MAINTENANCE

2.27

TOE ALIGNMENT

ADJUSTMENT

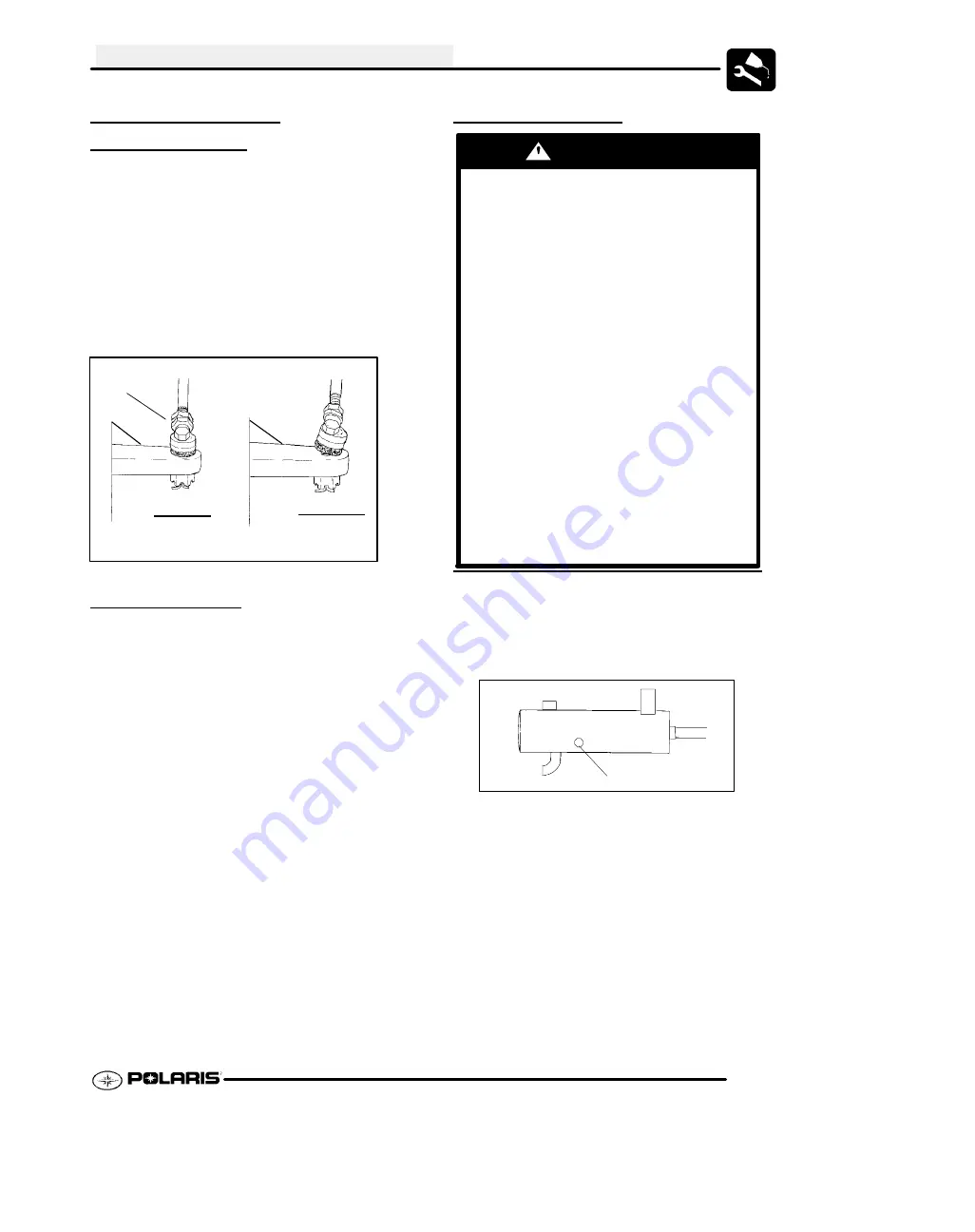

If toe alignment is incorrect, measure the distance

between vehicle center and each wheel. This will tell

you which tie rod needs adjusting.

NOTE:

Be sure

handlebars are straight ahead before determining

which tie rod(s) need adjustment.

CAUTION:

During tie rod adjustment, it is very

important that the following precautions be taken

when tightening tie rod end jam nuts. If the rod end

is positioned incorrectly it will not pivot, and may

break.

Incorrectly

Tightened

Jam Nut

Correctly

Tightened

Jam Nut

Hold

Rod End

Ill.2

Ill.2

To adjust toe alignment:

G

Hold tie rod end to keep it from

rotating.

G

Loosen jam nuts at both end of the tie

rod.

G

Shorten or lengthen the tie rod until

alignment is as required to achieve

the proper toe setting as specified

in Method 1 or Method 2.

G

IMPORTANT:

When tightening the

tie rod end jam nuts, the rod ends

must be held parallel to prevent rod

end damage and premature wear.

Damage may not be immediately

apparent if done incorrectly. See

illustration 2.

G

After alignment is complete, torque

jam nuts to 12-14 ft. lbs. (16-19 Nm).

EXHAUST PIPE

WARNING

G

Do not perform clean out immediately

after the engine has been run, as the ex-

haust system becomes very hot. Serious

burns could result from contact with ex-

haust components.

G

To reduce fire hazard, make sure that

there are no combustible materials in the

area when purging the spark arrestor.

G

Wear eye protection.

G

Do not stand behind or in front of the ve-

hicle while purging the carbon from the

spark arrestor.

G

Never run the engine in an enclosed

area. Exhaust contains poisonous car-

bon monoxide gas.

G

Do not go under the machine while it is

inclined. Set the hand brake and block

the wheels to prevent roll back.

Failure to heed these warnings could result in

serious personal injury or death.

The exhaust pipe must be periodically purged of

accumulated carbon as follows:

1. Remove the clean out plugs located on the

bottom of the muffler as shown in illustration 1.

Clean Out Plug

Ill.1

2. Place the transmission in neutral and start the

engine. Purge accumulated carbon from the

system by momentarily revving the engine

several times.

3. If some carbon is expelled, cover the exhaust

outlet and rap on the pipe around the clean out

plugs while revving the engine several more

times.

4. If particles are still suspected to be in the muffler,

back the machine onto an incline so the rear of the

machine is one foot higher than the front. Set the

hand brake and block the wheels. Make sure the

machine is in neutral and repeat Steps 2 and 3.

SEE WARNING

Summary of Contents for 600 Dragon SP

Page 1: ...2004 SPORTSMAN 600 700 SERVICE MANUAL PN 9918803 ...

Page 138: ...BODY STEERING SUSPENSION 5 16 NOTES ...

Page 210: ...FINAL DRIVE 7 38 NOTES ...

Page 293: ...ELECTRICAL 10 43 WIRING DIAGRAM HAND AND THUMB WARMERS WINCH HUNTER EDITION ...

Page 294: ...ELECTRICAL 10 44 NOTES ...

Page 300: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 MODELS WITH FUEL GAUGE NOTES ...

Page 301: ...ELECTRICAL WIRING DIAGRAM 2004 SPORTSMAN 600 700 HUNTER EDT HAND WARM WINCH ...

Page 308: ...PN 9918803 Printed in USA ...