10

10.4 Monthly Inspections

Service &

Maintenance

10

10.4 Monthly Inspections

SERVICE &

MAINTENANCE

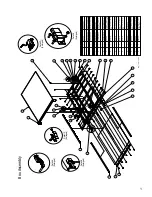

Regular lift maintenance is recommended at MONTHLY intervals by the lift operating

company. The working life of your lift will be greatly prolonged if these steps are adhered

to.

This should include the following:

1. Check for obvious signs of damage, replace parts as necessary.

2. Check the operation and stowing of the lift, if the platform base is touching the

bottom of the box, adjust tow height by raising the N/S and O/S stowing bolts.

3. Check the box lock operation by attempting to pull the lift out of the box with the

lock engaged. If this can be achieved, the hook will need to be LOWERED in

relation to the handle.

4. Check the carriage lock operation by attempting to push the lift back into the box

once the platform has been fully deployed. If this can be achieved the carriage lock

mechanism will require adjustment.

5. Check the rear roll-off-ramp operation. Check ramp ‘dummy pin’ which holds ramp

in vertical position whilst lift is stowed. Lubricate roll-off pivot with silicone spray in

accordance with instructions on 10.6.

6. Check bridging plate operates correctly, it must land flat on the vehicle floor, if not

see Bridge plate adjustment instructions 7.7.

7. Check platform extension operation and security of alloy sheet. N.B. do not over-

tighten fastenings which hold extension alloy. Check platform end stops are tight

and vertically aligned.

8. Check hand rail operation and security. If components are corroded they should be

replaced due to potential hazard to users! Check location pivot pins, these should

be fully secure.

9. When cleaning the vehicle wash the working platform of the lift in accordance with

instructions on 9.1.

10. Check Up/ Down pump for fluid leaks and loose/ corroded electrics. Top up

reservoir (with lift at ground position) with PLS Blue Hydraulic Oil, do NOT overfill.

Coat any exposed electrics with dielectric grease (or similar) to protect.

11. Lubricate lift in accordance with instructions on 10.6.

IF IN DOUBT, CONTACT THE MANUFACTURER

Summary of Contents for Access ACC-1150

Page 7: ...1 1 5 Heath Safety Scooters General ...

Page 23: ...7 7 7 Floor Height Adjustment Installation 7 INSTALLATION 7 6 Floor Height Adjustment ...

Page 25: ...7 7 9 Weight Test Installation 7 INSTALLATION 7 8 Weight Test Dynamic Dynamic ...

Page 30: ...Thread Size Tightening Torque Nm Hydraulic Fitting BSP 1 8 17 0 1 4 34 0 3 8 47 0 ...

Page 31: ...8 8 1 Standard Operating Procedure Operation 8 OPERATION 8 1 Standard Operating Procedure ...

Page 32: ...8 8 2 Manual Override Procedure Operation 8 OPERATION 8 2 Manual Override Procedure ...

Page 35: ...10 10 2 Loler Service Maintenance ...

Page 44: ...13 13 1 Wiring Diagram Power Pack Diagrams 13 DIAGRAMS 13 1 Wiring Diagram Power Pack ...

Page 46: ...13 13 3 Hydraulic Diagram Diagrams 13 DIAGRAMS 13 3 Hydraulic Diagram ...

Page 82: ...15 Notes ...

Page 83: ...15 Notes ...