79

MAINTENANCE AND LUBRICATION

Filter Systems

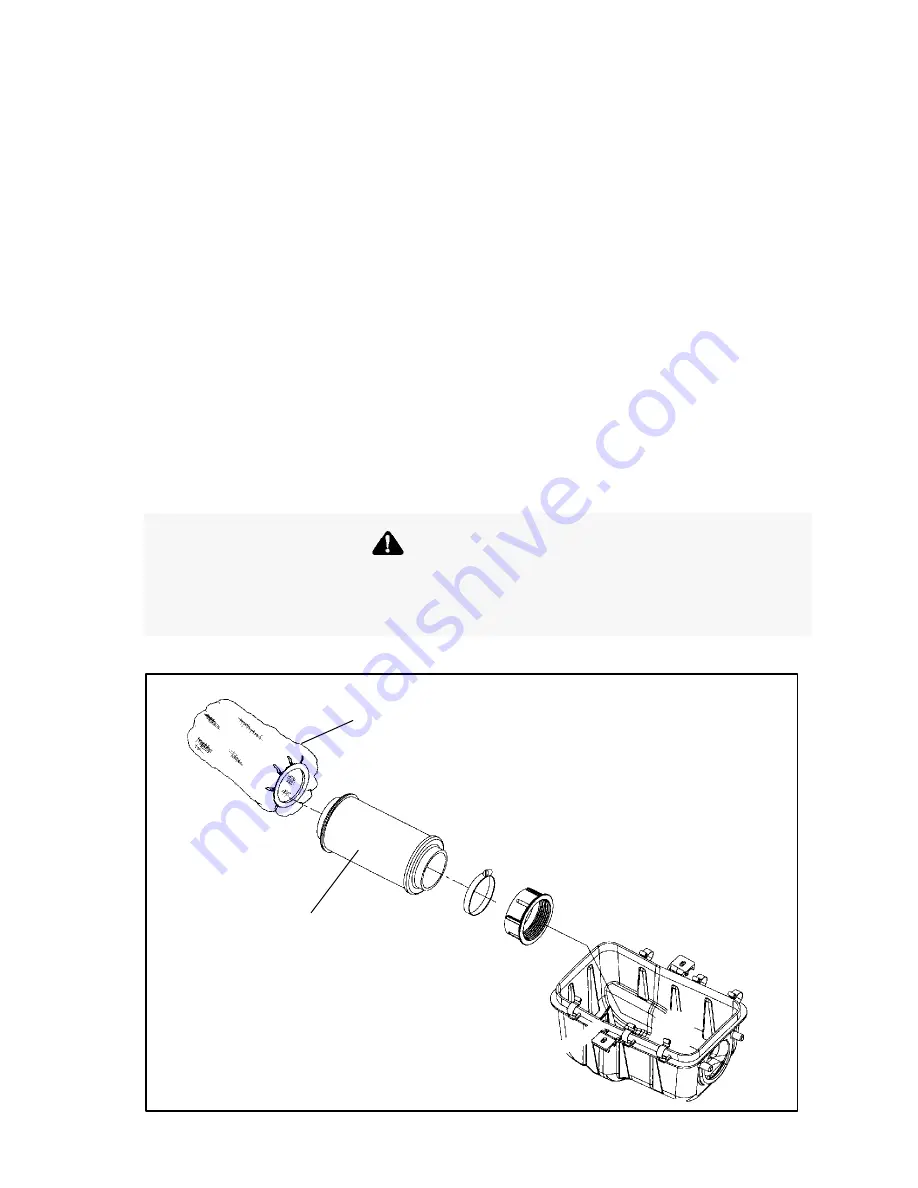

Air Filter Service

Polaris recommends that the air filter be replaced annually. When

riding in extremely dusty conditions, replace it more often.

1. Remove the seat.

2. Remove the spring clamps securing the air box lid and remove the

lid.

3. Loosen the clamp and remove the filter.

4. Remove the fabric type pre-filter (1) from the main filter (2). Wash

the pre-filter in soapy water, rinse and allow to dry thoroughly.

5. Reinstall the pre-filter over the main filter. (Replace the main filter

if necessary.)

6. Reinstall the filter into the air box and tighten the clamp. Do not

over-tighten the clamp or filter damage may occur.

CAUTION

Operating the vehicle without a pre-filter can cause engine

damage. Always reinstall the pre-filter before operating.

2

1