0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 6

ENGLISH

4.1

MDB filter system

Before installing the components of SHIELD fire safety

solutions, make sure the Cart-D filter cartridges of the

connected MDB filter system are properly installed. To check

this, refer to the corresponding manual.

•

Securely check the installation of the Cart-D filter cartridges.

4.2

Tools and requirements

- connection wire: 5 x 20 AWG

- connection wire: 5 x 20 AWG shielded cable

- electric drill

- self-tapping screws

- mounting material ShieldControl 5k1

- metal cable glands

- duct support material (depending on weight of sliding valves)

- lifting and climbing gear

- existing duct: angle grinder or jigsaw

4.3

Installation and commissioning

To avoid accidental fire alarms and the activation of FlameShield

fire extinguishing generators, the following installation and

commissioning sequence should be followed. Deviation from

this sequence is allowed, provided the FlameShield module(s)

is/are always the last to be connected, even after having

performed the functional tests.

1. Filter/fan installation

2. System control panel SCP

3. ShieldControl panel (

without power

)

4. Detectors (heat, sparks, smoke)

5. Valves (sliding solenoid valve)

6. FlameShield fire extinguishing generators (

isolated

)

•

Refer to chapter 13 for extensive commissioning checklist.

4.4

Functional test

To perform any functional test, the following instructions should

be followed.

•

Ensure that the FlameShield module(s) is/are isolated.

•

Perform detector test. Sound alarm will go off.

•

Check fire zone (

FIRE IN ZONE

).

•

Press the

SIGNAL SILENCE

button on the ShieldControl panel to

suppress alarm.

•

Press the

SYSTEM RESET

button.

To proceed with testing:

•

Restart procedure.

If testing has been completed:

•

Reconnect the FlameShield module(s).

•

Make sure the panel is in

RUN

mode.

5.1

Product description and operation

ShieldControl 5k1 is a fire detection panel

1

with a separate

manual call point. It has three detection zones all of which are

capable of activating the FlameShield fire extinguishing

generators.

The fire detection panel makes it possible to connect additional

manual call points.

ShieldControl has two back-up batteries to allow for continuous

operation in the event of power failure.

5.2

Installation

To be sourced locally:

- connection wire: 5 x 20 AWG shielded cable

- mounting material

- metal cable glands

Location

- on the wall or at a convenient location close to the filter

installation

- at eye level

- indoors

Ambient conditions

- Min. temperature: –5°C (23°F)

- Max. temperature: +40°C (104°F)

- Relative humidity: max. 95%

The ShieldControl housing is NEMA 1 rated. It must be shielded

from excessive dust, welding sparks and grinding sparks, if any,

by e.g. an enclosure.

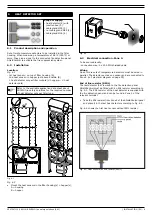

Installation

To install the ShieldControl panel, proceed as follows.

•

Mount the ShieldControl panel at all four mounting points.

Use suitable fixtures so that the panel cannot move after it

has been installed.

5.3

Fire alarm sounder

Installation, tone selection and volume control of the fire alarm

sounder are described in the installation manual supplied with

the product.

•

Mount the fire alarm sounder at an appropriate position.

•

Select the desired tone.

•

Adjust the noise to the desired level.

4

INSTALLATION (GENERAL)

WARNING!

Improper installation of the Cart-D filter cartridges will

cause internal leakage and a reduced filter efficiency.

In combination with SHIELD fire safety solutions it can

lead to a false fire alarm.

5

SHIELDCONTROL 5K1

Scope of supply:

- fire detection panel

- battery pack (2)

- fire alarm sounder

- manual call point

- EOL resistor-diode

- detonation simulator

- key (2)

1. UL Standard 862

WARNING

To prevent damage, do

not

mount the ShieldControl

panel close to sources of excessive heat.