0507280010/010312/E MNF

EN - 4

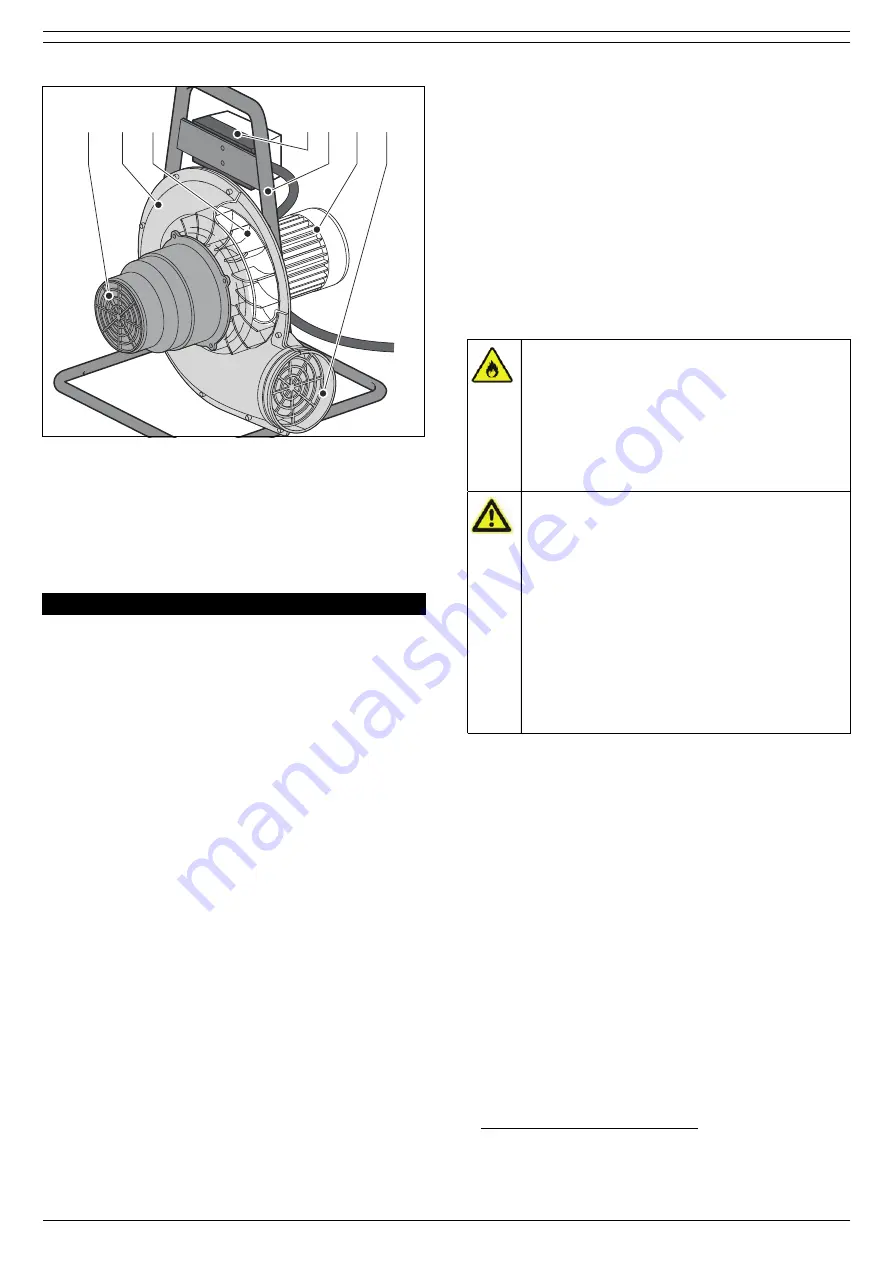

Fig. 2.1: Main components

2.2

Operation

The MNF has to be completed with an extraction hose with

magnetic foot, through which the air containing

welding fume is being extracted. An optional exhaust/extension

hose at the inlet and/or outlet side of the fan may enlarge the

working range. Discharge of the polluted air preferably to the

atmosphere.

