11. EFI SYSTEM OF SQR 472ENGINE

11-19

(

2

)

Characteristic data

measure

new

250 hours after the bench test

Exhaust temperature characteristics of data set

350

℃

850

℃

350

℃

850

℃

Mixed gas concentration sensor voltage (Mv)

750~920

710±70

840±80

710±70

Mixed gas concentration sensor voltage (Mv)

40~100

55±30

20±50

40±40

The sensing element resistance (Km)

1~5

≤

0.1

≤

1.5

≤

0.3

Response time (Ma) (600mA to 300mA)

100~300

<

200

<

400

<

400

Response time (Ma) (600mA to 300mA)

60~250

<

200

<

400

<

400

(

3

)

Sensor data

measure

value unit

At room temperature, the heating element (500V DC)

≥

1 M

Ω

Exhaust temperature 350

℃

≥

10 M

Ω

The new sensor with the

insulation resistance

between element and the

sensor joint

Exhaust temperature 850

℃

≥

100 K

Ω

Rated voltage

12

V

Working voltage

12

至

14

V

Working voltage up to 1% of the total life can be maintained, the exhaust

temperature

≤

350

℃

15 V

To maintain the working voltage of up to 75 seconds (exhaust temperature

≤

350

℃

)

24 V

The power supply

voltage on the plug

The test voltage

13

V

The working voltage is 13V, the heating current at thermal equilibrium (exhaust temperature is 35

℃

, the

exhaust velocity of about 0.7M/s)

12 W

The working voltage is 15V, the heating current thermal equilibrium (350

℃

, the exhaust of greenhouse

gas flow velocity of about 0.7m/s)

5 A

Fuse filament heating circuit

8 A

(4) The use of life

Oxygen sensor life associated with gasoline lead content, see the following table.

Gasoline lead content (g/L)

Life (km)

≤

0.6 30000

≤

0.4 50000

≤

0.15 80000

≤

0.005 (gasoline)

160000

4) Installation notes

Oxygen sensor should be installed in the exhaust gas mixing place, and when a vehicle moves, air cooling metal shell and wire

should be flow.

On the exhaust pipe can ensure the representative of the exhaust components and can meet the requirements of the temperature limit

position. Installation location should be as close as possible to the engine. The exhaust pipe should be provided with screw, screw in

oxygen sensor used for.

nstall the attitude of oxygen sensor

Oxygen sensor should be installed with the horizontal plane angle is greater than or equal to 45 degrees, and the sensor tip down, to

avoid the cold start of condensed water accumulated between the sensor housing and sensing ceramic tube.

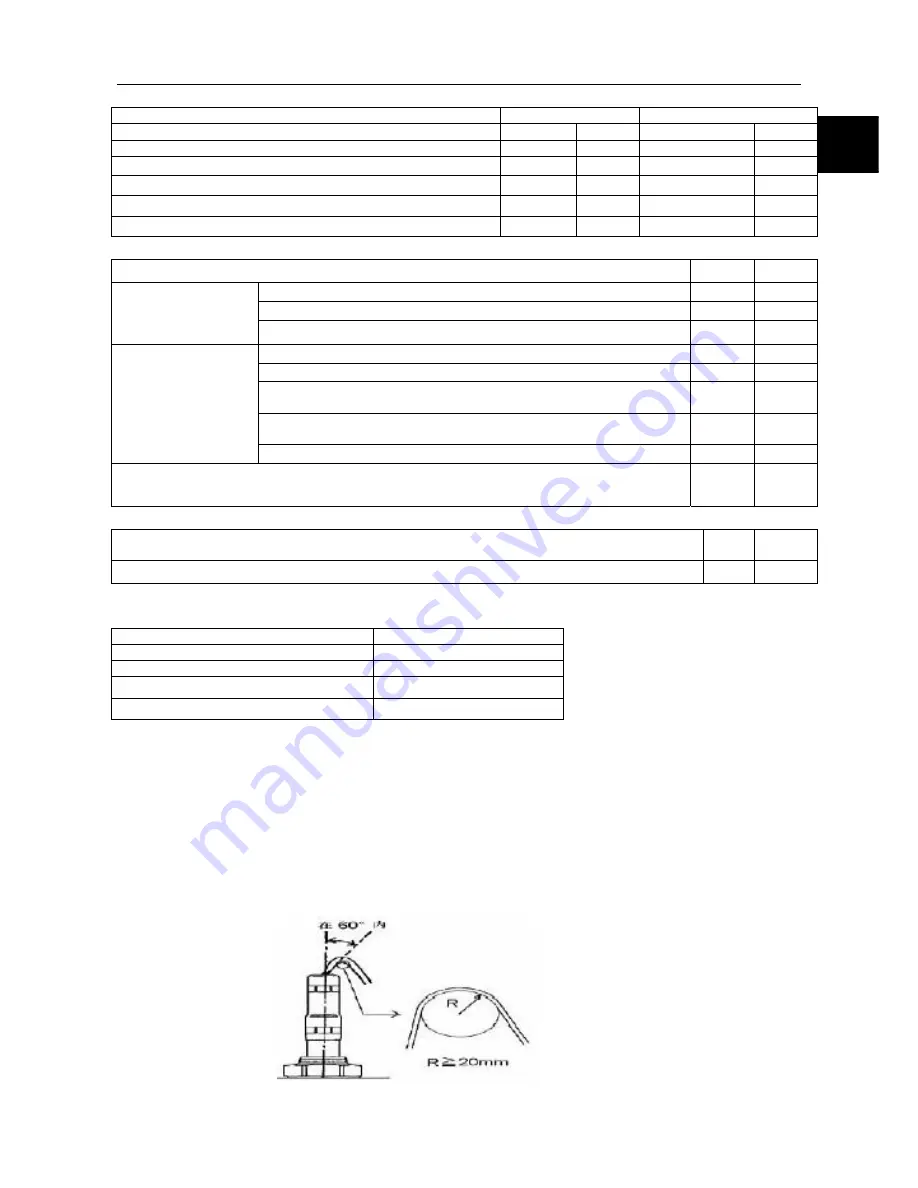

Oxygen sensor wire can not bend more than 60 degrees, the bend arc radius is greater than or equal to 20 mm, and the wire should

not bear the tensile stress. The following diagram.

11

Summary of Contents for 1100 GKE OutLaw

Page 1: ...Service Manual 1100GKE 4 4...

Page 62: ...4 COOLING SYSTEM 4 6 Cooling System Chart...

Page 158: ...10 CVT TRANSMISSION SYSTEM 10 7 5 Appearance installation dimension map Fan shaped array 10...

Page 165: ...11 EFI SYSTEM OF SQR 472ENGINE 11 3 3 The ECU control principle diagram...

Page 166: ...11 EFI SYSTEM OF SQR 472ENGINE 11 4 4 The ECU function module layout...

Page 260: ......