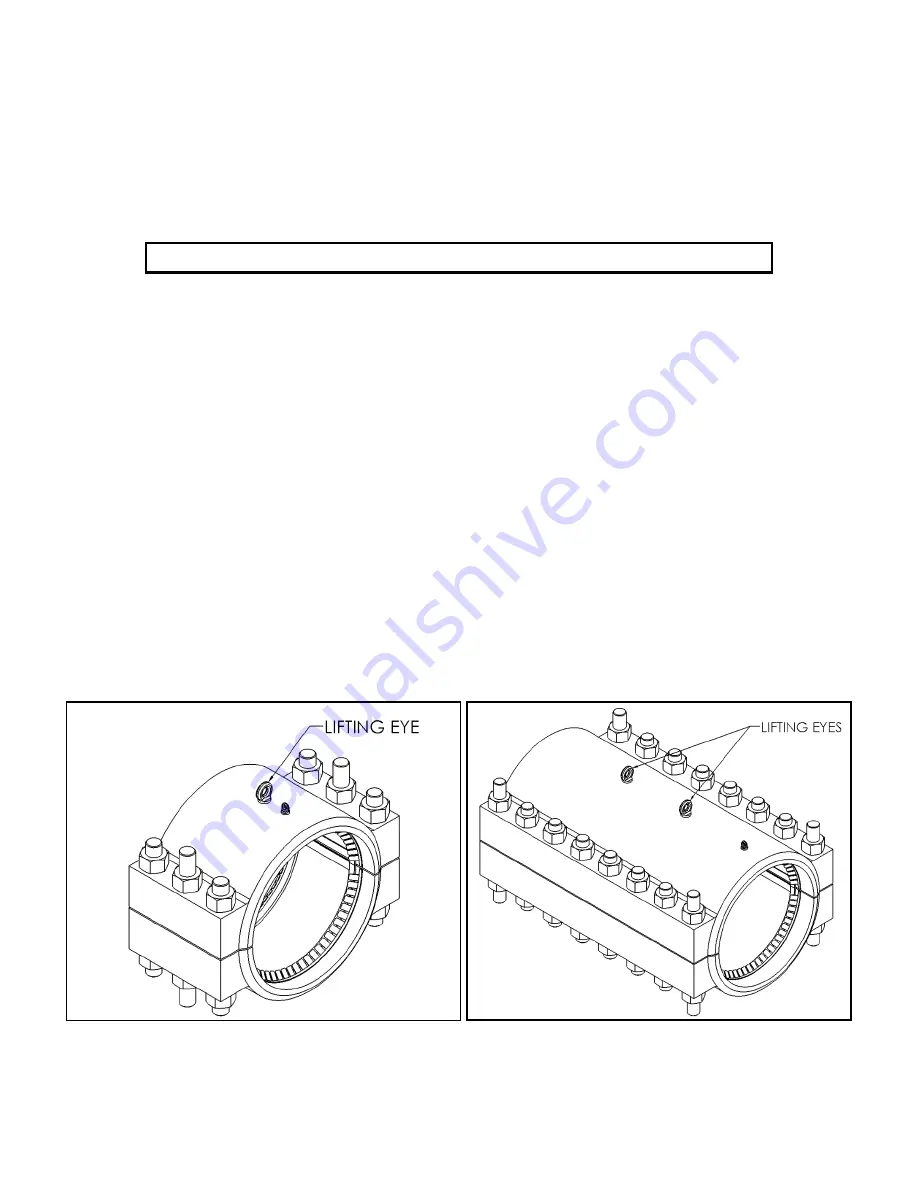

When not being moved or transported on a pallet, PLIDCO Clamp+Sleeves should always be lifted,

transported, or installed using the installed lifting eyes as shown in Figures 2 & 3. All Clamp+Sleeves

that exceed 50 lbs. per half or are too heavy to move and install by hand are provided with lifting eyes

on each half. Longer fittings are provided with two lifting eyes as shown in Figure 3. If two lifting eyes

per half are provided, both lifting eyes are required to lift the fitting. Chains, hooks, shackles, or straps

suitable for the weight of the fitting(s) shall be used, and must be securely inserted through the lifting

eyes.

The lifting eyes are designed to support the weight of a fully assembled Clamp+Sleeve. The lifting eyes

are installed on both halves of the fitting, and should be used to maneuver or lower Clamp+Sleeve onto

the pipeline.

Vertical installations or installations that require special rigging due to space, obstructions, or location

may require additional lifting eyes to be added in locations other than shown in Figures 2 & 3. These

can be added prior to ordering or sent back to a PLIDCO manufacturing facility to be added by PLIDCO

personnel.

Note: Careless handling can damage the seals and GirderRings (seal retainers). Lifting devices such as

chains, cables, or straps should never contact the seals or GirderRings. Never lift the fitting by

inserting the forks from a fork lift inside of the fitting. Contact on the seals or GirderRings can result

in the seals being pulled from their grooves. (See Figure 4)

Figure 2 Figure 3