COMPRESSOR

HOT GAS BYPASS VALVE

Refrigerant compressors normally do not need any

maintenance. The compressor will unload or adjust for

different load conditions with the refrigeration controls.

Any time power is applied to the compressor, and the

suction pressure is higher than the specified readings,

the compressor is either not pumping or failed

electrically, or tripped “off” at the overload protection. If

the compressor does not automatically reset within a few

minutes, it requires servicing. Service must be

performed by a qualified refrigeration technician.

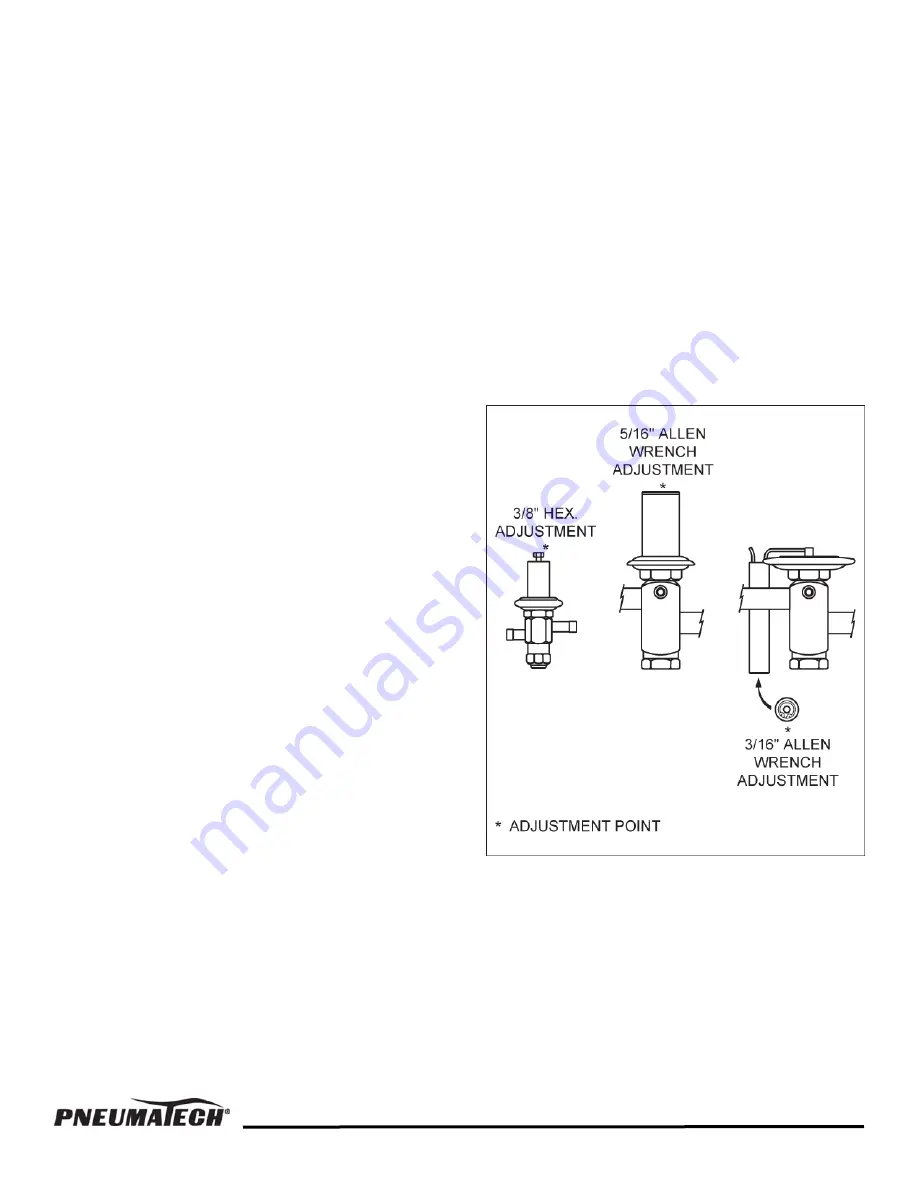

These air dryers come equipped with modulating hot gas

bypass valves. This valve maintains the refrigerant

suction pressure in varying load conditions. The dryer

will run from no load to full load conditions without

freeze-up. The operation of this valve is automatic. If the

valve needs adjustment, turn the adjusting stem

clockwise to raise the suction pressure, and

counterclockwise to lower the suction pressure. This

adjustment should be made under a no-load condition

only. When the adjustment is made, turn one quarter of

a turn at a time, and wait 3 to 5 minutes between

adjustments. Once the adjustment is complete, secure

the adjusting stem with the locknut that is provided.

Careful adjustment of this valve is necessary for normal

operation of the air dryer. Hot gas bypass valve

adjustment may be made by maintenance personnel.

See Figure 5.

EXPANSION VALVE

Air dryers equipped with an automatic expansion valve

are factory adjusted for proper cooling. The valve

adjusting stem is secured with a lock nut at the factory to

maintain proper setting. Larger units are equipped with a

thermostatic expansion valve, factory set to maintain a

superheat of 8 to 10°F (-13 to -12°C). These valves do

not need adjustment in normal operation. Generally,

superheat adjustments are needed only at the time of

valve replacement. Expansion valve service must be

performed by a qualified refrigeration technician.

FIGURE 5 — HOT GAS BYPASS VALVE ADJUSTMENTS

13

Summary of Contents for AD Series

Page 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Page 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Page 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Page 22: ...21 ...

Page 23: ...22 ...