Product Specifications

Plockmatic PowerSquare™ 160 - Service Training Workbook

55

14.

Product Specifications

Watkiss PowerSquare™ 160

February 2018

Operating

Conditions

10-35°C at 35-85% relative humidity, up to 3000m amsl

Production

Cycle time: Printer dependent

Minimum interset gap: 3 seconds

Minimum set time: 6 seconds

Typical set time: depending on job settings

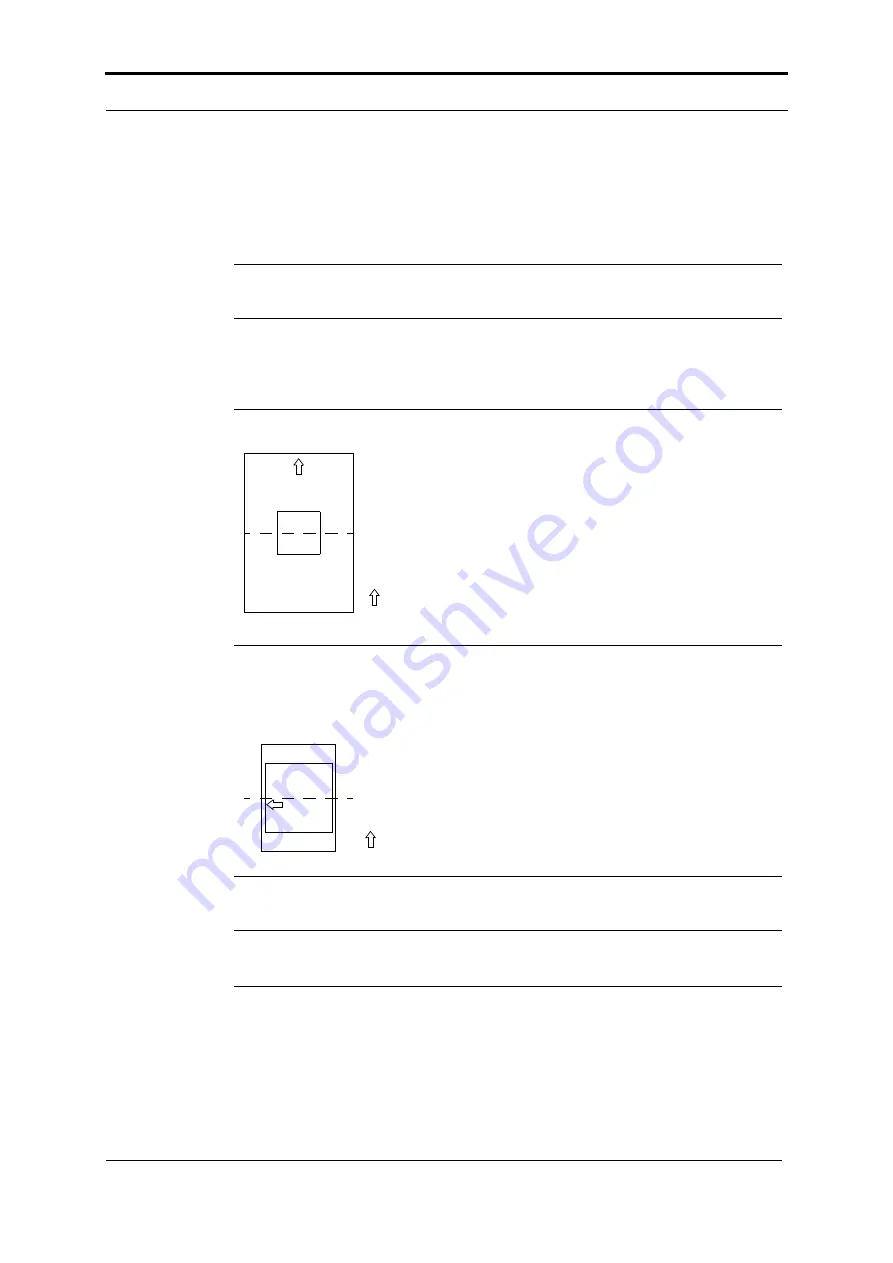

Stock Sizes

Minimum input size: 200x200mm for online 140x200mm for hand feed version

Maximum input size: 370 x 620mm

Sheet Rotation

Sheet rotation module ensures maximum printer productivity.

Maximum rotation sheet size: 353 x 252mm

Minimum rotation sheet size: 215 x 200mm

The cross-track dimension of the sheet (before rotation) must be at least 7mm

greater than the in-track dimension.

Sheet Feed

Orientation

Cover first, face up

Stock Range

60 - 400gsm dependent on paper type and quality

Coated paper minimum 90gsm

Set Thickness

Minimum set thickness: 1 sheet (when folded makes a 4 page leaflet). (Fold

accuracy may be reduced if no staples are present)

Maximum set thickness: 4mm, dependent on material.

80gsm bond paper

Maximum set thickness: 4mm (approx 40 sheets 80gsm)

Machine coated papers

Maximum set thickness 3mm, dependent on material

200 x 200mm

370 x 620mm

Staple & fold line

indicates original lead edge

from the printer

Staple & fold line

indicates original lead edge

from the printer

200mm

353x 252mm

215mm

Summary of Contents for Morgana PowerSquare 160

Page 72: ...Glossary of booklet making terms 68 Plockmatic PowerSquare 160 Service Training Workbook...

Page 73: ......

Page 74: ......

Page 75: ......