9928487 R01 - 2018 RANGER XP 1000 Service Manual

© Copyright Polaris Industries Inc.

3.129

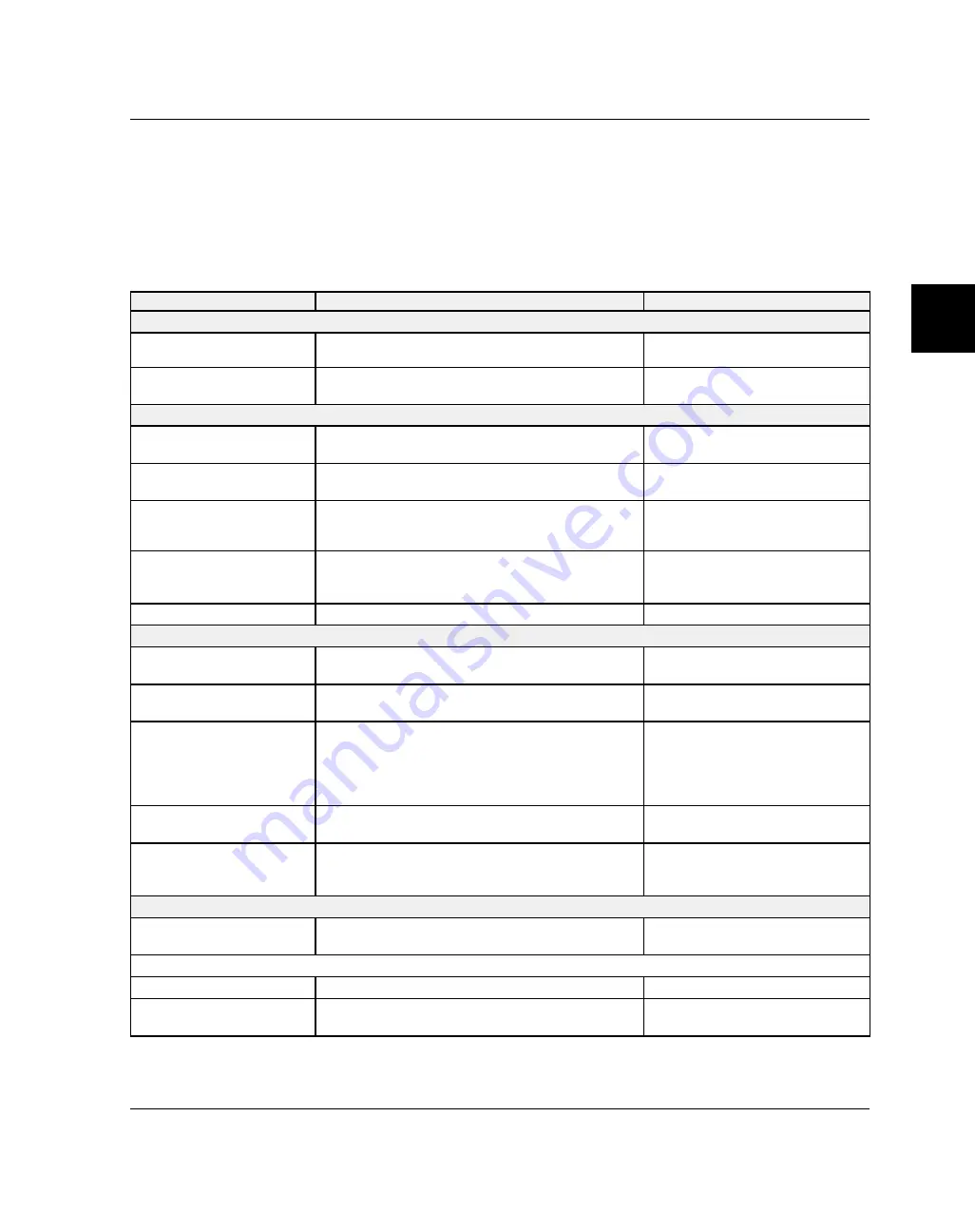

GAUGE PRESSURE RELATED

TROUBLESHOOTING

Normal compressor suction (low side) and discharge (high side) pressure at ambient temperatures of 86 - 96°F (30 -

38°C) and compressor speed of approximately 2000 rpm are:

• High pressure side pressure: 210 - 265 psi (1448 -

1827 kPa)

• Low pressure side pressure: 15 - 33 psi (103 - 228

kPa)

As a rule of thumb the high side pressure will be around eight times greater then the low side pressure.

SYMPTOM

POSSIBLE CAUSE

SOLUTION

Low pressure side too high

1. Expansion valve opens

too far.

Frost is present on the suction hose.

Replace expansion valve.

2. Dective compressor.

The high and low pressure side gauge pressures

equalize when the magnetic clutch is engaged.

Replace compressor.

Low pressure side too low

1. Low refrigerant charge.

The high side pressure will be low and bubbles

may be present in sight glass on receive drier.

Repair leaks and recharge the

refrigerant to the correct level.

2. Clogged or closed

expansion valve.

The expansion valve’s inlet side is frosted.

Moisture or other Contaminants can be the cause.

Clean or replace the expansion

Valve.

3. Restriction between

drier and expansion valve.

Frost on the line between drier and expansion

valve. A Negative low pressure reading may be

shown.

Flush system or replace hose.

4. Thermostat malfunction.

The evaporator is frozen.

Adjust themostat’s temperature

setting or probe placement or

replace thermostat.

5. Receiver drier restriction

Excessive frost on receiver drier.

Replace receiver drier.

High pressure side too high

1. Poor condenser

performance.

Dirty or clogged condenser fins. Condenser fans

not Operating.

Clean fins, and / or repair the fan.

2. Excessive refrigerant.

The high pressure side pressure will be high.

Evacuate and recharge to correct

refrigerant level.

3. Excessive oil charge.

The high pressure side will be high.

Evacuate system. Remove oil

from condenser and compressor.

Add correct oil charge back into

compressor. Flush system with

nitrogen. Replace drier.

4. Air in system.

Pressure is high on both high and low sides.

Evacuate and recharge with

Refrigerant.

5. Restriction in drier,

condenser or high

pressure line.

High pressure side will be high, and low pressure

side will be low.

Evacuate and flush system

replacing defective parts.

High pressure side too low

1. Low refrigerant charge.

The high side pressure will be low and bubbles

may be present in sight glass on receive drier.

Repair any leaks and recharge

the refrigerant to the correct level.

System pressures equal

1. Clutch not operating.

See compressor clutch related topics above.

2. Compressor not

pumping.

Equal high and low pressures.

Replace compressor.