Automist Smartscan

®

Handbook v1.2.3

Plumis Ltd Copyright © 2017. All Rights Reserved.

Page 27 of 64

S MA RT SC AN

®

Automist Smartscan Known Heat Source Mitigation Procedure

Object Type

Positional Constraints

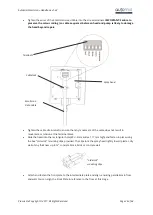

Radiator or heated towel rail, within 180° field of

view of spray head, with height less than 800mm

No constraints.

Radiator or heated towel rail, within 180° field of

view of spray head, with height above 800mm

No point on the radiator must be closer than 3.0m

from any spray head. Spray heads may be

permitted to be closer to the radiator when

mounted on the same flat wall as the radiator, but

still no closer than 1.0m.

Real fire, gas fire, or electric heater with exposed

heating elements

No spray head should be mounted in a position

whereby the flames or heating elements are in view

of the spray head, at any distance. Walls of any

visibly opaque construction can be regarded as

blocking this view.

Cooker hob or oven

Spray heads must be located at least 2.5m distant

from any cooker hob or oven that is in view of the

spray head’s sensor.

The spray head can be

installed in the same wall as the hob or oven 2m

away.

Table 2: Known heat source mitigation procedure