MAINTENANCE

2.25

INTAKE VALVE CLEARANCE

ADJUSTMENT

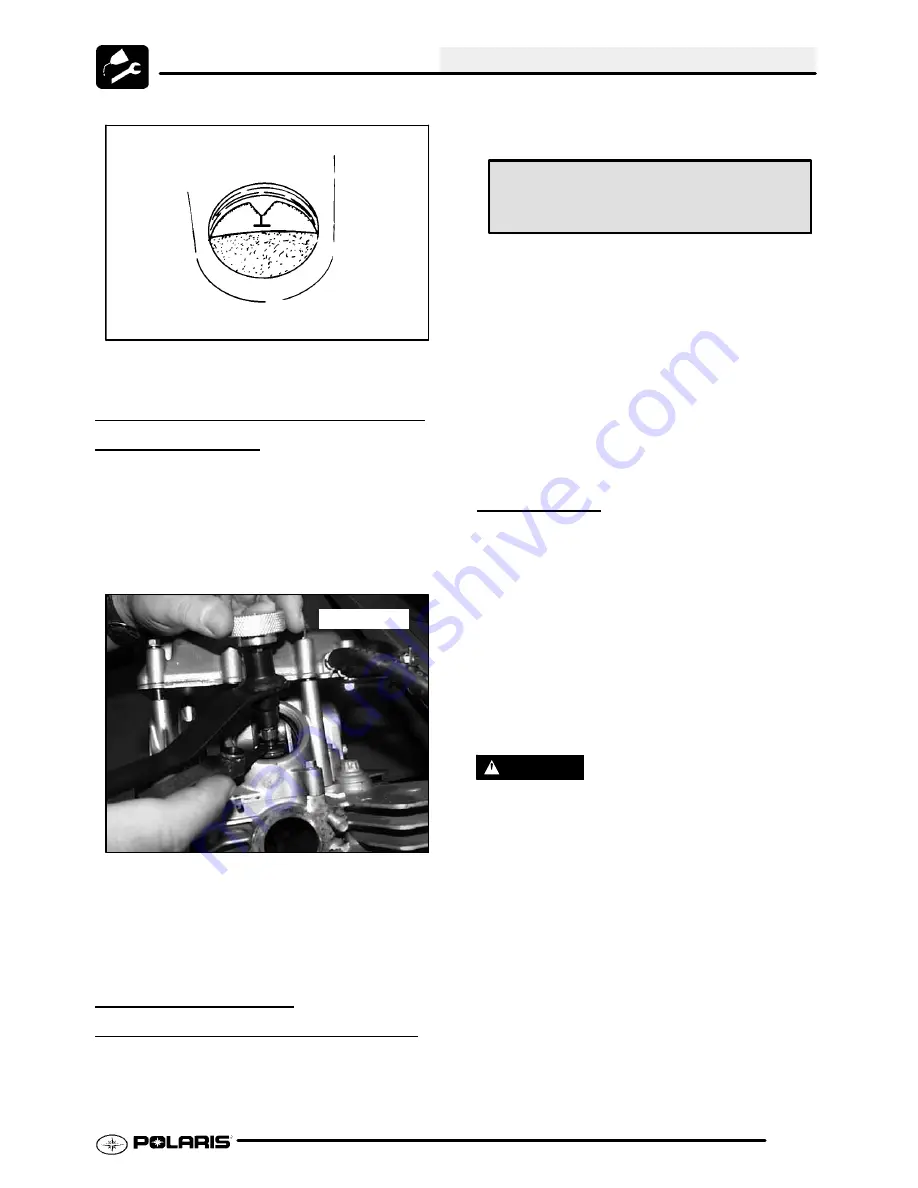

1.

Insert a .006

″

(.15mm) feeler gauge between end

of intake valve stem and clearance adjuster

screw.

2.

Using Valve/Clutch Adjuster (PA--44689), loosen

adjuster lock nut and turn adjusting knob until

there is a slight drag on the feeler gauge.

330 Engine

3.

Hold adjuster screw and tighten adjuster lock nut

securely.

4.

Re-check the valve clearance.

5.

Repeat adjustment procedure if necessary until

clearance is correct with locknut secured.

EXHAUST VALVE

CLEARANCE ADJUSTMENT

NOTE: The exhaust valve is adjusted the same as the

intake valve.

1.

Insert .006

″

feeler gauge between end of exhaust

valve stem and adjuster screw.

EXHAUST VALVE CLEARANCE:

0.006

±

0.0008

I

(0.15

±

0.02 mm)

BTDC on compression

2.

Loosen locknut and turn adjuster screw until there

is a slight drag on feeler gauge.

3.

When clearance is correct, hold adjuster screw

and tighten locknut securely

4.

Re-check the valve clearance.

5.

Repeat adjustment procedure if necessary until

clearance is correct with locknut secured.

6.

Inspect o-rings on the plastic valve plugs, replace

if damaged. Securely fasten valve plugs.

7.

Reinstall fuel tank and any body panels that were

removed to gain access.

STEERING

The steering components should be checked

periodically for loose fasteners, worn tie rod ends, and

damage. Also check to make sure all cotter pins are

in place. If cotter pins are removed, they must not be

re-used. Always use new cotter pins.

Replace any worn or damaged steering components.

Steering should move freely through entire range of

travel without binding. Check routing of all cables,

hoses, and wiring to be sure the steering mechanism

is not restricted or limited. NOTE: Whenever steering

components are replaced, check front end alignment.

Use only genuine Polaris parts.

WARNING

NOTE: Due to the critical nature of the procedures

outlined in this chapter, Polaris recommends steering

component repair and adjustment be performed by an

authorized Polaris Dealer. Only a qualified technician

should replace worn or damaged steering parts. Use

only genuine Polaris replacement parts.

One of two methods can be used to measure toe

alignment: The string method and the chalk method.

If adjustment is required, refer to following pages for

procedure.

PartShark.com

877-999-5686

Summary of Contents for 2009 Trail Blazer 330

Page 94: ...ENGINE 3 48 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 110: ...FUEL SYSTEM CARBURETION 4 16 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 124: ...BODY STEERING SUSPENSION 5 14 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 196: ...ELECTRICAL 10 4 REVERSE LIMIT SYSTEM P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 226: ...ELECTRICAL 10 34 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 227: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 228: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 229: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 230: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...