Summary of Contents for 600 Dragon SP

Page 1: ...2004 SPORTSMAN 600 700 SERVICE MANUAL PN 9918803 ...

Page 138: ...BODY STEERING SUSPENSION 5 16 NOTES ...

Page 210: ...FINAL DRIVE 7 38 NOTES ...

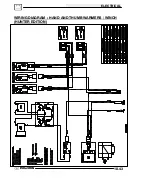

Page 293: ...ELECTRICAL 10 43 WIRING DIAGRAM HAND AND THUMB WARMERS WINCH HUNTER EDITION ...

Page 294: ...ELECTRICAL 10 44 NOTES ...

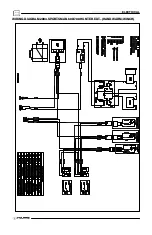

Page 300: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 MODELS WITH FUEL GAUGE NOTES ...

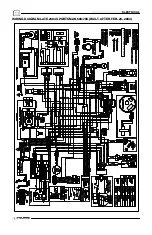

Page 301: ...ELECTRICAL WIRING DIAGRAM 2004 SPORTSMAN 600 700 HUNTER EDT HAND WARM WINCH ...

Page 308: ...PN 9918803 Printed in USA ...