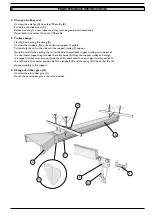

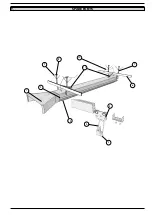

CATChER AND CONNECTION SOCKET

1

2

3

1

1. VSR rail

2. Catcher

3. Connection socket, d=160 mm/6,3”

Mount the catcher at the exit end of the rail.

Drill 8.5 mm holes in the profile according to the hole structure on the catcher.

The catcher is to be mounted with 2 pcs M8x25 and 2 pcs M8x45 with nuts.

Mount the connection socket, d=160 mm/6,3”, to the opposite end of the rail with 4 pcs

M8x20.

PUM_VSR_100209_EN

9/20

0

7.

MOUNTING INSTRUCTION

WARNING

PRODUCT MAY CONTAIN SHARP EDGES

Use care when servicing unit.

Failure to do so could result in minor personal

injury.