ELECTRICAL

10.23

6.

Check specific gravity of each cell with a

hydrometer to assure each has a reading of 1.270

or higher.

BATTERY

TERMINALS/TERMINAL BOLTS

Use Polaris corrosion resistant Nyogel

t

grease (PN

2871329) on battery bolts. See Battery Installation.

CONVENTIONAL BATTERY

INSPECTION/REMOVAL

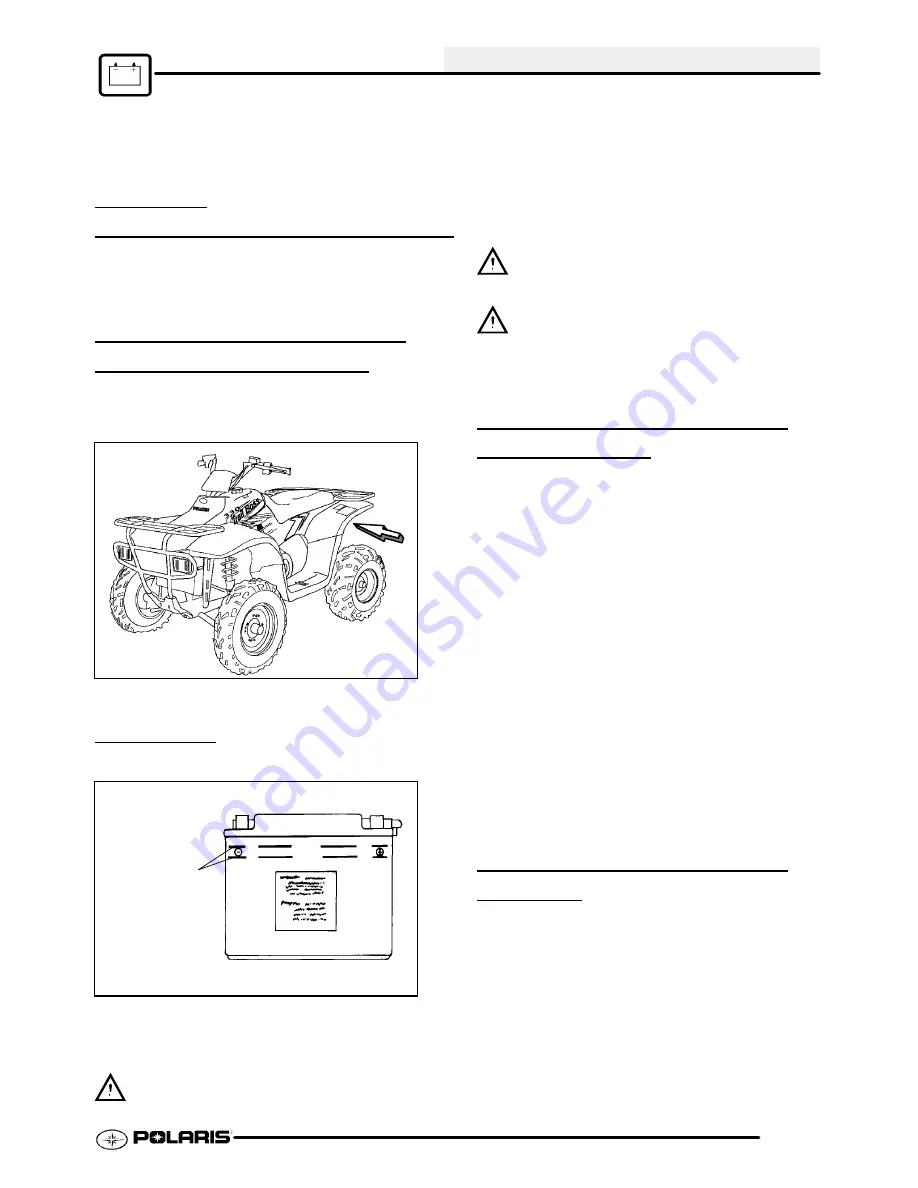

The battery is located under the seat and the right rear

fender.

Battery

Location

Inspect the battery fluid level. When the battery fluid

nears the lower level, remove the battery and fill with

distilled water only to the upper level line. To remove

the battery:

Maintain

between upper

and lower level

marks

1.

Disconnect holder strap and remove covers.

2.

Disconnect battery negative (-) (black) cable first,

followed by the positive (+) (red) cable.

CAUTION

Whenever removing or reinstalling the battery,

disconnect the negative (black) cable first and

reinstall the negative cable last!

3.

Remove the battery.

4.

Remove the filler caps and add distilled water

only as needed to bring each cell to the proper

level. Do not overfill the battery.

Refill using only distilled water.

Tap water

contains minerals which are harmful to a battery.

Do not allow cleaning solution or tap water inside

the battery. Battery life may be reduced.

5.

Reinstall the battery caps.

CONVENTIONAL BATTERY

INSTALLATION

1.

Clean battery cables and terminals with a stiff wire

brush. Corrosion can be removed using a solution

of one cup water and one tablespoon baking soda.

Rinse well with clean water and dry thoroughly.

2.

Route the cables correctly.

3.

Reinstall battery, attaching positive (+) (red) cable

first and then the negative (-) (black) cable. Coat

terminals and bolt threads with Nyogel

t

Grease

(PN 2871329).

4.

Install clear battery vent tube from vehicle to battery

vent. WARNING: Vent tube must be free from

obstructions and kinks and securely installed. If not,

battery gases could accumulate and cause an

explosion.

The vent tube should be routed away

from frame and body to prevent contact with

electrolyte. Avoid skin contact with electrolyte, as

severe burns could result. If electrolyte contacts the

vehicle frame, corrosion will occur.

5.

Reinstall the holder strap.

CONVENTIONAL BATTERY

TESTING

Whenever a service complaint is related to either the

starting or charging systems, the battery should be

checked first.

Following are three tests which can easily be made on

a battery to determine its condition:

OCV Test,

Specific Gravity Test and Load Test.

PartShark.com

877-999-5686

Summary of Contents for 2009 Trail Blazer 330

Page 94: ...ENGINE 3 48 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 110: ...FUEL SYSTEM CARBURETION 4 16 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 124: ...BODY STEERING SUSPENSION 5 14 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 196: ...ELECTRICAL 10 4 REVERSE LIMIT SYSTEM P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 226: ...ELECTRICAL 10 34 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

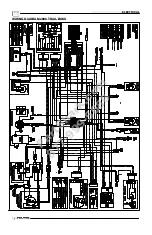

Page 227: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 228: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

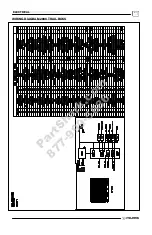

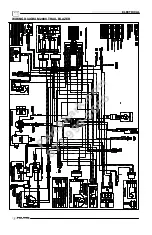

Page 229: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 230: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...