Instruction manual PP14-366

3/7

III. Assembly

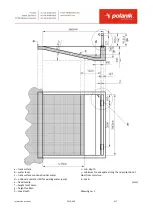

The barrier is designed to be mounted on the synthetic surface of the water jump pit edge, provided that under the

synthetic surface there is a concrete base layer made of concrete class C20/25 or higher and min. 130 - 150 mm thick.

If the base layer does not comply with the mentioned requirements, two foundation blocks are to be made according

to the below diagram.

[mm]

1.

the edge of the water jump pit

2.

foundation block, minimal dimensions: 500 x 500 x 500 [mm] made of min. C20/25 concrete

To install the barrier to the edge of the water jump pit use the included steel expansion anchors HLC 16x140/90

according to

their producer’s instructions (see

). The installation is done in the following way:

1)

screw the barrier legs to the top beam with the included screws,

2)

position the barrier on the edge of the water jump pit according to the drawing no. 1 and no. 2 (pages 4 and

5), mark the points where to drill the wholes,

3)

use the drill bit dia. 16 mm to drill wholes min. 130-150 mm deep,

4)

clean the wholes (e. g. with vacuum cleaner)

5)

position the barrier on the edge of the water pit,

6)

put the anchors into the wholes,

7)

screw down the nuts with approximate force 50 Nm.