Summary of Contents for 501

Page 1: ...Tilt Table Model 501 SERVICE MANUAL ...

Page 6: ...Tilt Table Service Manual 6 P a g e ...

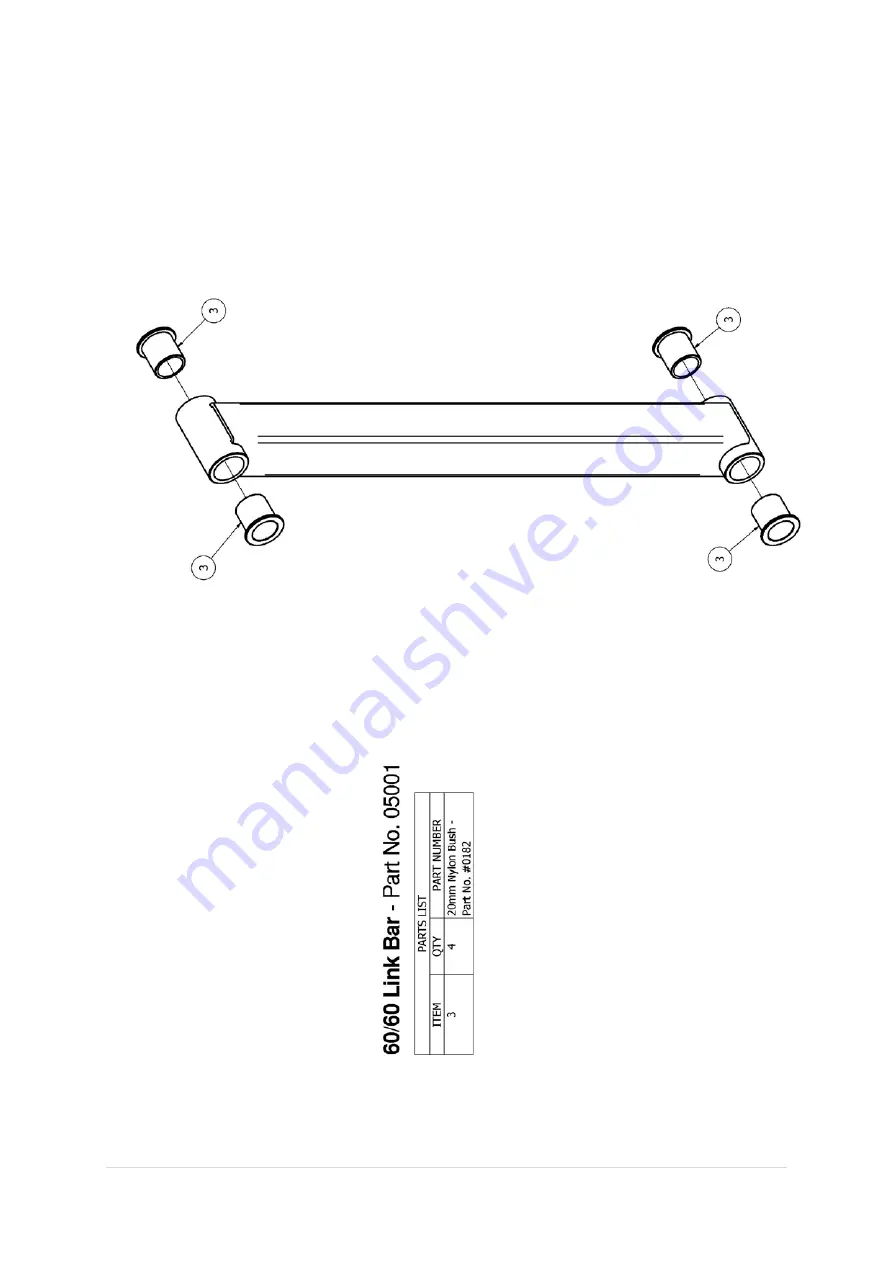

Page 8: ...Tilt Table Service Manual 8 P a g e 5 Parts lists and diagrams ...

Page 9: ...Tilt Table Service Manual 9 P a g e ...

Page 10: ...Tilt Table Service Manual 10 P a g e ...

Page 11: ...Tilt Table Service Manual 11 P a g e ...

Page 12: ...Tilt Table Service Manual 12 P a g e ...

Page 13: ...Tilt Table Service Manual 13 P a g e ...

Page 14: ...Tilt Table Service Manual 14 P a g e ...