General

The manufacturer does not accept any liability for damage to

the product or personal injury caused by ignoring of the safety

instructions in this manual, or by negligence during installation,

use, maintenance, and repair of the product mentioned on the

cover of this document and any corresponding accessories.

Specific working conditions or used accessories may require

additional safety instructions. Immediately contact your

supplier if you detect a potential danger when using the product.

The user of the product is always fully responsible for

observing the local safety instructions and

regulations. Observe all applicable safety instructions

and regulations.

User manual

•

Everyone working on or with the product, must be familiar

with the contents of this manual and must strictly observe

the instructions therein. The management should instruct

the personnel in accordance with the manual and observe all

instructions and directions given.

•

Never change the order of the steps to perform.

•

Always keep the manual with the product.

Users

•

The use of this product is exclusively reserved to well

authorised, trained and qualified users. Temporary

personnel and personnel in training can only use the product

under supervision and responsibility of skilled engineers.

•

Use common sense. Stay alert and keep your attention to

your work. Do not use the product when you are under the

influence of drugs, alcohol or medicine.

•

The product is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

•

Children must be supervised not to play with the product.

Intended use

1

The product has been designed exclusively for extracting

harmful gases and particles which are released during the most

commom welding processes. Using the product for other

purposes is considered contrary to its intended use. The

manufacturer accepts no liability for any damage or injury

resulting from such use. The product has been built in

accordance with state-of-the-art standards and recognised

safety regulations. Only use this product when in technically

perfect condition in accordance with its intended use and the

instructions explained in the user manual.

Technical specifications

The specifications given in this manual must not be altered.

Modifications

Modification of (parts of) the product is not allowed.

Installation

•

The installation of this product is exclusively reserved to well

authorised, trained and qualified engineers.

•

During installation, always use Personal Protective

Equipment (PPE) to avoid injury. This also applies for

persons who enter the work area during installation.

•

Never place the product in front of entrances and exits which

must be used for emerency services.

•

Ensure the workspace is well illuminated.

•

Use common sense. Stay alert and keep your attention to

your work. Do not install the product when you are under the

influence of drugs, alcohol or medicine.

•

Make sure that the workshop, in the vicinity of the product,

contains sufficient approved fire extinguishers.

Use

•

Inspect the product and check it for damage. Verify the

functioning of the safety features.

•

During use, always use Personal Protective Equipment (PPE)

to avoid injury. This also applies for persons who enter the

work area.

•

Check the working environment. Do not allow unauthorised

persons to enter the working environment.

•

Protect the product against water and humidity.

3

SAFETY

A

B

C

D E

F

G

1.

"Intended use" as explained in EN-ISO 12100-1 is the use for which the technical

product is suited as specified by the manufacturer, inclusive of his directions in

the sales brochure. In case of doubt it is the use which can be deduced from the

construction, the model and the function of the technical product which is

considered normal use. Operating the machine within the limits of its intended

use also involves observing the instructions in the user manual.

WARNING!

Fire hazard! Never use the product for:

- extracting flammable, glowing or burning particles

or solids or liquids

- extracting of aggressive fumes (such as hydrochloric

acid) or sharp particles

- extracting dust particles which are released when

welding surfaces treated with primer

- sucking cigarettes, cigars, oiled tissues, and other

burning particles, objects, and acids

WARNING!

Never use the product for:

- oxy-fuel cutting

- aluminium laser cutting

- arc-air gouging

- oil mist

- paint mist

- heavy oil mist in welding fume

- extraction of hot gases (more than 45°C/113°F

continuously)

- grinding aluminium and magnesium

- flame spraying

- extraction of cement, saw dust, wood dust, grit etc.

- explosive environments or explosive substances/

gases

Note: this list is not all-embracing

Summary of Contents for 7020-MNF

Page 35: ......