POK SAS - ZI Les Guignons - 10400 Nogent-sur-Seine - FRANCE

Tel : +33 (0)3 25 39 84 78 - Fax : +33 (0)3 25 39 84 90 - Email : france@pok.fr - Web : www.pok.fr

MOP_LAM_01289_EN R

ev

.A - 18/08/2014 - Cop

yright© POK S

A

S - Illustr

ations are only informativ

e

4

• Introduction

Please read this manual before using the equipment.

Use, maintenance, or any other operation of the equipment must be done by staff trained for the use of this

equipment and aware of any safety rules.

While using the fire nozzle (use, maintenance, installation, ...) it is important to wear personal protective

equipment.

• Dismantling and warranty

This equipment has a warranty of 1 year for any fabrication default, except where covered by special written

agreement.

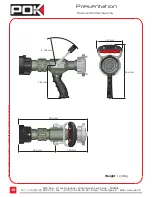

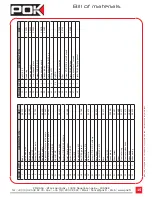

The exploded view and bill of materials are not a dismantling manual.

Any dismantling or maintenance operation of the device must be done with water supply turned off.

Dismantling and/or modification of the equipment outside POK SAS factory is allowed only in compliance

with procedures described in this manual, and therefore does not affect the warranty.

If the equipment is repaired, the spare parts must be supplied by POK SAS. If not, technical characteristics

listed in this document won’t be valid, the warranty will void and POK SAS responsibility will not apply.

If maintenance operation damage parts, the warranty may not apply if the procedure has not been carried

out properly in accordance with this manual.

Although this is not explicitly stated in instructions, use and wear of protective equipment are obligatory

during maintenance operation. POK SAS cannot be responsible of any damage or accident which may occur

during the dismantling. If this obligation is not met, please refer to the tools instructions guides for more

details.

Only POK SAS can ensure proper and safe functioning of the equipment. Therefore POK SAS will not be liable

for any damage or accident caused by dismantling of the equipment outside its workshop.

Do not modify the equipment, it may not be working or be dangerous for use. Any modification not approved

by POK will void the warranty.

Information