Page 6

Page 3

INSTALLATION NOTES & TROUBLESHOOTING GUIDE

OPERATION & MAINTENANCE INSTRUCTIONS

Installation Notes

When there is no flow, the water in the cell will become warm, as the UV disinfection system lamp is always on. To

remedy this, run cold water tap anywhere in the house for a minute to flush out the warm water.

As the system requires time to reach its full operating capacity, please allow the disinfection system to operate 3-5

minutes prior to using the water from unit. In addition, to clear any air or debris form the system, open the faucet and

allow water to run through the disinfection system for 2-3 minutes.

Troubleshooting Guide

B. Quartz Sleeve Replacement And/Or Cleaning:

If the water contains any hardness minerals (calcium or magnesium), iron or

manganese, the quartz sleeve will require periodic cleaning. To remove the quartz

sleeve, first the UV lamp as outlined above:

a) Shut off water supply and drain all lines.

b) Drain the UV chamber (use a small bucket under the unit to prevent a spill),

using drain port provided.

c) Remove nuts from chamber, checking for the free floating spring inside

sleeve at the opposite end to the lamp connection (do not allow quartz

sleeve to fall).

d) Carefully remove O-rings from the quartz sleeve. As the O-ring may tend to

adhere to the quartz sleeve, it is recommended to replace the O-rings annually.

e) Clean the quartz sleeve with a cloth soaked in

CLR

, vinegar or some other

mild acid and then rinse avoiding the introduction of any water to the inside

of the sleeve.

f) Re-assemble the quartz sleeve with spring in the UV chamber allowing the

sleeve to protrude an equal distance from both ends of the UV chamber.

g) Wet the O-rings and slide onto each end of the quartz sleeve and reassemble

the gland nuts (hand tight is sufficient).

h) Re-tighten all connections, turn on water and check for leaks.

i) Re-install the UV lamp and lamp connector as per prior instructions.

j) Reconnect system to power source.

Note:

If the system is put on a temporary by-pass or if it becomes contaminated after the disinfection system,

it will be necessary to shock the system with household bleach for a full 20 minutes before resuming use of the water.

CAUTION:

When performing any work on the disinfection system unplug the unit first and

never look directly at the burning UV lamp.

SYMPTOM

POSSIBLE CAUSES

REMEDY

PRESSURE

DROP

The sediment pre-filter is

clogged

Replace filter cartridge with appropriate

five micron cartridge. NOTE: Check source

of water supply as fluctuations may occur in

source pressure

HIGH

BACTERIA

COUNT

Quartz sleeve is stained or

dirty

Clean sleeve with scale cleaner and eliminate

source staining problem

The UV lamp is spent

Replace UV lamp

Change in feedwater quality

Have the source water tested to ensure it is

still within the allowable parameters for use

with this unit

Contamination after

disinfection system

It is imperative that the effluent water

stream be shocked with chlorine after the

water leaves the disinfection system the

disinfection system must have a bacteria free

distribution system to work effectively

WARM

PRODUCT

WATER

Common problem caused

by infrequent use

Run water

WARM WATER

APPEARS

“MILKY”

Caused by air in the water

lines

Run water until air is purged

UNIT LEAKING

WATER

Problem with O-ring seals

(on gland nuts and/or

sensor probe on monitored

units)

Ensure the O-ring is in place, check for cuts or

abrasions, clean O-ring, moisten with water

and re-install, replace if necessary

Condensation on reactor

chamber caused by

excessive humidity

Check location of disinfection system and

control humidity

Inadequate inlet/outlet port

connections

Check thread connections, re-seal with Teflon

tape and re-tighten

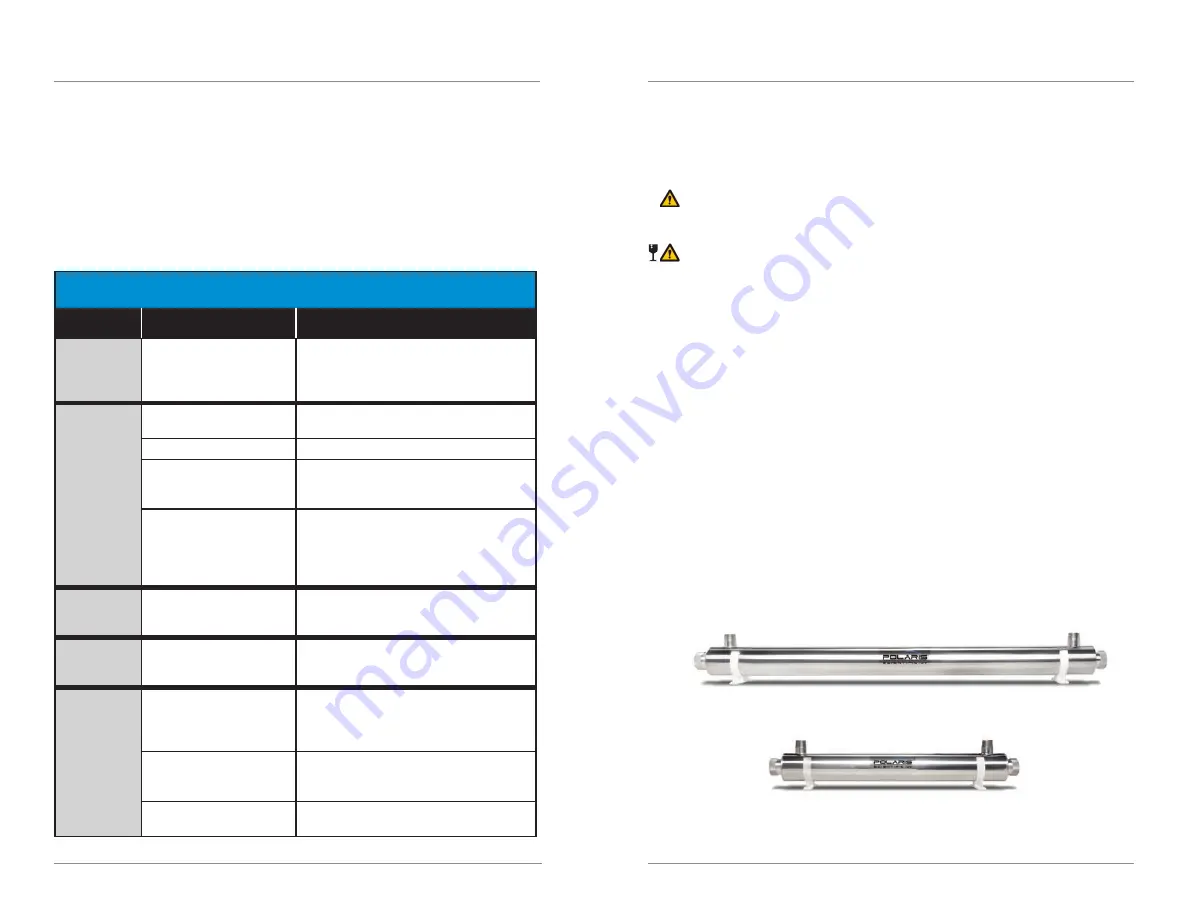

UVA-12C

UVA-6C