0000110291/011222/B MiniMan-75

6

6.2

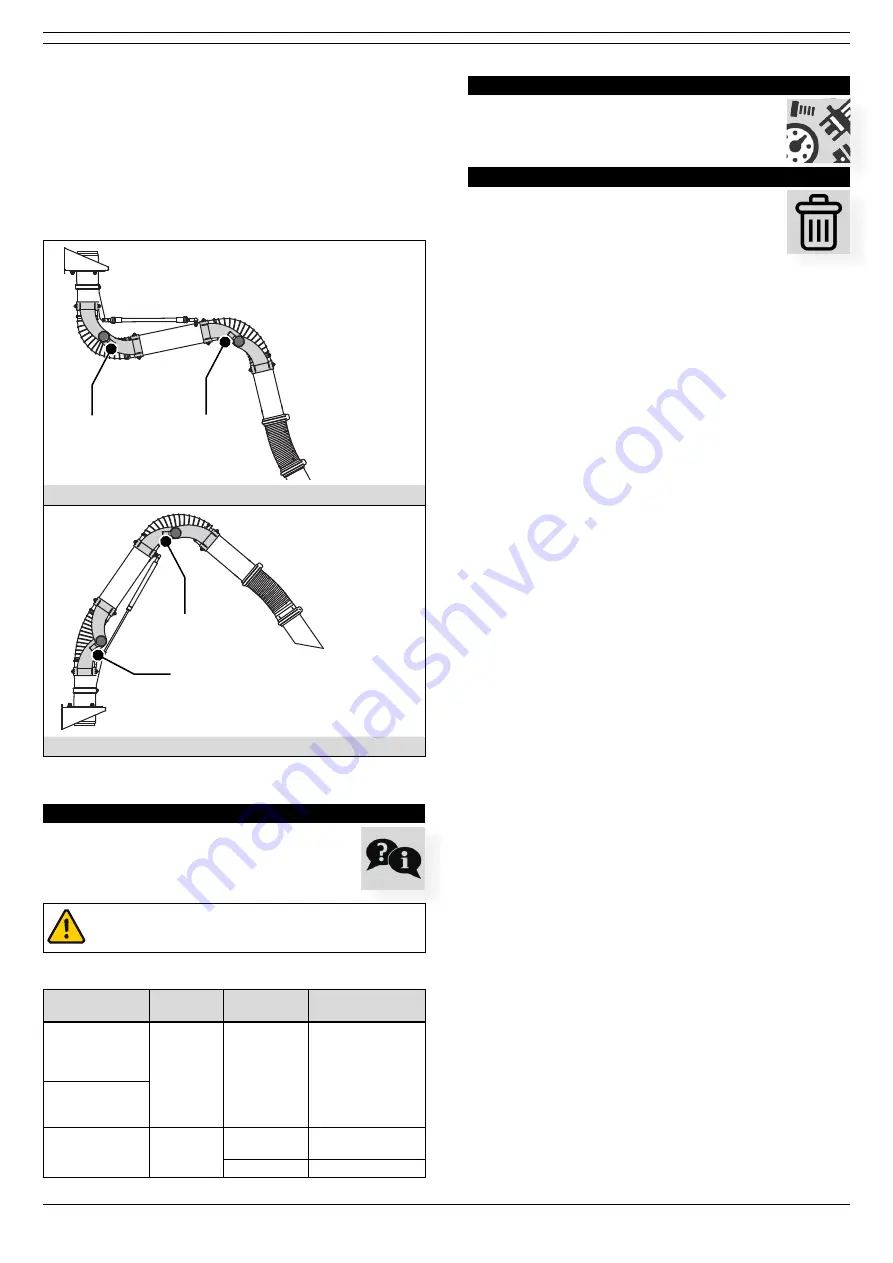

Arm adjustment

If the extraction arm, or a part of it, does not stay in the

desired position, you must adjust the friction.

• Determine which part of the arm needs more or less

friction;

- inner tube (ref. Fig. 2.1E): adjust friction joint A

- outer tube (ref. Fig. 2.1F): adjust friction joint B

A

A

B

B

MiniMan

H

A

A

B

B

MiniMan

S

Fig. 6.1 Adjustment points

7

TROUBLESHOOTING

If the product does not function (correctly), consult

the checklist below to see if you can remedy the

error yourself. Should this not be possible, contact

your supplier.

WARNING!

Obey the safety regulations that are written in

chapter 3 when you carry out the activities below.

Symptom

Problem

Possible

cause

Solution

The extraction

arm does not stay

in the desired

position

Escape of

fume or

dust; no

proper

extraction

Friction

setting is not

correct

Adjust the friction;

You cannot get

the arm in the

desired position

Escape of fume or

dust; insufficient

extraction

No proper

extraction

Loose hose(s) Fasten the hose(s)

properly

Hose damage Replace the hose(s)

8

SPARE PARTS

The following spare parts are available for the

product;

- refer to exploded view Fig. V on page 9

9

DISPOSAL

After life of the product, dispose of it in accordance

with federal, state or local regulations.