Description of Operation

Plockmatic PowerSquare™ 160 - Service Training Workbook

9

3.

Description of Operation

After the PSQ160 is turned on, the operator either enters the paper size and

direction on the GUI or loads a previously saved job. Set thickness is handled

automatically by the PSQ160. When the job is gathered in the PSQ160, each sheet

is flipped upside down by the infeed drum, therefore the job must be printed ‘first-to-

last, face up’. See

to

The PSQ160 is controlled by the printer and by a system of internal sensors.

3.1

Paper Enters the System

• When the print job starts, the printer sends a cycle-up signal to the PSQ160.

• Paper leaves the printer and enters the rotator module in the connecting bridge.

The paper is moved through the connecting bridge by belts into the gathering

area.

• Paper can be accepted from either ‘side-referenced’ or ‘centre-referenced’

printers. The connecting bridge translates the paper to ‘centre-referenced’ for the

PSQ160.

• When the page is in A4 portrait format, the paper can be rotated through 90° by

the turning-ball in the connecting bridge if necessary.

• A3 (17 x 11") and A4 (11 x 8½") landscape jobs move through the bridge without

rotation. The turning-ball is not in the paper path. The conveyor drive belt is at a

small angle to the sidelay and drives the paper against the sidelay.

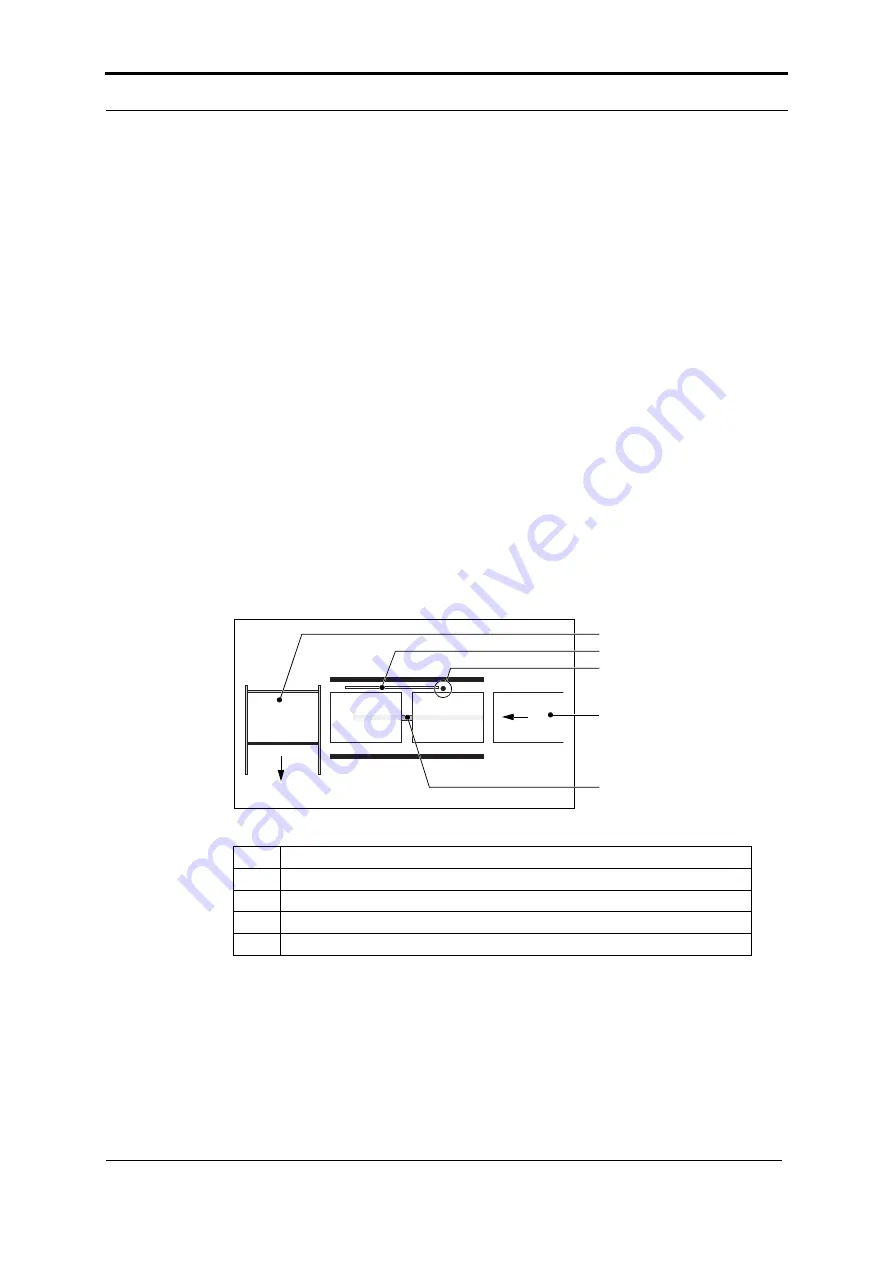

Figure 5. A3 (11 x 17") paper moves straight through the connecting bridge

• A4 (8½ x 11") portrait jobs are rotated around the turning-ball. The paper is

driven against the sidelay by the angled, bridge drive-belt. The sidelay makes

sure the paper aligns to the centre reference line of the bridge.

A

Gathering Area

B

Sidelay

C

Turning-ball

D

A3 paper leaves the printer

E

Bridge Drive Belt

A

B

C

D

E

Summary of Contents for Morgana PowerSquare 160

Page 72: ...Glossary of booklet making terms 68 Plockmatic PowerSquare 160 Service Training Workbook...

Page 73: ......

Page 74: ......

Page 75: ......