6

Logistics

HANDLING STAFF MUST WEAR: SAFETY SHOES WITH STEEL

TOE CAP AND NON-SLIP SOLES.

MAKE SURE THAT NO UNAUTHORISED PERSONS ARE

STANDING WITHIN THE RADIUS OF ACTION OF THE

LIFTING/HANDLING MEANS (FORK LIFT TRUCK,

TRANSPALLET, ETC.) DURING THE LIFTING, TRANSPORT AND

HANDLING OPERATIONS.

Procedures for packaging removal are explained below:

•

Using a Stanley Knife with a maximum blade length of 10mm, cut along the 4 sides of the

base of the packaging, remove tape and ensure waste cardboard is recycled

•

For wooden crates, remove nails from top panel and those present on the side walls

.

STAFF REMOVING THE PACKAGING MUST WEAR:

SAFETY SHOES WITH STEEL TOE CAP AND NON-SLIP SOLES

AND GLOVES.

6.3 Handing

6

LOGISTICS

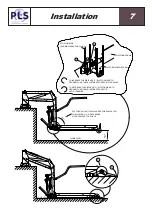

All lifting and short workshop distance

transportation of packages lifts must be carried

out using a forklift truck.

Safe lifting can only be achieved when using

suitably rated load capacity equipment (Please

refer to Technical Data Table for indicated lift

weight)

6.3 Handling Access™ EA & Access™ EAB

HANDLING STAFF MUST WEAR: SAFETY SHOES WITH STEEL

TOE CAP AND NON-SLIP SOLES.

MAKE SURE THAT NO UNAUTHORISED PERSONS ARE

STANDING WITHIN THE RADIUS OF ACTION OF THE

LIFTING/HANDLING MEANS (FORK LIFT TRUCK,

TRANSPALLET, ETC.) DURING THE LIFTING, TRANSPORT AND

HANDLING OPERATIONS.

Procedures for packaging removal are explained below:

•

Using a Stanley Knife with a maximum blade length of 10mm, cut along the 4 sides of the

base of the packaging, remove tape and ensure waste cardboard is recycled

•

For wooden crates, remove nails from top panel and those present on the side walls

.

STAFF REMOVING THE PACKAGING MUST WEAR:

SAFETY SHOES WITH STEEL TOE CAP AND NON-SLIP SOLES

AND GLOVES.

6.3 Handing

6

LOGISTICS

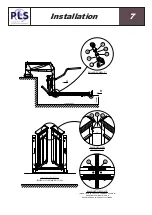

All lifting and short workshop distance

transportation of packages lifts must be carried

out using a forklift truck.

Safe lifting can only be achieved when using

suitably rated load capacity equipment (Please

refer to Technical Data Table for indicated lift

weight)

Logistics

6

6.3 Handling Access™ EA & Access™ EAB

HANDLING STAFF MUST WEAR: SAFETY SHOES WITH STEEL

TOE CAP AND NON-SLIP SOLES.

MAKE SURE THAT NO UNAUTHORISED PERSONS ARE

STANDING WITHIN THE RADIUS OF ACTION OF THE

LIFTING/HANDLING MEANS (FORK LIFT TRUCK,

TRANSPALLET, ETC.) DURING THE LIFTING, TRANSPORT AND

HANDLING OPERATIONS.

Procedures for packaging removal are explained below:

•

Using a Stanley Knife with a maximum blade length of 10mm, cut along the 4

sides of the base of the packaging, remove tape and ensure waste cardboard is

recycled

For wooden crates, remove nails from top panel and those present on the side walls

.

STAFF REMOVING THE PACKAGING MUST WEAR:

SAFETY SHOES WITH STEEL TOE CAP AND NON-SLIP

SOLES, GLOVES AND SAFETY GLASSES.

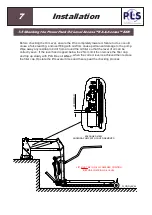

All lifting and short workshop distance

transportation of packages lifts must be carried

out using a forklift truck.

Safe lifting can only be achieved when using

suitably rated load capacity equipment (Please

refer to Technical Data Table for indicated lift

weight)

IF THE DELIVERED DEVICE DOES NOT COMPLY WITH THESE

REQUIREMENTS, NOTIFY THE MANUFACTURER IMMEDIATELY.

STORAGE OF THE LIFT IN CONDITIONS THAT DO NOT

COMPLY WITH THE ABOVE DESCRIPTION SHALL NULLIFY

THE WARRANTY FOR ANY PARTS TO BE REPLACED.

store

Note: If a lift is to be dry stored for more than 12 months then all cylinder seals MUST be

checked before operation

6

LOGISTICS

6.1 Receipt and Inspection

Upon delivery of the lift, you need to perform the following inspections:

- Ensure the product delivered corresponds to the relevant documentation e.g. the order

specification and the transport document.

- Examine packaging to ensure it is undamaged and all parts are intact during

transportation.

- With great care, examine all devices to ensure they haven’t been damaged during

transportation and all parts haven’t been tampered or removed.

- Ensure all documentation required for installation has been supplied.

6.2 Storing The Lift

If the lift is not used, proceed as follows:

-

Transport lift to an appropriate storage area, free from atmospheric agents /

elements.

-

Ensure all electrical / electronic devices are insulated from external environment so

to prevent humidity damaging those components.

-

Storage area selected MUST ensure temperature variation is between 5°C to 50°C

fresh hold.

-

Ensure all sliding parts (guides, cylinders ...) are adequately protected from dust,

rust and water damage.

-

Do not store for over 6 months. For longer periods of storage, before putting into

service contact the manufacture to have the lift conditions inspected.

IF THE DELIVERED DEVICE DOES NOT COMPLY WITH THESE

REQUIREMENTS, NOTIFY THE MANUFACTURER IMMEDIATELY.

STORAGE OF THE LIFT IN CONDITIONS THAT DO NOT

COMPLY WITH THE ABOVE DESCRIPTION SHALL NULLIFY

THE WARRANTY FOR ANY PARTS TO BE REPLACED.

store

Note: If a lift is to be dry stored for more than 12 months then all cylinder seals MUST be

checked before operation

6

LOGISTICS

6.1 Receipt and Inspection

Upon delivery of the lift, you need to perform the following inspections:

- Ensure the product delivered corresponds to the relevant documentation e.g. the order

specification and the transport document.

- Examine packaging to ensure it is undamaged and all parts are intact during

transportation.

- With great care, examine all devices to ensure they haven’t been damaged during

transportation and all parts haven’t been tampered or removed.

- Ensure all documentation required for installation has been supplied.

6.2 Storing The Lift

If the lift is not used, proceed as follows:

-

Transport lift to an appropriate storage area, free from atmospheric agents /

elements.

-

Ensure all electrical / electronic devices are insulated from external environment so

to prevent humidity damaging those components.

-

Storage area selected MUST ensure temperature variation is between 5°C to 50°C

fresh hold.

-

Ensure all sliding parts (guides, cylinders ...) are adequately protected from dust,

rust and water damage.

-

Do not store for over 6 months. For longer periods of storage, before putting into

service contact the manufacture to have the lift conditions inspected.