BRAKES

9.5

BRAKE NOISE

TROUBLESHOOTING

Dirt or dust buildup on the brake pads and disc is the

most common cause of brake noise (squeal caused

by vibration). If cleaning does not reduce the

occurrence of brake noise, Permatex

t

Disc Brake

Quiet can be applied to the back of the pads. Follow

directions on the package. This will keep pads in

contact with caliper piston(s) to reduce the chance of

squeaks caused by dirt or dust. See table on the next

page.

Brake Noise Troubleshooting

Possible Cause

Remedy

Dirt, dust, or im-

bedded material

on pads or disc

Spray disc and pads

with CRC Brake Kleen

t

or equivalent non-flam-

mable aerosol brake

cleaner. Remove pads

and/or disc hub to clean

imbedded material from

disc or pads.

Pad(s) dragging on

disc (noise or

premature pad wear)

Improper adjustment

Insufficient lever or

pedal clearance

Master cylinder res-

ervoir overfilled

Master cylinder

compensating port

restricted

Master cylinder pis-

ton not returning com-

pletely

Caliper piston(s) not

returning

Operator error (riding

the brake / park brake

applied)

Adjust pad stop

(front calipers)

Check position of

controls & switches.

Set to proper level

Clean compensating port

Inspect.

Repair as necessary

Clean piston(s) seal

Educate operator

Loose wheel hub or

bearings

Check wheel and hub

for abnormal

movement.

Brake disc warped or

excessively worn

Replace disc

Brake disc

misaligned or loose

Inspect and repair as

necessary

Noise is from other

source (chain, axle,

hub, disc or wheel)

If noise does not

change when brake is

applied check other

sources. Inspect and

repair as necessary

Wrong pad for

conditions

Change to a softer or

harder pad

HYDRAULIC

CALIPER BLEEDING

T

his caliper is a single piston design. The caliper

pistons are “T”-shaped, which allows both hand and

foot brake to use the same caliper piston, but remain

separated by seals. The hand brake system applies

hydraulic pressure to both front calipers and only the

outer diameter of the rear caliper pistons.

The

auxiliary (foot) brake applies pressure to the inner

portion of the rear caliper pistons. Because the hand

and foot brake hydraulic systems are separate, there

are also two bleed screws -- one for the outer fluid

chamber (hand brake), and one for the inner fluid

chamber (foot brake).

The basic procedure for

bleeding the brake system is the same as outlined in

this chapter, however, each system must be bled

separately.

Hydraulic Auxiliary Brake inspection and adjustment

is outlined in Chapter 2.

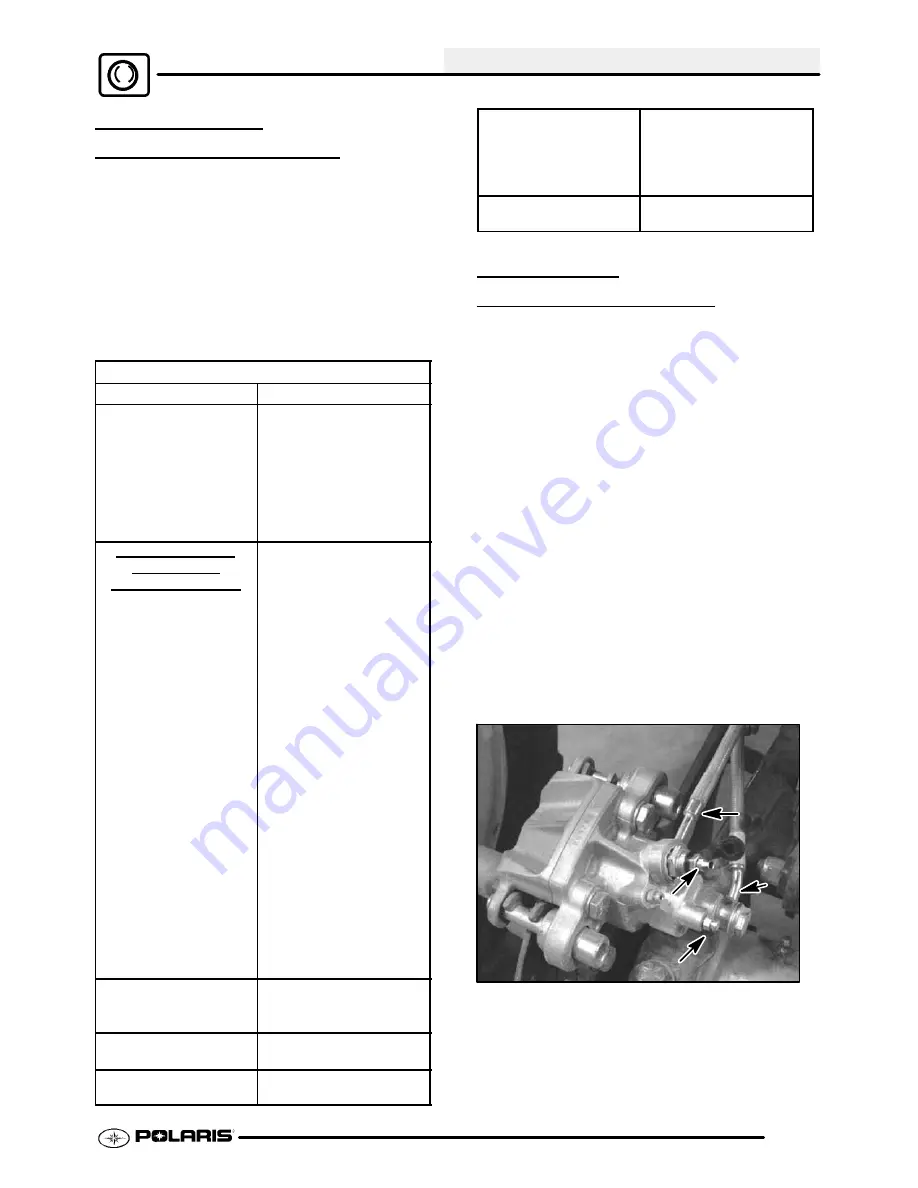

NOTE: Top (Uppermost) bleed screw (A) and brake

line (A) is for hand brake system

Lower screw (B) and brake line (B) is for auxiliary (foot)

brake system.

B

B

A

A

PartShark.com

877-999-5686

Summary of Contents for 2009 Trail Blazer 330

Page 94: ...ENGINE 3 48 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 110: ...FUEL SYSTEM CARBURETION 4 16 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 124: ...BODY STEERING SUSPENSION 5 14 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 196: ...ELECTRICAL 10 4 REVERSE LIMIT SYSTEM P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 226: ...ELECTRICAL 10 34 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 227: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 228: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 229: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 230: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...