6

Copyright © Roy Gripske & Sons Pty. Ltd. 2012

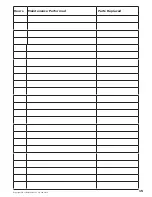

Adjusting Cutting Depth

• Move control lever over to the

right to raise or lower cutting

blade assembly.

A. Control Lever

• When control lever is moved

back to center position, pin

locates in appropriate hole for

required cutting depth.

A. Pin

Adjusting Curb Height

• Move control lever over to the

left and lift up on right-hand

handle to change curb height

setting.

• When control lever is moved

back to center position, pin

locates in appropriate hole for

required curb height setting.

A. Pin

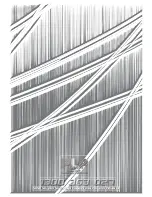

Adjusting Blade Angle

Adjust blade angle

BEFORE engaging

blade. Do not make

adjustments when blade

is rotating.

Vertical blade angle

• Move blade angle lever to

middle segmented position.

Right-vertical and left-vertical

blade angle

• Lift blade angle lever and

move to right or left of center

segmented position.

A. Blade Angle lever

Fuel

Use only clean fresh unleaded

regular grade gasoline

Gasoline is extremely

fl ammable and can be

explosive under certain

conditions. Turn the

engine switch OFF.

Do not smoke. Make

sure the area is well

ventilated and free from

any source of fl ame or

sparks; this includes any

appliance with a pilot

light. Never fi ll the tank

so the fuel level rises

into the fi ller neck. If

the tank is overfi lled.

heat may cause the fuel

to expand and overfl ow

through the vents in the

tank cap. After refueling,

make sure the tank cap

is closed securely. If

gasoline is spilled on

the fuel tank, wipe it off

immediately.

Fuel Tank Capacity

Capacity 1.8 L

Engine Oil

The following engine oils are

recommended:

API Service Classifi cation SF, SG,

SH or SJ

ALL SEASONS: Use SAE 1 OW-30

oil.

Adjust cutting depth

BEFORE engaging blade.

CAUTION

A

A

A

OPERATION

WARNING

A

WARNING

A

A. Control Lever