Automist Smartscan

®

Handbook v1.2.3

Plumis Ltd Copyright © 2017. All Rights Reserved.

Page 39 of 64

S MA RT SC AN

®

hoses with a robust rubberised exterior and double wire braiding are recommended such as DIN EN 853

2SN / SAE 100R2AT or DIN EN 857 2SN, rated to 400 bar working pressure and a minimum internal

diameter of 6.3mm. Hoses crimped on-site must be pressure tested to at least 150 bar before the

commissioning procedure to check for correct assembly. High pressure hoses left exposed in the protected

volume, particularly at height, could be compromised in a fire. Hoses should therefore be encased in the

wall whenever possible. Where possible, hoses should be run low in the room, all other factors being equal,

and in any case the locations of hoses must be chosen so that they will not be exposed to temperatures

above 100°C. For hoses longer than 10m and up to 20m, please refer to the high pressure hose technical

specification document on the Partner Site. Longer hoses require an increased internal diameter of 5/16" to

account for the higher pressure drop.

IMPORTANT: Plumis’

most recent guidance document on hose

specification is more detailed and overrides this document if there is any ambiguity.

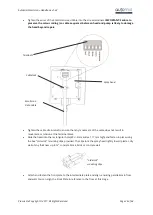

A Quick Connect with Test Point and locking pin are supplied to connect the high pressure side of the

pump to the spray head. A small o-ring is included and already attached to the Quick Connect with Test

Point. The locking pin retains the quick connector in the pump outlet but can be easily removed, for

example in order to drain water from the high pressure hose. The Test Point adaptor is required as part of

the commissioning procedure (see page 50).

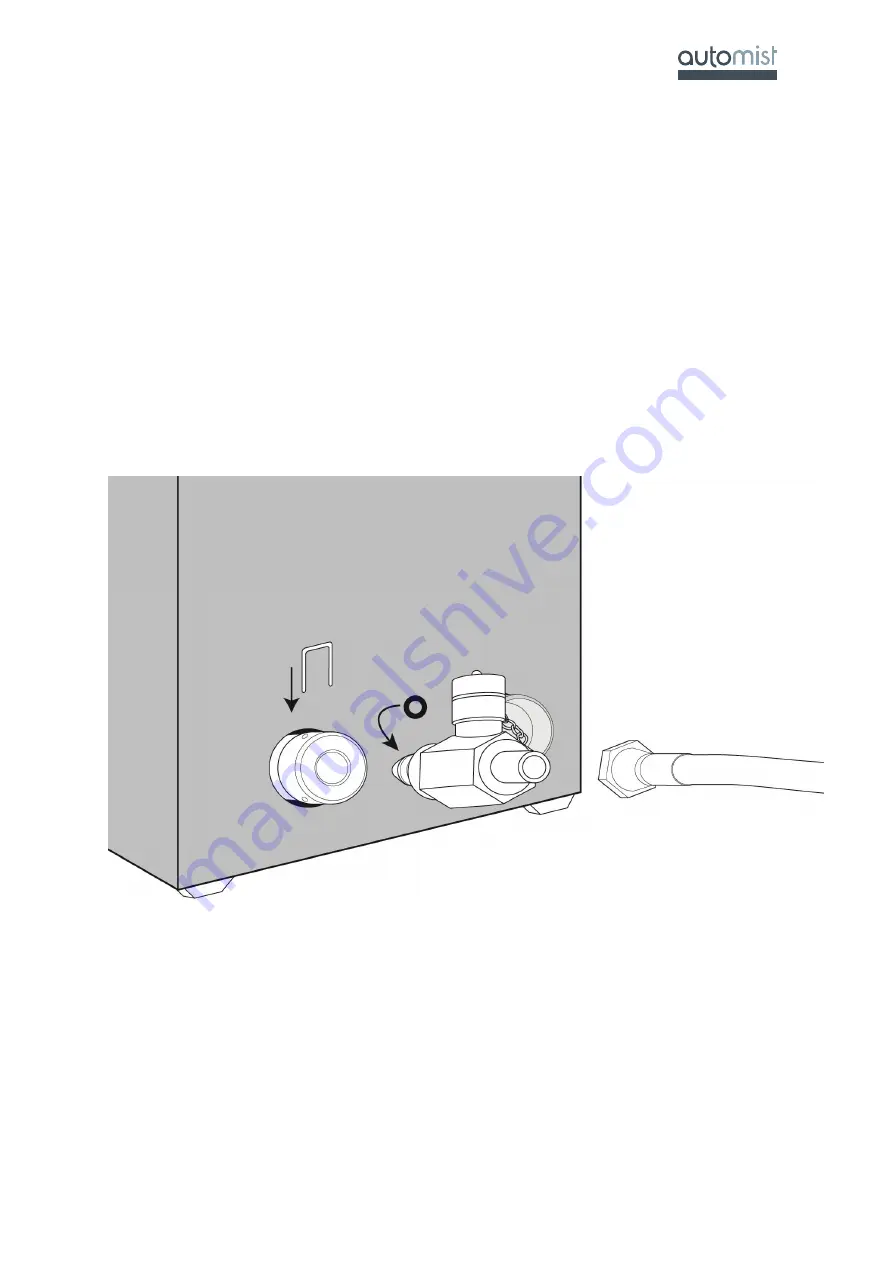

The Automist Smartscan pump unit should be housed close to a 3/4” BSP water supply with an approved

isolation valve to the check valve. A synthetic rubber washer is supplied with each device to facilitate fitting

to the flat-faced outlet.

IMPORTANT!

Do not attempt to operate the pump without the quick connector o-ring. Always properly

replace the quick connector, o-ring and locking pin after removal.

Locking pin

o-ring

Quick Connect

with Test Point