MAINTENANCE

2.16

VENT LINES

Check fuel tank, oil tank, carburetor, battery and

transmission vent lines for signs of wear,

deterioration, damage or leakage. Replace every two

years.

Be sure vent lines are routed properly and secured

with cable ties.

CAUTION:

Make sure lines are not

kinked or pinched.

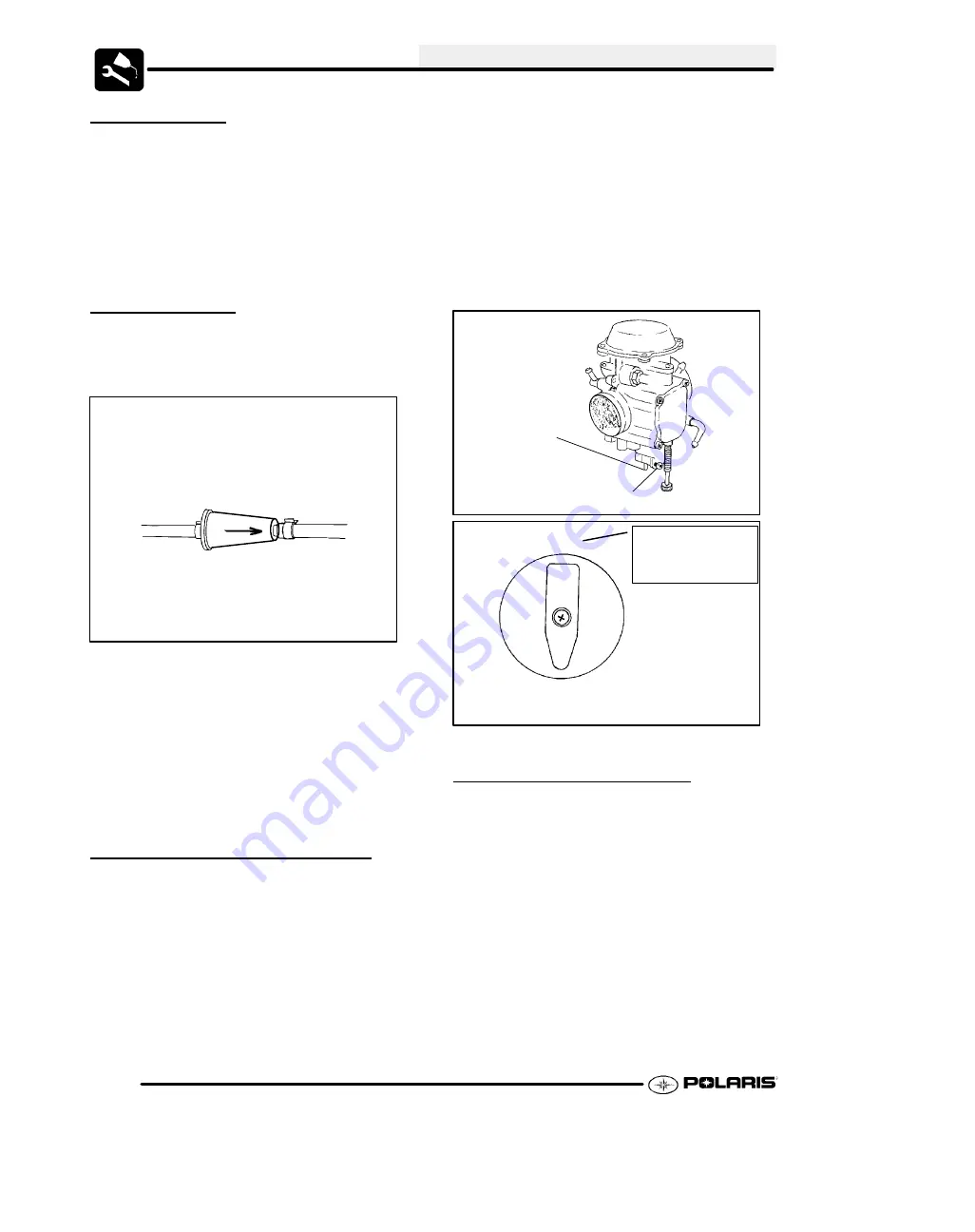

FUEL FILTER

The fuel filter should be replaced in accordance with

the Periodic Maintenance Chart or whenever

sediment is visible in the filter.

Arrow Indicates Direction

of Flow

To Carburetor

Ill. 2

1. Shut off fuel supply at fuel valve.

2. Remove line clamps at both ends of the filter.

3. Remove fuel lines from filter.

4. Install new filter and clamps onto fuel lines with

arrow pointed in direction of fuel flow.

5. Install clamps on fuel line.

6. Turn fuel valve “ON”.

7. Start engine and inspect for leaks.

CARBURETOR DRAINING

The carburetor float bowl should be drained

periodically to remove moisture or sediment from the

bowl, or before extended periods of storage.

NOTE:

The bowl drain screw is located on the bottom

left side of the float bowl.

1. Turn fuel valve to the off position.

2. Place a clean container beneath the bowl drain

spigot or bowl drain hose.

3. Turn drain screw out two turns and allow fuel in

the float bowl and fuel line to drain completely.

4. Inspect the drained fuel for water or sediment.

5. Tighten drain screw.

6. Turn fuel valve to “ON”.

7. Start machine and check for leaks.

NOTE:

All tubes attached to the carburetor must be

check for pinching or blockage, as this will effect

engine performance.

Drain tube

attached

here

Drain Screw

Ill. 1

ON

OFF

RES

Ill. 2

NOTE: Late build

2004 models do not

have the reserve

option.

COMPRESSION TEST

NOTE:

This engine does NOT have decompression

components. Compression readings will vary in

proportion to cranking speed during the test. Average

compression (measured) is about

150-170 psi

during

a compression test.

A smooth idle generally indicates good compression.

Low engine compression is rarely a factor in running

condition problems above idle speed. Abnormally

high compression can be caused by carbon deposits

in the combustion chamber or worn, damaged

exhaust cam lobes.

Inspect camshaft and

combustion chamber if compression is abnormally

high.

Summary of Contents for 600 Dragon SP

Page 1: ...2004 SPORTSMAN 600 700 SERVICE MANUAL PN 9918803 ...

Page 138: ...BODY STEERING SUSPENSION 5 16 NOTES ...

Page 210: ...FINAL DRIVE 7 38 NOTES ...

Page 293: ...ELECTRICAL 10 43 WIRING DIAGRAM HAND AND THUMB WARMERS WINCH HUNTER EDITION ...

Page 294: ...ELECTRICAL 10 44 NOTES ...

Page 300: ...ELECTRICAL WIRING DIAGRAM LATE 2004 SPORTSMAN 600 700 MODELS WITH FUEL GAUGE NOTES ...

Page 301: ...ELECTRICAL WIRING DIAGRAM 2004 SPORTSMAN 600 700 HUNTER EDT HAND WARM WINCH ...

Page 308: ...PN 9918803 Printed in USA ...