3.72

9928487 R01 - 2018 RANGER XP 1000 Service Manual

© Copyright Polaris Industries Inc.

FLYWHEEL INSTALLATION

1. If previously removed, reinstall the flywheel key.

2. Inspect and clean crankshaft and flywheel taper with

isopropyl

alcohol

or

similar

cleaning

solution.

Replace crankshaft if surface damage is present.

Clean taper of crankshaft to remove all oil or grease.

3. Using an applicator, apply a 360 degree bead of

Loctite 641 (Yellow) to the internal taper surface on

the flywheel. Apply Loctite bead 5-6 mm from the

center of the taper, offset to the larger diameter of the

taper on the flywheel.

4. Using an applicator, apply a 360 degree bead of

Loctite 641 (Yellow) to the external taper surface on

the crankshaft. Apply Loctite bead 5-6 mm from the

center of the taper and offset to the smaller end on

the crankshaft. Be careful to not apply any Loctite to

the starter gear bearing.

5. Align flywheel key-way with key and install the

flywheel, seating it fully on taper.

6. Install

flywheel

retaining

bolt

q

.

Using

a

commercially available strap wrench , hold flywheel

w

and torque the retaining bolt to specification.

NOTE

If the Cylinder Holding & Camshaft Timing Plate (

PU-

50563

) is installed, remove it before tightening the

flywheel.

TORQUE

Flywheel Retaining Bolt:

Step 1: 133 ft-lbs (180 Nm)

Step 2: Back out bolt 180° & retorque to spec.

7. Wipe off excess Loctite and let stand for 1 hour

before starting engine.

NOTE

Loctite cures with time, the longer the unit is let stand

before engine starting the better the joint will be.

8. Install the starter torque limit gear as an assembly.

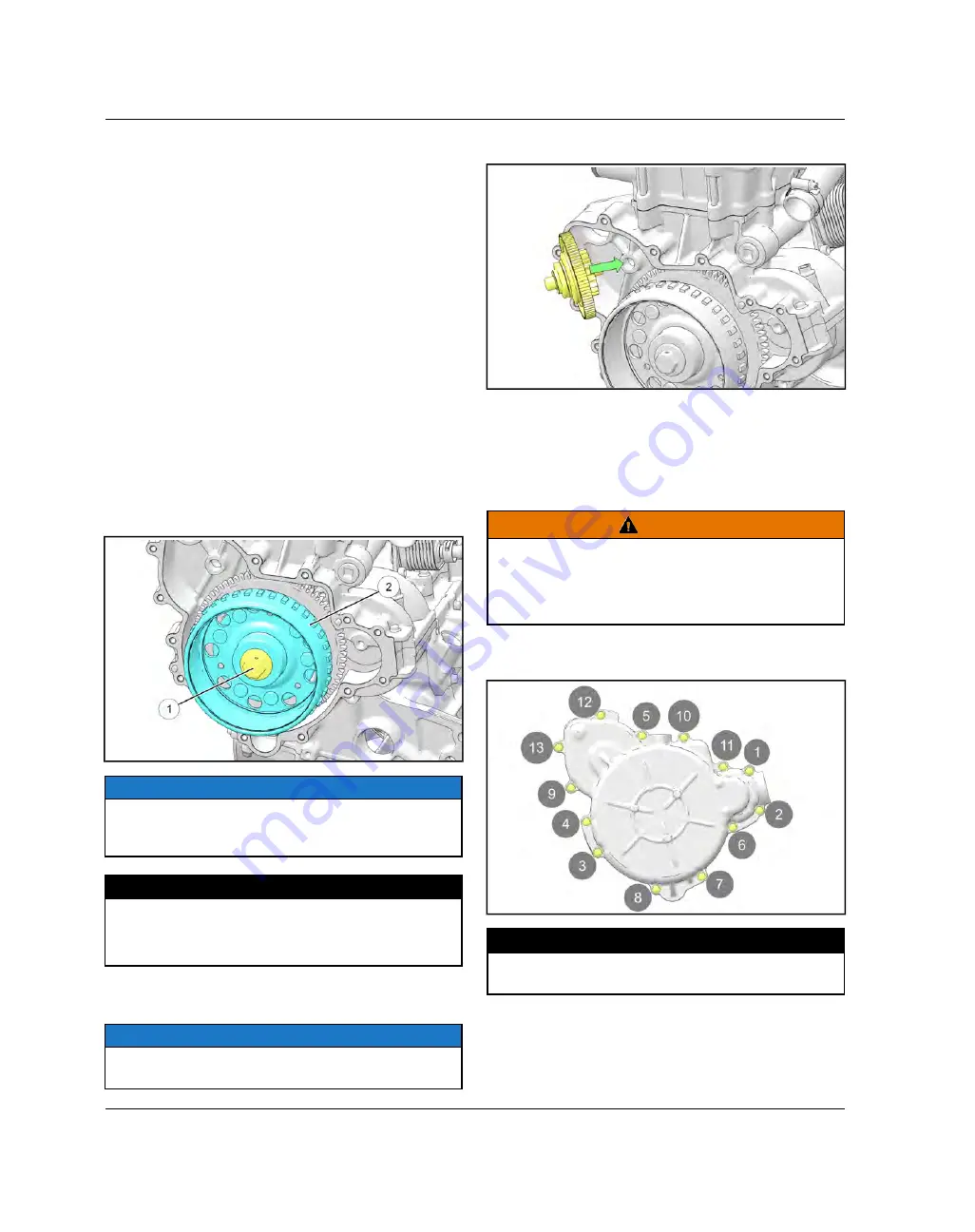

STATOR COVER INSTALLATION

1. Apply gasket tack adhesive to help hold gasket in

place during assembly.

2. Install a new stator cover gasket over alignment pins.

CAUTION

The flywheel contains powerful magnets. Use caution

when removing and installing the stator cover. DO NOT

place fingers between cover and crankcase at any time

during the removal / installation process or injury could

result.

3. Install stator cover and thirteen screws. Torque

screws in sequence to specification.

TORQUE

Stator Cover Screws:

9 ft-lbs (12 Nm)