Pub. No. OM-A-10E — April 2004

11

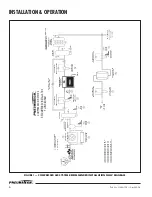

FIGURE 2 — SDG-1: SEQUENCE OF OPERATION DIAGRAM

Shutdown Procedure

Externally Heated dryers are typically installed in 24 Hr.

operations. The dryers operate on a standard time cycle

of 8 hours, 4 hours drying and 4 hours regenerating. This

cycle should not be interrupted (except for servicing). If the

dryer needs to be shut down for a certain shift or

weekend; the dryer should be turned off at the end of the

4 hour regenerating cycle, and with both towers at line

pressure. If servicing is required advance the time

sequence so the purge valves close, and pressurize both

towers. At this time, the dryer can be turned off.

1.

If the compressed air system has been

piped with a bypass around the dryer, then

the following should be completed

:

a. Open the bypass valve to allow process flow to

continue downstream, then close the dryer outlet

isolation valve.

b. Turn the dryer ON/OFF switch to the OFF

position.

c. Close the dryer inlet isolation valve on the dryer

bypass piping. At this time the dryer is isolated

and can be depressurized for servicing.

2.

If the compressed air system has not been

piped with a bypass, then the following

should be completed:

a. Turn the power switch to the OFF position.

b. The tower switching valves are normally open

valves; therefore, with the power off the inlet

valves to the towers will be open, and the purge

valves will close. This will give you extended

drying time until desiccant chambers are

saturated.

1

LEFT TOWER

SWITCHING

ON

OFF

ZERO

ZERO

240 MINUTES

240 MINUTES

480 MINUTES

480 MINUTES

ZERO

R TOWER

HEATING

R TOWER

COOLING

240 MINUTES

150

390

480 MINUTES

2

RIGHT TOWER

SWITCHING

ON

OFF

3

LEFT TOWER

REGENERATING

ON

OFF

4

RIGHT TOWER

REGENERATING

ON

OFF

5

DEMAND

CYCLE

ON

OFF

N/A

HEATER

TIMING STAGE:

ON

OFF

6

LEFT TOWER

DEPRESSURIZING (OPT.)

ON

OFF

7

RIGHT TOWER

DEPRESSURIZING (OPT.)

ON

OFF

L TOWER

HEATING

L TOWER

COOLING