0507280010/010312/E MNF

EN - 5

•

Make sure the room is always sufficiently ventilated; this

applies especially to confined spaces.

Service, maintenance and repairs

•

Observe the maintenance intervals given in this manual.

Overdue maintenance can lead to high costs for repair and

revisions and can render the guarantee null and void.

•

During service, maintenance and repair jobs, always use

Personal Protective Equipment (PPE) to avoid injury. This

also applies for persons who enter the work area.

•

Always use tools, materials, lubricants and service

techniques which have been approved by the manufacturer.

Never use worn tools and do not leave any tools in or on the

product.

•

Safety features which have been removed for service,

maintenance or repairs, must be put back immediately after

finishing these jobs and it must be checked that they still

function properly.

4.1

Tools and requirements

- screwdriver or hexagon wrench to fasten hose clamp

4.2

Unpacking

Check that the product is complete. The package should

contain:

MNF:

- portable extraction fan with 6 m mains cord (without plug)

SUS-5/160:

- 5 m extraction hose Ø 160 mm with magnetic foot

- hose clamp

EXS-5/160 (option):

- 5 m exhaust/extension hose Ø 160 mm

- hose clamp

- adapter

If parts are missing or damaged, contact your supplier.

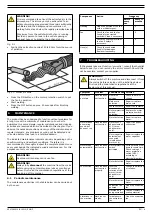

4.3

Mounting the mains plug

The machine comes without plug.

•

Mount an appropriate earthed plug, preferably a plug with

phase inverter (three-phase motor only).

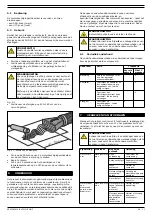

4.4

Connection of the hose(s)

The maximum hose length to be connected is 20 meters. Refer

to Fig. II on page 33 for the possible configurations.

A = MNF

B = SUS-5/160

C = EXS-5/160

•

Define the desired configuration.

•

Interconnect the hoses, if applicable, with an adapter. Fasten

each hose to the adapter using a hose clamp.

•

Connect the hose(s) to the outlet and/or inlet opening of the

portable fan using a hose clamp.

In case of two or three interconnected exhaust/extension hoses,

one adapter becomes redundant.

4.5

Connection to the mains

•

Connect the machine to the mains.

•

Check the direction of rotation of the motor (three-phase

motor only).

The direction of rotation can be checked in different ways;

- using a flowmeter; airflow at the nozzle should be min. 1000

m

3

/h (keep hose straight)

- by checking the sound and the air volume

If the fan is running but there is hardly any extraction, the

direction of rotation of the motor is probably wrong. A correct

direction of rotation is indicated by a high air volume at a low

sound level. The difference can be checked by inverting the

phases.

•

If necessary: invert the connection of the phases.

5.1

Control

The motor protection switch contains two push buttons:

- an ON button (black)

- an OFF button (red)

5.2

Use

Since it concerns a portable unit, it can be used at any desirable

place. Due to the magnetic foot on the nozzle of the SUS-5/160,

the welding fume can be extracted near the source.

•

Connect the portable fan to the mains.

•

Position the outlet of the fan (via outlet opening or exhaust/

extension hose) outside the working area.

ATTENTION!

Service, maintenance and repairs should only be

performed in accordance with directive TRGS 560 by

authorised, qualified and trained persons (skilled)

using appropriate work practices.

WARNING!

Before carrying out service, maintenance and/or

repair jobs:

- fully disconnect the product from the mains

WARNING!

Never drive over the mains cord with any device.

4

INSTALLATION

WARNING!

Plug to be installed in accordance with local

requirements. This is strictly reserved for skilled and

authorised service engineers.

WARNING!

Make sure the product is suitable for connection to the

local mains. Information about the connection voltage

and frequency can be found on the identification plate.

The cables must be connected in conformance with the

local rules and regulations and can only be carried out

by well qualified and authorised technicians.

5

USE

WARNING!

Never use the fan without extraction hose.

CAUTION!

Never put any object (e.g. a stick) or limb in the inlet

or outlet opening.

CAUTION!

Do not position the fan in places where it is exposed to

vibrations or heat radiation from heat sources.

Summary of Contents for 7020-MNF

Page 35: ......