1

25

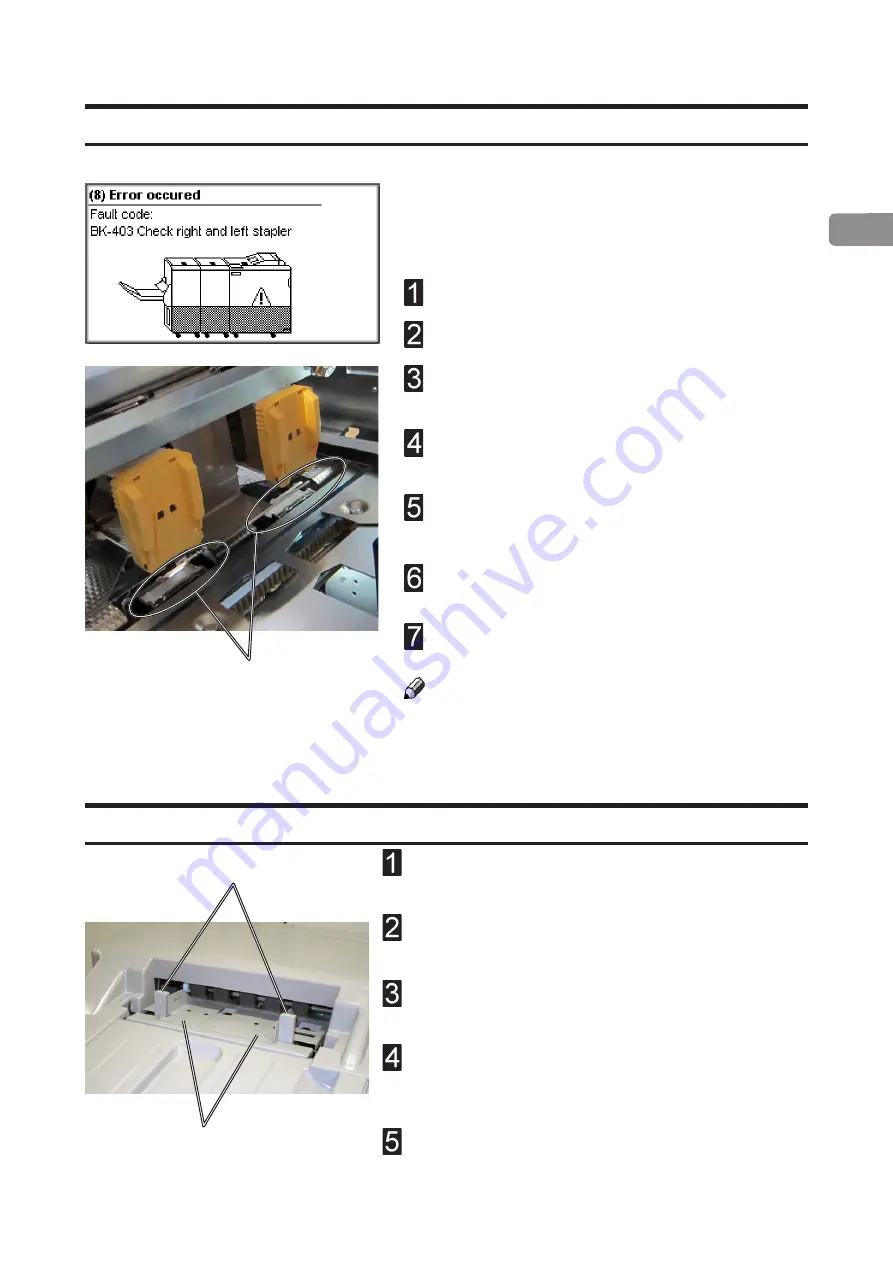

If the booklet maker indicates “Check left/right/left

and right stapler”, it means that there is a jam in

the indicated stapler. Remove the stapler cartridge

as described above.

Open the booklet maker top cover.

Pull out the staple cartridge.

Remove any sheets left in the booklet maker

and look for jammed staples stuck in the sheets.

Look inside the staple cartridge for jammed

staples and remove them if any.

Look at the clinchers (A) and remove any

jammed staples.

Push the staple cartridge into stapler until it

snaps in position.

Close booklet maker top cover and restart the job.

Note

If the error message persists for no reason or if

staple jam reoccurs, renew the staple cartridge as

described above.

Check left/right stapler

Loading covers

[A]

Make sure that the cover sheets are well fanned to

avoid misfeeds or double-feeds.

Align the cover sheets well to achieve a reliable

feeding operation and good finishing results.

Make sure that the ink has completely dried, to

avoid smearing.

Press on top of either air nozzle (A) to lower the

paper bin. Load the covers facing downwards into

the paper bin.

Move the adjustable side guides (B) up against the

cover sheets until there is no clearance.

Cover feeder

B

A

Summary of Contents for BK5030

Page 6: ...Page intentionally blank ...

Page 50: ...6 50 Page intentionally blank ...

Page 62: ...Page intentionally blank ...

Page 64: ......